COVID-19 and VTScada Remote Interactive Training

For the safety of our customers and staff, we have canceled all in-person training courses until further notice. To ensure access to the training, we are pleased to offer Remote Interactive Training Courses. These are the same as in-person courses, except the instructor is on your screen instead of in the room. See a list of available courses below. A Remote Interactive Training Course includes:

- A live instructor, not a recording.

- Interaction with the instructor, just like they were in the room; ask questions whenever you want.

- The opportunity for one-on-one instruction in the form of breakout rooms during the course.

- If you get stuck, you can share your screen with the instructor without worrying about who else is watching. The instructor can even take control for a few minutes to help guide you back on track.

- At the end of the course, you’ll have access to a recording of the entire session. Review any bits that you missed or need a refresher on. (Breakout rooms and one-on-one sessions are not recorded.)

- The pace, timing, material, and exercises are all the same as if you were present in a classroom.

Upcoming Training Courses

Courses listed below will be updated on demand.

Courses listed below will be updated on demand.

| DATES |

COURSE TYPE |

LOCATION |

STATUS |

|

| Sep 21 – Sep 24, 2020 |

Advanced Configuration |

Remote Interactive Training |

Open |

Please call 905-760-9399 to register |

| Dec 7 – Dec 10, 2020 |

Operation & Configuration |

Remote Interactive Training |

Open |

Please call 905-760-9399 to register |

Courses Descriptions and Materials

LEVEL I – Operation & Configuration Course

Operators and developers will learn about the many features of the VTScada monitoring and control software by creating a working, full-featured application from start to finish. This course will explain how to use the native display screens, connect to hardware, build new displays, work with alarms, configure security and much more.

LEVEL 2 – Advanced Configuration

Experienced VTScada developers will learn advanced configuration techniques that allow them to go beyond the standard tools for building their applications. Knowledge of the topics covered in the Operation and Configuration course is recommended for anyone considering this advanced course.

Request a Course at Your Location

Contact Larry McLean to request an onsite customized training course.

Student Course Requirements

For In-Class Courses

- A Windows 10® laptop is required. Let us know if you need us to provide one – numbers are limited. See the OS & PC requirements.

- Travel and lodging arrangements are the responsibility of attendees.

- Spaces are limited, so please respond as soon as possible.

For Remote Interactive Training Courses

- A computer, on which you can install and run VTScada.

- A reasonably fast internet connection.

- A workspace where you can focus on the course.

- A working webcam. (Usually built into your laptop or tablet.) This will make you part of the class, not just a disembodied connection in a list.

- Headphones or a headset. These are not needed if you’re in a quiet space, or away from co-workers who don’t want to listen to the course broadcast from your computer speakers.

- A working microphone, either as part of your computer, headset, or webcam.

- Optional: A second screen, whether that’s a second monitor, a second laptop or a tablet. This allows you to have the course workbook file and the Remote Interactive Training session open on one screen while doing your exercises on another.

- If co-workers are attending the class with you, consider using a projector and sharing one set of speakers and a microphone, rather than having everyone run a separate copy of the virtual classroom. This will avoid audio feedback and reduce the load on your network connection. A webcam pointing back at the group is recommended.

- Ensure that any Bluetooth devices you are using are fully charged.

Continuing Education Credits

VTSCADA Operation & Configuration Course is approved for Continuing Ed Credits in the states of Florida, South Carolina, Louisiana, Tennessee, as well as the provinces of Nova Scotia, New Brunswick, Newfoundland & Labrador, and Prince Edward Island.

Video Tutorials

Get started using VTScada by checking out

Video Tutorials.

More Information

- Larry McLean: Email or phone: 866.342.5222 Ext. 236

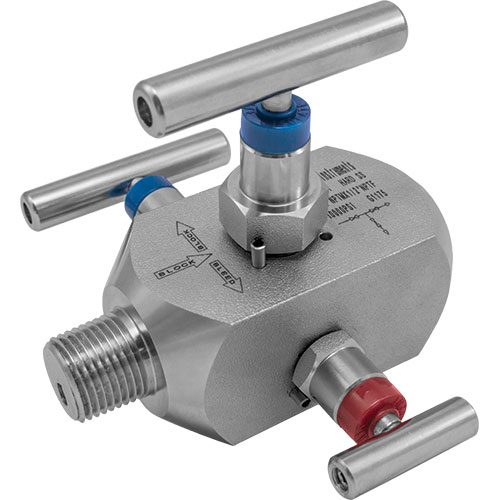

The MS 2500 flanged sensor are well suited for all application and flow ranges. The MS2500 is available in the widest range of diameters.

Features;

• Accuracy to +/-0.2% of rate from 1 to 33 ft/sec.

• Nineteen sizes from 1" to 48" Pipe Diameters.

• Flow ranges from 2.37 to 179,400 GPM.

• Pressures to 5600 PSI.

• Volumetric flow rate measurement independent of fluid viscosity, density and temperature.

• No moving parts for zero maintenance.

• Bi-directional flow measurement.

• No pressure drop through sensor.

• Optional Integral ground electrode eliminates grounding rings with plastic piping systems.

• Minimal straight pipe run required.

• Every sensor is factory wet-calibrated.

The MS 2500 flanged sensor are well suited for all application and flow ranges. The MS2500 is available in the widest range of diameters.

Features;

• Accuracy to +/-0.2% of rate from 1 to 33 ft/sec.

• Nineteen sizes from 1" to 48" Pipe Diameters.

• Flow ranges from 2.37 to 179,400 GPM.

• Pressures to 5600 PSI.

• Volumetric flow rate measurement independent of fluid viscosity, density and temperature.

• No moving parts for zero maintenance.

• Bi-directional flow measurement.

• No pressure drop through sensor.

• Optional Integral ground electrode eliminates grounding rings with plastic piping systems.

• Minimal straight pipe run required.

• Every sensor is factory wet-calibrated.