Moore Industries’ universal PSD PC-Programmable Loop Display features a large integral display that shows real-time process status in mA, percent, or any designated 5-character Engineering units (EGU). Superior Accuracy–The loop-powered PSD reads any 4-20mA signal and displays the information with phenomenal accuracy of ±0.012% of input scale. And because it requires less than 2.3 Volts, it won’t burden most loops. Simple and Versatile PC Setup Program– Using the PC software, the PSD can either be custom scaled to display in a percent or scaled directly into engineering units for indicating process measurements such as pressure, temperature, level, or fl ow. Span, zero, input range, display range, and fi ltering frequency can also be easily programmed. Our software will even capture the input range limits of the loop to provide you with the most accurate display available

Adroit Smart SCADA System designed for process control, manufacturing systems and open automation applications. Adroit 8.0 is developed on the .NET platform and is compatible with various Microsoft operating systems. Adroit 8.0 has a flexible, object-oriented, client server architecture that supports any system from a stand-alone implementation to an installation spanning multiple distributed sites. Adroit is built on a client-server architecture, where the Agent Server (I/O Server) communicates with field devices and performs the Server functions of scanning, logging, alarming and value processing. The Client side (Classic and Smart User lntefaces) provides the capability of configuring, displaying, manipulating and delivering the values in a rich, secure user interface.

Adroit Smart SCADA System designed for process control, manufacturing systems and open automation applications. Adroit 8.0 is developed on the .NET platform and is compatible with various Microsoft operating systems. Adroit 8.0 has a flexible, object-oriented, client server architecture that supports any system from a stand-alone implementation to an installation spanning multiple distributed sites. Adroit is built on a client-server architecture, where the Agent Server (I/O Server) communicates with field devices and performs the Server functions of scanning, logging, alarming and value processing. The Client side (Classic and Smart User lntefaces) provides the capability of configuring, displaying, manipulating and delivering the values in a rich, secure user interface.

Circulation Heaters Type Ex. Designed for forced flow or natural flow applications. Standard designs ranging from 0.6 to 672kW… higher kWratings are also available.Optional features include built in high limits and thermostats, stainless steel wetted parts. moisture resistant or explosion-proof housings. CRN registered vessels for Canada. Authorized to bear the U and N stamps, depending on ASME code classification (Section VIII or III)

Circulation Heaters Type Ex. Designed for forced flow or natural flow applications. Standard designs ranging from 0.6 to 672kW… higher kWratings are also available.Optional features include built in high limits and thermostats, stainless steel wetted parts. moisture resistant or explosion-proof housings. CRN registered vessels for Canada. Authorized to bear the U and N stamps, depending on ASME code classification (Section VIII or III)

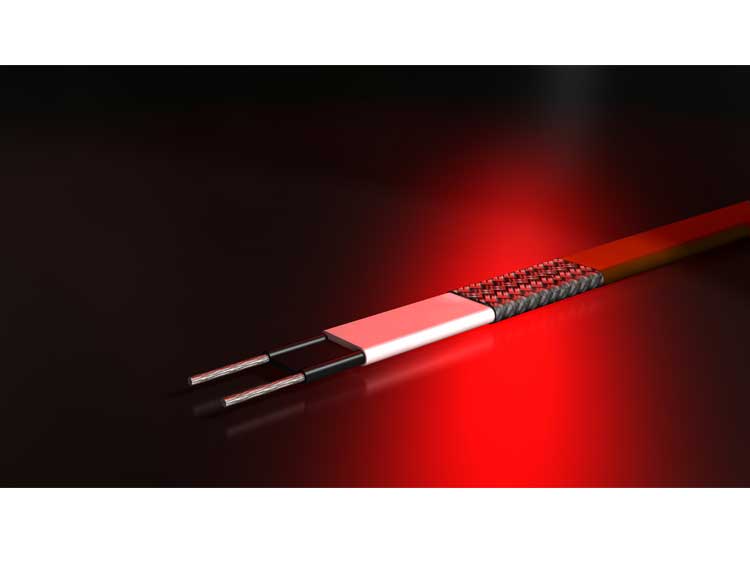

Self-regulating heating cables consist of two parallel bus wires embedded in a networked plastic heating element, doped with surrounding carbon particles. If the temperature increases during operation, the plastic expands due to molecular expansion and the distance between the carbon particles increases. Resistance increases and output drops. When it cools down, this process is reversed and output increases.

This physical property provides several benefits, including the ability to overlap the self-regulating cable and installation without the requirement of a temperature cut-out device.

Benefits:

Self-regulating heating cables consist of two parallel bus wires embedded in a networked plastic heating element, doped with surrounding carbon particles. If the temperature increases during operation, the plastic expands due to molecular expansion and the distance between the carbon particles increases. Resistance increases and output drops. When it cools down, this process is reversed and output increases.

This physical property provides several benefits, including the ability to overlap the self-regulating cable and installation without the requirement of a temperature cut-out device.

Benefits:

Corrective action prompted by early warning of generator overheating can mean the difference between a brief shutdown for minor repairs and a major overhaul involving weeks or even months of costly downtime. E/One pioneered the development of the Generator Condition Monitor (GCM) and in more than 1,500 applications worldwide, operators have the opportunity of taking corrective action if and when a critical situation occurs

Corrective action prompted by early warning of generator overheating can mean the difference between a brief shutdown for minor repairs and a major overhaul involving weeks or even months of costly downtime. E/One pioneered the development of the Generator Condition Monitor (GCM) and in more than 1,500 applications worldwide, operators have the opportunity of taking corrective action if and when a critical situation occurs

PP1H and PP2H Peristaltic Pump Chemical Feed Prepackaged Systems . SELF PRIMING WITH BUILT IN SPILL AND LEAK PREVENTION The PP1H and PP2H (dual pump model) an ideal choice for hard-to-handle chemicals such as sodium hypochlorite, hydrogen peroxide or viscous polymers. Flow rates from .004 to 98 gallons per hour (with dual pump-head option.)

PP1H and PP2H Peristaltic Pump Chemical Feed Prepackaged Systems . SELF PRIMING WITH BUILT IN SPILL AND LEAK PREVENTION The PP1H and PP2H (dual pump model) an ideal choice for hard-to-handle chemicals such as sodium hypochlorite, hydrogen peroxide or viscous polymers. Flow rates from .004 to 98 gallons per hour (with dual pump-head option.)

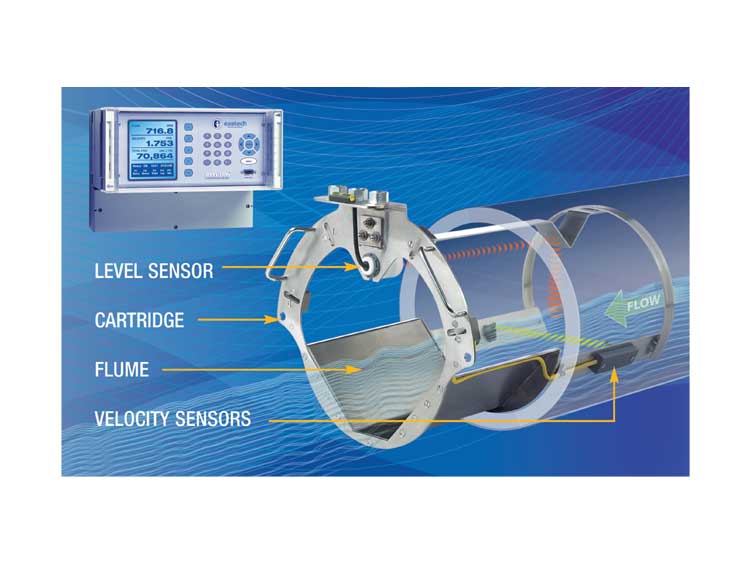

The Cartridge Meter is the first open channel flowmeter to utilize hybrid technology. The new technology combines a traceable U.S. Bureau of Reclamation flume/level system for low flow applications with the more accurate EPA proven transit-time chordal velocity method for high flow applications. This new hybrid technology system allows for precise and highly accurate flow measurement during extremely low flows, high flows, surcharges, reverse flows, stagnation and non-uniform hydraulic profiles.

The Cartridge Meter is the first open channel flowmeter to utilize hybrid technology. The new technology combines a traceable U.S. Bureau of Reclamation flume/level system for low flow applications with the more accurate EPA proven transit-time chordal velocity method for high flow applications. This new hybrid technology system allows for precise and highly accurate flow measurement during extremely low flows, high flows, surcharges, reverse flows, stagnation and non-uniform hydraulic profiles.

The F010 is a local weather-proof indicator with large 26mm (1”) high digits which displays the actual flow rate. The measuring and time unit to be displayed below the flow rate are simply selected through an alphanumeric configuration menu. The configuration of K-factors or Span and number of decimals is done through software functions without any sensitive DIP-switches or trimmers.

The F010 is a local weather-proof indicator with large 26mm (1”) high digits which displays the actual flow rate. The measuring and time unit to be displayed below the flow rate are simply selected through an alphanumeric configuration menu. The configuration of K-factors or Span and number of decimals is done through software functions without any sensitive DIP-switches or trimmers.

The MS 2500 flanged sensor are well suited for all application and flow ranges. The MS2500 is available in the widest range of diameters.

Features;

• Accuracy to +/-0.2% of rate from 1 to 33 ft/sec.

• Nineteen sizes from 1" to 48" Pipe Diameters.

• Flow ranges from 2.37 to 179,400 GPM.

• Pressures to 5600 PSI.

• Volumetric flow rate measurement independent of fluid viscosity, density and temperature.

• No moving parts for zero maintenance.

• Bi-directional flow measurement.

• No pressure drop through sensor.

• Optional Integral ground electrode eliminates grounding rings with plastic piping systems.

• Minimal straight pipe run required.

• Every sensor is factory wet-calibrated.

The MS 2500 flanged sensor are well suited for all application and flow ranges. The MS2500 is available in the widest range of diameters.

Features;

• Accuracy to +/-0.2% of rate from 1 to 33 ft/sec.

• Nineteen sizes from 1" to 48" Pipe Diameters.

• Flow ranges from 2.37 to 179,400 GPM.

• Pressures to 5600 PSI.

• Volumetric flow rate measurement independent of fluid viscosity, density and temperature.

• No moving parts for zero maintenance.

• Bi-directional flow measurement.

• No pressure drop through sensor.

• Optional Integral ground electrode eliminates grounding rings with plastic piping systems.

• Minimal straight pipe run required.

• Every sensor is factory wet-calibrated.

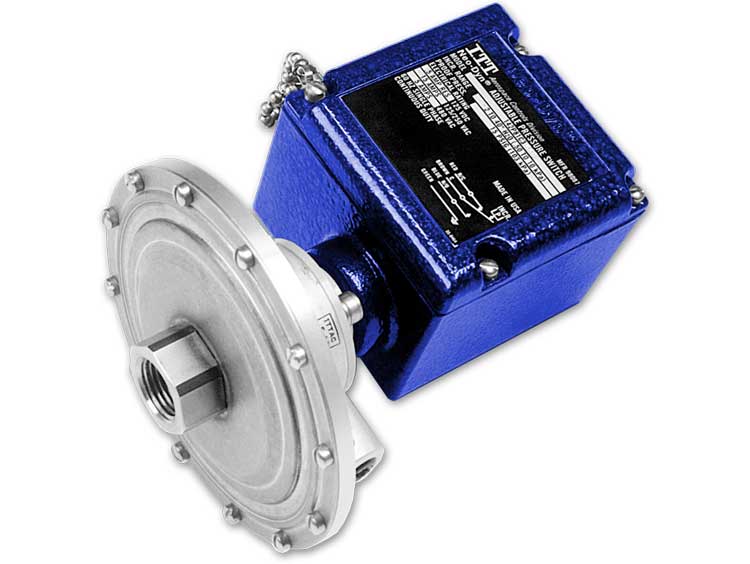

Series 100P (diaphragm sensor) for pneumatic and low impulse hydraulics up to 3000 psig system pressure

Versatile Nega-Rate® Belleville disc spring pressure switch for a wide range of applications.

Specifications

• Electrical: Snap action electrical switch recognized by Underwriters’ Laboratories, Inc. and CSA International

• Electrical Connection: 1/2 NPT female conduit connection with terminal block

• Pressure Connection:

o Wetted Material 1 1/4 NPT Female

o Wetted Material 4, 5, 7 and 9 1/2 NPT Female

• Temperature Range

o Ambient: -40°F to +180°F (-40°C to +82°C)

o Media: -40°F to +300°F (-40°C to +149°C)

• Media temperature limits change with O-Ring selection

• Adjustment: Concealed wrench flat adjustment with range scale

• Shipping Weight: Approximately 3 pounds

Series 100P (diaphragm sensor) for pneumatic and low impulse hydraulics up to 3000 psig system pressure

Versatile Nega-Rate® Belleville disc spring pressure switch for a wide range of applications.

Specifications

• Electrical: Snap action electrical switch recognized by Underwriters’ Laboratories, Inc. and CSA International

• Electrical Connection: 1/2 NPT female conduit connection with terminal block

• Pressure Connection:

o Wetted Material 1 1/4 NPT Female

o Wetted Material 4, 5, 7 and 9 1/2 NPT Female

• Temperature Range

o Ambient: -40°F to +180°F (-40°C to +82°C)

o Media: -40°F to +300°F (-40°C to +149°C)

• Media temperature limits change with O-Ring selection

• Adjustment: Concealed wrench flat adjustment with range scale

• Shipping Weight: Approximately 3 pounds