When Hydrogen purity drops, windage losses and operating costs increase, resulting in lost revenue and profitability. Gas purity is also a critical life safety issue, making monitoring for potentially explosive levels essential. E/One's Hydrogen Control Cabinet (HCC) was designed specifically for monitoring and controlling hydrogen purity in GE generators that utilize scavenging seal oil systems. The HCC contains two independent analyzers that monitor hydrogen purity from both the turbine-end seal drain enlargement and the collector-end seal drain enlargement. Designed to be used in a hazardous location, the HCC has the ability to automatically increase the amount of hydrogen gas bled from the generator. It's also an easy replacement for your old hydrogen control cabinet. Featuring digital displays, warnings and alarms, the HCC works with all GE and non-GE control systems.

Glass fiber reinforced polyester (GRP) enclosure, Ex e and Ex tb certified, 110 mm x 110 mm x 65 mm, Customizable configuration of cable gland types as per specification, Installation in Zone 1, Zone 2, Zone 21 and Zone 22

Glass fiber reinforced polyester (GRP) enclosure, Ex e and Ex tb certified, 110 mm x 110 mm x 65 mm, Customizable configuration of cable gland types as per specification, Installation in Zone 1, Zone 2, Zone 21 and Zone 22

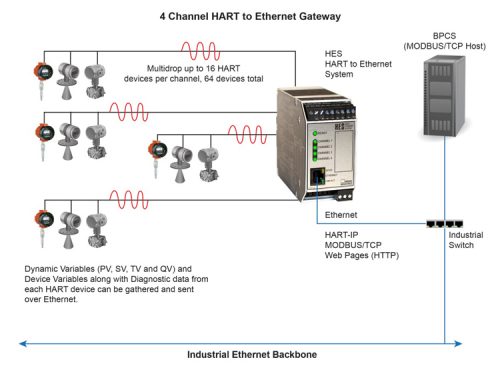

Description The HCS HART Concentrator System converts a HART digital signal to a serial (RS-485 or RS-232) MODBUS RTU communication protocol. This allows HART transmitters and valves to interface directly with MODBUS-based monitoring and control systems.

Description The HCS HART Concentrator System converts a HART digital signal to a serial (RS-485 or RS-232) MODBUS RTU communication protocol. This allows HART transmitters and valves to interface directly with MODBUS-based monitoring and control systems.

When Hydrogen purity drops, windage losses and operating costs increase, resulting in lost revenue and profitability. Gas purity is also a critical life safety issue, making monitoring for potentially explosive levels essential. E/One's Hydrogen Control Cabinet (HCC) was designed specifically for monitoring and controlling hydrogen purity in GE generators that utilize scavenging seal oil systems. The HCC contains two independent analyzers that monitor hydrogen purity from both the turbine-end seal drain enlargement and the collector-end seal drain enlargement. Designed to be used in a hazardous location, the HCC has the ability to automatically increase the amount of hydrogen gas bled from the generator. It's also an easy replacement for your old hydrogen control cabinet. Featuring digital displays, warnings and alarms, the HCC works with all GE and non-GE control systems.

When Hydrogen purity drops, windage losses and operating costs increase, resulting in lost revenue and profitability. Gas purity is also a critical life safety issue, making monitoring for potentially explosive levels essential. E/One's Hydrogen Control Cabinet (HCC) was designed specifically for monitoring and controlling hydrogen purity in GE generators that utilize scavenging seal oil systems. The HCC contains two independent analyzers that monitor hydrogen purity from both the turbine-end seal drain enlargement and the collector-end seal drain enlargement. Designed to be used in a hazardous location, the HCC has the ability to automatically increase the amount of hydrogen gas bled from the generator. It's also an easy replacement for your old hydrogen control cabinet. Featuring digital displays, warnings and alarms, the HCC works with all GE and non-GE control systems.