The F126-EG flow computer has been developed to calculate corrected gas volume at normal conditions. The corrected volumetric flow is calculated by measuring the uncorrected volumetric flow, actual line temperature and pressure which are processed with the equations stored in the flow computer. A compressibility factor can be set to approach a real gas behavior. The reference conditions can be defined as desired (e.g. 15°C or 60°F and 1.013 bar).

The display shows the compensated flow rate, total, accumulated total and the actual line temperature and pressure. On-screen engineering units like Nm³ are easily configured from a comprehensive selection.

The F126-EG flow computer has been developed to calculate corrected gas volume at normal conditions. The corrected volumetric flow is calculated by measuring the uncorrected volumetric flow, actual line temperature and pressure which are processed with the equations stored in the flow computer. A compressibility factor can be set to approach a real gas behavior. The reference conditions can be defined as desired (e.g. 15°C or 60°F and 1.013 bar).

The display shows the compensated flow rate, total, accumulated total and the actual line temperature and pressure. On-screen engineering units like Nm³ are easily configured from a comprehensive selection. -

The F126-EG flow computer has been developed to calculate corrected gas volume at normal conditions. The corrected volumetric flow is calculated by measuring the uncorrected volumetric flow, actual line temperature and pressure which are processed with the equations stored in the flow computer. A compressibility factor can be set to approach a real gas behavior. The reference conditions can be defined as desired (e.g. 15°C or 60°F and 1.013 bar).

The display shows the compensated flow rate, total, accumulated total and the actual line temperature and pressure. On-screen engineering units like Nm³ are easily configured from a comprehensive selection.

The F126-EG flow computer has been developed to calculate corrected gas volume at normal conditions. The corrected volumetric flow is calculated by measuring the uncorrected volumetric flow, actual line temperature and pressure which are processed with the equations stored in the flow computer. A compressibility factor can be set to approach a real gas behavior. The reference conditions can be defined as desired (e.g. 15°C or 60°F and 1.013 bar).

The display shows the compensated flow rate, total, accumulated total and the actual line temperature and pressure. On-screen engineering units like Nm³ are easily configured from a comprehensive selection. -

The F120 single loop controller has been designed to offer outstanding control performance and provide a reliable solution for a wide variety of flow control applications. The single loop flow controller accepts most pulse inputs from flow meters and has a 4 - 20 mA output for controlling a valve or pump. The F120 is part of the Fluidwell process controller family and is the alternative for local control loops.

The F120 single loop controller has been designed to offer outstanding control performance and provide a reliable solution for a wide variety of flow control applications. The single loop flow controller accepts most pulse inputs from flow meters and has a 4 - 20 mA output for controlling a valve or pump. The F120 is part of the Fluidwell process controller family and is the alternative for local control loops. -

The batch controllers of the N-Series are much more advanced compared to our F-Series and D-Series batch controllers. The N-Series distinguishes itself from other batch controllers by its very easy to use numerical keypad. Selecting and entering multiple preset values with the easy to press keys is astonishingly simple. The display is designed for batch processes: at a glance, the operator is aware of the indicated switch points and the actual state of the process. For your convenience the preset and the actual value with their engineering units are displayed simultaneously.

The batch controllers of the N-Series are much more advanced compared to our F-Series and D-Series batch controllers. The N-Series distinguishes itself from other batch controllers by its very easy to use numerical keypad. Selecting and entering multiple preset values with the easy to press keys is astonishingly simple. The display is designed for batch processes: at a glance, the operator is aware of the indicated switch points and the actual state of the process. For your convenience the preset and the actual value with their engineering units are displayed simultaneously. -

The F040 is a straight forward temperature indicator with large 26mm (1") high digits. The measuring unit to be displayed below the temperature is simply selected through an alphanumeric configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user-friendly solution! The configuration of the Span, off-set and number of decimals is done through software functions, without any sensitive DIP-switches or trimmers.

The F040 is a straight forward temperature indicator with large 26mm (1") high digits. The measuring unit to be displayed below the temperature is simply selected through an alphanumeric configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user-friendly solution! The configuration of the Span, off-set and number of decimals is done through software functions, without any sensitive DIP-switches or trimmers. -

The F050 is a straight forward pressure indicator with large 26mm (1") high digits. The measuring unit to be displayed below the pressure is simply selected through an alphanumeric configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user-friendly solution!

The configuration of the Span, off-set and number of decimals is done through software functions, without any sensitive DIP-switches or trimmers.

The F050 is a straight forward pressure indicator with large 26mm (1") high digits. The measuring unit to be displayed below the pressure is simply selected through an alphanumeric configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user-friendly solution!

The configuration of the Span, off-set and number of decimals is done through software functions, without any sensitive DIP-switches or trimmers. -

The F073 is a versatile level indicator with continuous level monitoring feature. It offers the ability to set one low level and one high level alarm value. If desired, an ignore function can be set up to allow for an incorrect level for a certain period of time. The configuration of the Span, off-set and number of decimals is done through software functions, without any sensitive DIP-switches or trimmers. The display shows the actual level, height or percentage, alarm values, alarm messages and status. On-screen engineering units are easily configured from a comprehensive selection.

The F073 is a versatile level indicator with continuous level monitoring feature. It offers the ability to set one low level and one high level alarm value. If desired, an ignore function can be set up to allow for an incorrect level for a certain period of time. The configuration of the Span, off-set and number of decimals is done through software functions, without any sensitive DIP-switches or trimmers. The display shows the actual level, height or percentage, alarm values, alarm messages and status. On-screen engineering units are easily configured from a comprehensive selection. -

The D090 is a local, panel mount indicator to display the actual process value, range and loop current. The measuring unit to be displayed is simply selected through an alfa-numerical configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user friendly solution! The configuration of Span, offset and number of decimals is done through software functions, without any sensitive dip-switches or trimmers.

The D090 is a local, panel mount indicator to display the actual process value, range and loop current. The measuring unit to be displayed is simply selected through an alfa-numerical configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user friendly solution! The configuration of Span, offset and number of decimals is done through software functions, without any sensitive dip-switches or trimmers. -

The MS 2500 flanged sensor are well suited for all application and flow ranges. The MS2500 is available in the widest range of diameters.

Features;

• Accuracy to +/-0.2% of rate from 1 to 33 ft/sec.

• Nineteen sizes from 1" to 48" Pipe Diameters.

• Flow ranges from 2.37 to 179,400 GPM.

• Pressures to 5600 PSI.

• Volumetric flow rate measurement independent of fluid viscosity, density and temperature.

• No moving parts for zero maintenance.

• Bi-directional flow measurement.

• No pressure drop through sensor.

• Optional Integral ground electrode eliminates grounding rings with plastic piping systems.

• Minimal straight pipe run required.

• Every sensor is factory wet-calibrated.

The MS 2500 flanged sensor are well suited for all application and flow ranges. The MS2500 is available in the widest range of diameters.

Features;

• Accuracy to +/-0.2% of rate from 1 to 33 ft/sec.

• Nineteen sizes from 1" to 48" Pipe Diameters.

• Flow ranges from 2.37 to 179,400 GPM.

• Pressures to 5600 PSI.

• Volumetric flow rate measurement independent of fluid viscosity, density and temperature.

• No moving parts for zero maintenance.

• Bi-directional flow measurement.

• No pressure drop through sensor.

• Optional Integral ground electrode eliminates grounding rings with plastic piping systems.

• Minimal straight pipe run required.

• Every sensor is factory wet-calibrated. -

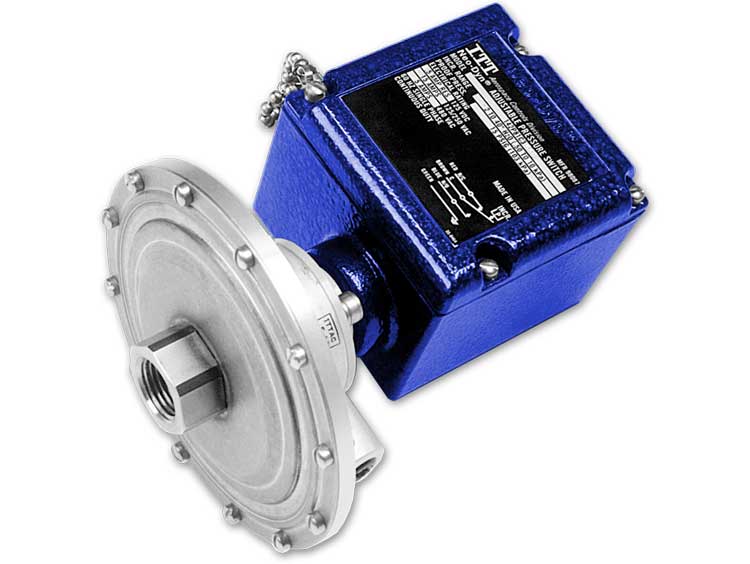

Series 100P (diaphragm sensor) for pneumatic and low impulse hydraulics up to 3000 psig system pressure

Versatile Nega-Rate® Belleville disc spring pressure switch for a wide range of applications.

Specifications

• Electrical: Snap action electrical switch recognized by Underwriters’ Laboratories, Inc. and CSA International

• Electrical Connection: 1/2 NPT female conduit connection with terminal block

• Pressure Connection:

o Wetted Material 1 1/4 NPT Female

o Wetted Material 4, 5, 7 and 9 1/2 NPT Female

• Temperature Range

o Ambient: -40°F to +180°F (-40°C to +82°C)

o Media: -40°F to +300°F (-40°C to +149°C)

• Media temperature limits change with O-Ring selection

• Adjustment: Concealed wrench flat adjustment with range scale

• Shipping Weight: Approximately 3 pounds

Series 100P (diaphragm sensor) for pneumatic and low impulse hydraulics up to 3000 psig system pressure

Versatile Nega-Rate® Belleville disc spring pressure switch for a wide range of applications.

Specifications

• Electrical: Snap action electrical switch recognized by Underwriters’ Laboratories, Inc. and CSA International

• Electrical Connection: 1/2 NPT female conduit connection with terminal block

• Pressure Connection:

o Wetted Material 1 1/4 NPT Female

o Wetted Material 4, 5, 7 and 9 1/2 NPT Female

• Temperature Range

o Ambient: -40°F to +180°F (-40°C to +82°C)

o Media: -40°F to +300°F (-40°C to +149°C)

• Media temperature limits change with O-Ring selection

• Adjustment: Concealed wrench flat adjustment with range scale

• Shipping Weight: Approximately 3 pounds -

142P8 NEMA 4X, 7, 9 & 13 Ultra Low Vacuum/Pressure Switch

Ultra-low pressure and vacuum to pressure crossover switch. Unique construction using efficient Nega-Rate® Belleville disc spring for stable set points and high proof pressure. Explosion proof enclosure and wide range of wetted materials makes this switch especially well-suited for hazardous or corrosive atmospheres.

Specifications

• Electrical: Snap action electrical switch listed by Underwriters’ Laboratories, Inc., FM Approval and CSA International

• Electrical Connection: 1/2 NPT male conduit connection with PVC insulated 18 AWG, 18” long leads

• Pressure Connection: 1/2 NPT Female

• Temperature Range*

o Ambient: -40°F to +180°F (-40°C to +82°C)

o Media: -50°F to +250°F (-46°C to +121°C)

• Adjustment: Concealed wrench flat adjustment with range scale

• Shipping Weight: Approximately 3.5 pounds

*Temperature limits change with O-Ring selection. See Electrical Assembly specification sheet for Temperature Class Ratings.

142P8 NEMA 4X, 7, 9 & 13 Ultra Low Vacuum/Pressure Switch

Ultra-low pressure and vacuum to pressure crossover switch. Unique construction using efficient Nega-Rate® Belleville disc spring for stable set points and high proof pressure. Explosion proof enclosure and wide range of wetted materials makes this switch especially well-suited for hazardous or corrosive atmospheres.

Specifications

• Electrical: Snap action electrical switch listed by Underwriters’ Laboratories, Inc., FM Approval and CSA International

• Electrical Connection: 1/2 NPT male conduit connection with PVC insulated 18 AWG, 18” long leads

• Pressure Connection: 1/2 NPT Female

• Temperature Range*

o Ambient: -40°F to +180°F (-40°C to +82°C)

o Media: -50°F to +250°F (-46°C to +121°C)

• Adjustment: Concealed wrench flat adjustment with range scale

• Shipping Weight: Approximately 3.5 pounds

*Temperature limits change with O-Ring selection. See Electrical Assembly specification sheet for Temperature Class Ratings. -

100T NEMA 4X, 7, 9 & 13 Temperature Switch/Internal Adjustment

Direct mount adjustable temperature switch for use in hazardous areas. Utilizes efficient Nega-Rate® Belleville spring mechanism and saturated vapor sensor for quick response and narrow deadband.

Specifications

• Electrical: Snap action electrical switch assembly listed by Underwriters’ Laboratories, Inc., FM Approval and CSA International

• Electrical Connection: 1/2 NPT male conduit connection with PVC insulated 18 AWG, 18" long leads

• Pressure Connection: 1/2 NPT Male; Direct mount

• Temperature Range:

o Ambient: -40°F to +180°F (-40°C to +82°C)

o See Electrical Assembly specification sheet for Temperature Class Ratings.

• System Pressure: 1500 psig maximum

• Proof Pressure: 2250 psig

• Adjustment: Concealed wrench flat adjustment with range scale

• Shipping Weight: Approximately 3 pounds

100T NEMA 4X, 7, 9 & 13 Temperature Switch/Internal Adjustment

Direct mount adjustable temperature switch for use in hazardous areas. Utilizes efficient Nega-Rate® Belleville spring mechanism and saturated vapor sensor for quick response and narrow deadband.

Specifications

• Electrical: Snap action electrical switch assembly listed by Underwriters’ Laboratories, Inc., FM Approval and CSA International

• Electrical Connection: 1/2 NPT male conduit connection with PVC insulated 18 AWG, 18" long leads

• Pressure Connection: 1/2 NPT Male; Direct mount

• Temperature Range:

o Ambient: -40°F to +180°F (-40°C to +82°C)

o See Electrical Assembly specification sheet for Temperature Class Ratings.

• System Pressure: 1500 psig maximum

• Proof Pressure: 2250 psig

• Adjustment: Concealed wrench flat adjustment with range scale

• Shipping Weight: Approximately 3 pounds -

162P NEMA 4X, 7, 9 & 13 Differential Pressure Switch

Adjustable high pressure differential switch. Rugged construction with efficient Nega-Rate® Belleville disc spring sensing mechanism. Maintains set point at high system pressure. Available in all stainless steel construction with hermetically sealed electrical assembly for corrosive atmospheres.

Specifications

• Electrical: Snap action electrical switch assembly listed by Underwriters’ Laboratories, Inc., FM Approval and CSA International

• Electrical Connection: 1/2 NPT male conduit connection with PVC insulated 18 AWG, 18" long leads

• Pressure Connections: 1/4 NPT Female

• Temperature Range*

o Ambient: -40°F to +180°F (-40°C to +82°C)

o Media: -40°F to +300°F (-40°C to +149°C)

• Adjustment: External 1/2" hex head

Note: Turn clockwise to increase set point; approximately 24 turns through range

• Shipping Weight:

o Aluminum: Approximately 3 lbs

o Stainless Steel: Approximately 7 lbs

*Temperature limits change with O-Ring selection. See Electrical Assembly specification sheet for Temperature Class Ratings.

162P NEMA 4X, 7, 9 & 13 Differential Pressure Switch

Adjustable high pressure differential switch. Rugged construction with efficient Nega-Rate® Belleville disc spring sensing mechanism. Maintains set point at high system pressure. Available in all stainless steel construction with hermetically sealed electrical assembly for corrosive atmospheres.

Specifications

• Electrical: Snap action electrical switch assembly listed by Underwriters’ Laboratories, Inc., FM Approval and CSA International

• Electrical Connection: 1/2 NPT male conduit connection with PVC insulated 18 AWG, 18" long leads

• Pressure Connections: 1/4 NPT Female

• Temperature Range*

o Ambient: -40°F to +180°F (-40°C to +82°C)

o Media: -40°F to +300°F (-40°C to +149°C)

• Adjustment: External 1/2" hex head

Note: Turn clockwise to increase set point; approximately 24 turns through range

• Shipping Weight:

o Aluminum: Approximately 3 lbs

o Stainless Steel: Approximately 7 lbs

*Temperature limits change with O-Ring selection. See Electrical Assembly specification sheet for Temperature Class Ratings. -

105P/105PP NEMA 1 & 2 Pressure Switch/Miniature Tamper Proof

All-purpose miniature tamper proof switch, extremely light weight and durable construction. Has efficient Nega-Rate® Belleville disc spring sensing mechanism. Small size improves vibration and shock resistance.

Specifications

• Deadband (Differential): The deadband can be selected anywhere from the minimum indicated to a maximum of 45% of the set point.

• Electrical Connection: PVC insulated 18 AWG leads 18" long

• Pressure Connection: 1/4 NPT Male

• Temperature Range*

o Ambient: -40°F to +180°F (-40°C to +82°C)

o Media: -40°F to +300°F (-40°C to +149°C)

• *Temperature limits change with O-Ring selection

• Shipping Weight: Approximately 3 ounces

105P/105PP NEMA 1 & 2 Pressure Switch/Miniature Tamper Proof

All-purpose miniature tamper proof switch, extremely light weight and durable construction. Has efficient Nega-Rate® Belleville disc spring sensing mechanism. Small size improves vibration and shock resistance.

Specifications

• Deadband (Differential): The deadband can be selected anywhere from the minimum indicated to a maximum of 45% of the set point.

• Electrical Connection: PVC insulated 18 AWG leads 18" long

• Pressure Connection: 1/4 NPT Male

• Temperature Range*

o Ambient: -40°F to +180°F (-40°C to +82°C)

o Media: -40°F to +300°F (-40°C to +149°C)

• *Temperature limits change with O-Ring selection

• Shipping Weight: Approximately 3 ounces -

Jogler Direct-Reading Level Gauges are the simplest, most reliable way to determine the level of liquid in a tank or vessel because they give you a direct view without compromising the integrity of your process system. Jogler level gauges are installed so that the liquid level in the transparent sight tube is always the same as the liquid level inside the tank or vessel.

Simple, reliable and maintenance-free Jogler level gauges are simple: the only components (not including mounting hardware) are the armored shield, the sight tubing and two self-sealing Super-Seal inserts. These products are maintenance-free because only the Teflon SuperSeal inserts and the borosilicate sight tubing are exposed to process fluids. Once the gauges are installed, they do not have to be removed and disassembled for inspection or cleaning. Standard shields are epoxy-coated carbon steel.

SuperSeal inserts for permanent, stress-free sealing All Jogler level gauges incorporate patented PTFE Teflon Super-Seal inserts, which seal on the outside diameter, not the ends, of the sight tube. Since Super-Seal inserts allow sight tube movement without leaking, stresses caused by differential expansion between the sight tube and the housing are eliminated. There are no elastomer seals or o-rings to inspect and replace: Super-Seal inserts last the life of the sight tubing

Jogler Direct-Reading Level Gauges are the simplest, most reliable way to determine the level of liquid in a tank or vessel because they give you a direct view without compromising the integrity of your process system. Jogler level gauges are installed so that the liquid level in the transparent sight tube is always the same as the liquid level inside the tank or vessel.

Simple, reliable and maintenance-free Jogler level gauges are simple: the only components (not including mounting hardware) are the armored shield, the sight tubing and two self-sealing Super-Seal inserts. These products are maintenance-free because only the Teflon SuperSeal inserts and the borosilicate sight tubing are exposed to process fluids. Once the gauges are installed, they do not have to be removed and disassembled for inspection or cleaning. Standard shields are epoxy-coated carbon steel.

SuperSeal inserts for permanent, stress-free sealing All Jogler level gauges incorporate patented PTFE Teflon Super-Seal inserts, which seal on the outside diameter, not the ends, of the sight tube. Since Super-Seal inserts allow sight tube movement without leaking, stresses caused by differential expansion between the sight tube and the housing are eliminated. There are no elastomer seals or o-rings to inspect and replace: Super-Seal inserts last the life of the sight tubing -

Model ILT-6000 (Patented) Magnetostrictive Level Transmitter

Direct Insertion for Tanks or Vessels

Jogler’s ILT-6000 series level transmitter is the latest in Magnetostrictive level sensing technology designed for direct tank insertion. The ILT-6000 contains a low provile waveguide that is inserted into an isolation well and float assembly. The waveguide sleeve isolates the internal waveguide from the process environment and protects it from excessive process conditions. This provides an additional safety barrier for the operator.

The major benefit is the transmitter and waveguide can be removed for field checking without interruption or exposure to the process environment. The isolation well and float are available in a variety of materials including 316SS , CPVC, Alloy 20, Titanium , Hastelloy , PP or PVDF.

Model ILT-6000 (Patented) Magnetostrictive Level Transmitter

Direct Insertion for Tanks or Vessels

Jogler’s ILT-6000 series level transmitter is the latest in Magnetostrictive level sensing technology designed for direct tank insertion. The ILT-6000 contains a low provile waveguide that is inserted into an isolation well and float assembly. The waveguide sleeve isolates the internal waveguide from the process environment and protects it from excessive process conditions. This provides an additional safety barrier for the operator.

The major benefit is the transmitter and waveguide can be removed for field checking without interruption or exposure to the process environment. The isolation well and float are available in a variety of materials including 316SS , CPVC, Alloy 20, Titanium , Hastelloy , PP or PVDF. -

Jogler Sight Flow Indicators have exclusive, patented features for maximum safety and zero maintenance.

Jogler Sight Flow Indicators are the simplest, most reliable way to observe liquid or solids flow without compromising the integrity of your piping system. All models are available in either armored styles for protection in exposed locations or lantern styles for 360-degree viewing. Jogler flow indicators are simple: the only components (not including mounting hardware) are the armored shield or lantern cage, the sight tubing and two self-sealing Super-Seal inserts

Jogler Sight Flow Indicators have exclusive, patented features for maximum safety and zero maintenance.

Jogler Sight Flow Indicators are the simplest, most reliable way to observe liquid or solids flow without compromising the integrity of your piping system. All models are available in either armored styles for protection in exposed locations or lantern styles for 360-degree viewing. Jogler flow indicators are simple: the only components (not including mounting hardware) are the armored shield or lantern cage, the sight tubing and two self-sealing Super-Seal inserts -

Jogler’s Specific Gravity Analyzers (SGAs) are a dependable and accurate method for measuring and sampling process liquid levels in virtually any application: – Acids – Caustics – Co-generation – Light Hydrocarbons – Beverages, etc.

Specific Gravity Analyzers are engineered for ease of installation and high reliability

SGAs present accurate visual verification of liquid density, can be cross-checked against temperature and are compatible with most requirements. Also, they require only small amounts of product for specific gravity measurement. SGAs are available in two standard configurations and two materials.

The hydrometer sleeve and sight tube are made of heavy wall borosilicate and the sight chamber is sealed with Teflon Super seals. The Jogler SGAs are equipped with 0.25” FNPT valves for flow control and sampling and the hydrometer is high-visibility and accurate. Installation and maintenance are engineered for simplicity and ease of use.

Jogler’s Specific Gravity Analyzers (SGAs) are a dependable and accurate method for measuring and sampling process liquid levels in virtually any application: – Acids – Caustics – Co-generation – Light Hydrocarbons – Beverages, etc.

Specific Gravity Analyzers are engineered for ease of installation and high reliability

SGAs present accurate visual verification of liquid density, can be cross-checked against temperature and are compatible with most requirements. Also, they require only small amounts of product for specific gravity measurement. SGAs are available in two standard configurations and two materials.

The hydrometer sleeve and sight tube are made of heavy wall borosilicate and the sight chamber is sealed with Teflon Super seals. The Jogler SGAs are equipped with 0.25” FNPT valves for flow control and sampling and the hydrometer is high-visibility and accurate. Installation and maintenance are engineered for simplicity and ease of use. -

Micro-DCI 53MC5000 Process Control Station

High performance multi-loop controller for any process application, from simple PID to the most complex control strategy—that’s the hallmark of the 53MC5000 controller. As the foundation of the Micro-DCI product family, it’s designed for real-time control, supervision, and process management.Integration into plantwide systems can be achieved with the E-Port Ethernet Gateway, allowing you to connect 53MC5000 Controllers to MicroMod and third-party HMI software.The 53MC5000 controller forms the basis of MicroMod’s WaterPAK series of pre-engineered packages.Features:

- A choice of one, two, or four-loop versions with expandable I/O up tp 16 DI/DO for advanced control functionality

- Easier operation of any process, with a high-visibility graphic display accommodating standard or custom operating screens

- Superior versatility—a library of standard configurations, easily modified from the front panel, can be expanded to accommodate custom control strategies

- PLC/Printer option for direct communication with most popular PLCs and serial printers

- Micro-Tools configuration software — allowing creation of user programs in a high-level language for batch and advanced control

- Standard serial communications and optional high-speed, peer-to-peer redundant networks for seamless integration into virtually any plant-monitoring system—including MicroMod’s Micro-PWC software

-

MicroMod’s SteamPAK series of pre-engineered boiler-control packages are available for steam and hot water, gas and/or oil, and single or dual fuel boilers. These ready-to-install solutions offer pre-programmed controllers and application-specific installation, startup, and operation manuals. And, now, our “plug-and-play” performance has been further enhanced for even greater simplicity and flexibility

MicroMod’s SteamPAK series of pre-engineered boiler-control packages are available for steam and hot water, gas and/or oil, and single or dual fuel boilers. These ready-to-install solutions offer pre-programmed controllers and application-specific installation, startup, and operation manuals. And, now, our “plug-and-play” performance has been further enhanced for even greater simplicity and flexibility -

V100 MultiPurpose Industrial Variable Speed Drives. The V100 is available in 0.55 to 90 kW (0.75 - 125 HP) 230V and 1.1-160 kW (1.5 - 200 HP) 500V. The wall-mountable drive modules are easy to install and operate, with IP21/UL Type1 provided as standard. Options include IP54/UL Type12 and flange mounting. Standard features include built-in I/O with 3 option slots, integrated RS-485 and Ethernet-based communications, conformal coating and robust motor control features for reliability.

V100 MultiPurpose Industrial Variable Speed Drives. The V100 is available in 0.55 to 90 kW (0.75 - 125 HP) 230V and 1.1-160 kW (1.5 - 200 HP) 500V. The wall-mountable drive modules are easy to install and operate, with IP21/UL Type1 provided as standard. Options include IP54/UL Type12 and flange mounting. Standard features include built-in I/O with 3 option slots, integrated RS-485 and Ethernet-based communications, conformal coating and robust motor control features for reliability. -

MicroTorque’s adaptive control algorithms and electric braking feature allow it to quickly hit the set point with out overshoot, increasing accuracy and reducing hunting which leads to better process control, less wear and less maintenance. The patented control circuitry allows our actuator to bridge the gap between the larger high priced actuators on the market and less accurate economy models. The Duty Cycle Protection feature prevents thermal overload while providing excellent torque and response time.

MicroTorque’s adaptive control algorithms and electric braking feature allow it to quickly hit the set point with out overshoot, increasing accuracy and reducing hunting which leads to better process control, less wear and less maintenance. The patented control circuitry allows our actuator to bridge the gap between the larger high priced actuators on the market and less accurate economy models. The Duty Cycle Protection feature prevents thermal overload while providing excellent torque and response time. -

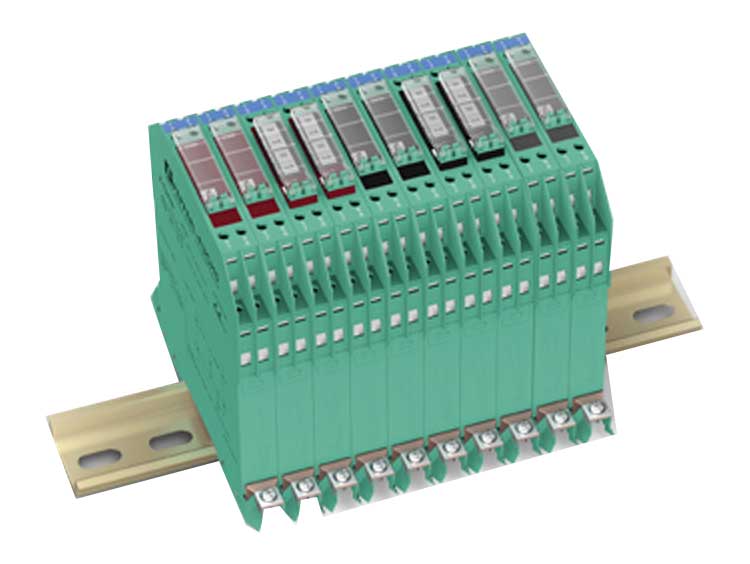

The K-system comprises signal conditioners for signal transfer between control system and safe area as well as isolated barriers for communication with field devices in hazardous areas. They are preferred for these kinds of mixed applications. Wide range of isolated barriers and signal conditioners for mixed applications

Modules for universal power supply

Reduced wiring by Power Rail

Removable terminals

Many modules with marine approvals and SIL assessment

The K-system comprises signal conditioners for signal transfer between control system and safe area as well as isolated barriers for communication with field devices in hazardous areas. They are preferred for these kinds of mixed applications. Wide range of isolated barriers and signal conditioners for mixed applications

Modules for universal power supply

Reduced wiring by Power Rail

Removable terminals

Many modules with marine approvals and SIL assessment