The BULLET WirelessHART Adapter enables new and existing wired smart HART fi eld devices, non-smart analog fi eld devices and remote HART I/O from any supplier to communicate with host applications using WirelessHART technology.

The BULLET WirelessHART Adapter enables new and existing wired smart HART fi eld devices, non-smart analog fi eld devices and remote HART I/O from any supplier to communicate with host applications using WirelessHART technology.

-

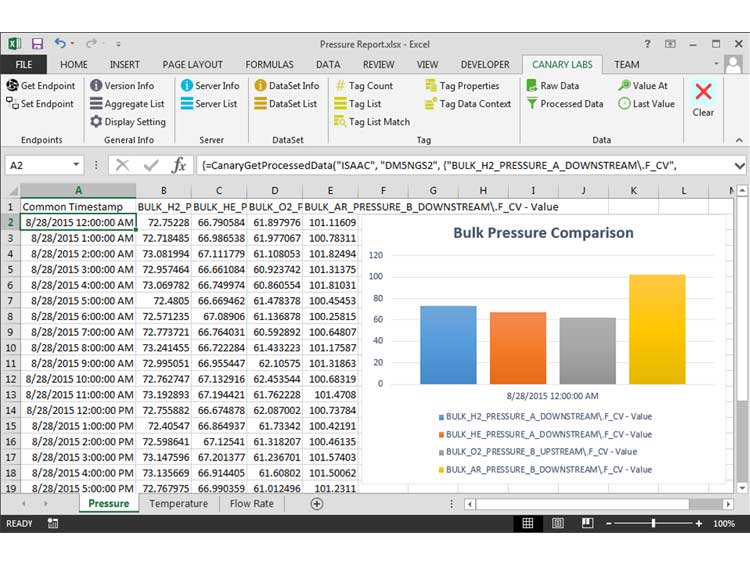

Canary Lab's Reports

Pull your data into Excel using our Excel Add-In. You can retrieve raw or processed data that can be used to generate reports, analyze data, and make business decisions.Features:

- Ribbon ... Use buttons in the ribbon to open dialogs that will build or modify your calls to our Historian

- Connection ... Connect to remote Historians, or connect using credentials if security is turned on

- Raw Data ... Retrieve raw data from the historian. Choose display options for the data

- Processed Data ... Retrieve processed data from the historian. There are a number of aggregates that can be used

-

Canary Lab's Alarms

Use TopView® to monitor your process and automation data. Generate audible alarms, send e-mail notification, SMS/text notification, voice notification and SNMP traps.Features:

- Monitor ... Access to values, alarms, and alarm history

- Notify ... Robust notification engine supporting a wide variety of devices

- Analyze ... Built-in alarm reports can be scheduled and emailed

- Scalable ... Monitor 100 tags or 100,000 tags

-

Canary Lab's Axiom

Maximize your data historian by analyzing process data in the most advanced trending software available. Innovative, easy to use, and feature rich, Axiom will transform your ability to trend process data and gather knowledge from your data historian.Features:

- Ad Hoc Trends ... Add or remove trends quickly using our browse dialog to pick which trends you want to view

- Calculated Trends ... Use standard calculator operations to add a calculated trend based on one or more trends

- Link Scales/Bands ... Link scales of two or more trends so their data is displayed between the same ranges. Link bands to overlap trends

- Limit Lines ... Set limit lines for a trend. Use limits to draw a horizontal line across the screen, to fill in space between a limit and the trend, or to change the color of the trend

- Value Cursor ... Use your cursor to hover over the chart and view the values as you move your mouse

- Zoom ... Quickly zoom in on a range of data to examine it more closely

-

Canary Lab's Data Historian

Our process data historian writes and retrieves historical data with industry leading speed. It can store millions of tags accurately and reliably without any data management.Features:

- Scalable ... capable of storing data for millions of tags

- Fast Read/Write ... Writes up to 4,000,000 points per second

- Data Handling ... Handles sub second data down to 100 nanoseconds

- Data Integrity ... Lossless compression algorithms are used

- Data Accessibility ... OPC, HDA, and ODBC compatible. We also have an API

- Custom Views ... Custom hierarchical models of the data can be created

- Easy Administration ... Easy data management without a database administrator

- Limitless Storage ... No need to purge or optimize the database

- Tag Security ... Tag security so you have complete control of data access

-

Substantially reduce the cost of transmitting process signals with Moore Industries’ unique problem solver, the CCS® Cable Concentrator System®. The industryfirst CCS provides money-saving solutions for both monitoring and control applications. Data Acquisition—The CCS collects any combination of up to 496 analog and/or digital signals from dispersed devices (transmitters, transducers, contact closures, etc.). It digitizes and concentrates the signals on to an RS-485 communication link, and sends the data miles between locations. Control—With the CCS, you can transmit control signals long distances on a single data link to valves, pumps, motors, and other devices that require precise on/off or proportional control.

Substantially reduce the cost of transmitting process signals with Moore Industries’ unique problem solver, the CCS® Cable Concentrator System®. The industryfirst CCS provides money-saving solutions for both monitoring and control applications. Data Acquisition—The CCS collects any combination of up to 496 analog and/or digital signals from dispersed devices (transmitters, transducers, contact closures, etc.). It digitizes and concentrates the signals on to an RS-485 communication link, and sends the data miles between locations. Control—With the CCS, you can transmit control signals long distances on a single data link to valves, pumps, motors, and other devices that require precise on/off or proportional control. -

Circulation Heaters Type Ex. Designed for forced flow or natural flow applications. Standard designs ranging from 0.6 to 672kW… higher kWratings are also available.Optional features include built in high limits and thermostats, stainless steel wetted parts. moisture resistant or explosion-proof housings. CRN registered vessels for Canada. Authorized to bear the U and N stamps, depending on ASME code classification (Section VIII or III)

Circulation Heaters Type Ex. Designed for forced flow or natural flow applications. Standard designs ranging from 0.6 to 672kW… higher kWratings are also available.Optional features include built in high limits and thermostats, stainless steel wetted parts. moisture resistant or explosion-proof housings. CRN registered vessels for Canada. Authorized to bear the U and N stamps, depending on ASME code classification (Section VIII or III) -

eltherms’ Clean Laser Seal technology takes Mineral Insulated (MI) Trace Heater assemblies to the next level.Manufactured and assembled entirely from high quality stainless steel or Alloy 825, eltherm‘s revolutionary Clean Laser Seal Technology (CLS) guarantees performance and reliability in all industrial operations.CLS offers today‘s best possible protection from stress corrosion cracking in applications in which aggressive chemicals may be present.Stainless steel and Alloy 825 is the material of choice for temperature process control and ideally suited for freeze protection or viscosity control applications subject to periodic high temperature exposure.Our proprietary clean laser sealing process provides a 100% stable, homogeneous system, resulting in a reliable and maintenance-free assembly.

eltherms’ Clean Laser Seal technology takes Mineral Insulated (MI) Trace Heater assemblies to the next level.Manufactured and assembled entirely from high quality stainless steel or Alloy 825, eltherm‘s revolutionary Clean Laser Seal Technology (CLS) guarantees performance and reliability in all industrial operations.CLS offers today‘s best possible protection from stress corrosion cracking in applications in which aggressive chemicals may be present.Stainless steel and Alloy 825 is the material of choice for temperature process control and ideally suited for freeze protection or viscosity control applications subject to periodic high temperature exposure.Our proprietary clean laser sealing process provides a 100% stable, homogeneous system, resulting in a reliable and maintenance-free assembly.Features:

- Factory terminated laser sealed technology

- All components in high quality stainless steel or Alloy 825

- High temperature resistance

- High chemical resistance

- High power output

- Flexible single or twin conductor configurations

- Moisture proof, may be immersed in fluid

Applications in Detail:

- Freeze/viscosity protection in industrial processes

- Process temperature maintain

- Vendor skids and process modules (cookie cutter custom units)

- Heat tracing of instrumentation and sample stations

- Vessel and trim tracing

- High temperature exposure

- Aseptic manufacturing conditions

- High watt density requirements

- Vacuum Processes

- Heat Treating Processes

- Heat tracing on instrumentation

-

The CPMS Cathodic Protection Monitoring System monitors above and below ground impressed current cathodic protection systems to ensure that proper corrosion protection is in place and operating at the right levels. Part of Moore Industries’ NET Concentrator System® family of intelligent distributed I/O, the CPMS monitors the critical current and voltage levels of one or two transformer rectifi ers used in cathodic protection systems.

The CPMS Cathodic Protection Monitoring System monitors above and below ground impressed current cathodic protection systems to ensure that proper corrosion protection is in place and operating at the right levels. Part of Moore Industries’ NET Concentrator System® family of intelligent distributed I/O, the CPMS monitors the critical current and voltage levels of one or two transformer rectifi ers used in cathodic protection systems. -

Compact flow meter which integrates in a the same body the sensor and the converter

Sensor body in galvanized zinc steel PTFE coated with SS electrodes.

Available sizes DN10 – DN 15 and DN20

Threaded process connections

Configuration via PC

Pulse and Analogue outputs

Capability to measure the process temperature

Suitable for flow control where flow might need to be controlled according to the temperature such as cooling systems on tooling machines, washing systems etc.

Please refer to the enclosed documentation for further information.

Compact flow meter which integrates in a the same body the sensor and the converter

Sensor body in galvanized zinc steel PTFE coated with SS electrodes.

Available sizes DN10 – DN 15 and DN20

Threaded process connections

Configuration via PC

Pulse and Analogue outputs

Capability to measure the process temperature

Suitable for flow control where flow might need to be controlled according to the temperature such as cooling systems on tooling machines, washing systems etc.

Please refer to the enclosed documentation for further information. -

New low-cost, compact version of our ISOMAG electromagnetic flow meters. Designed to be easily incorporated into equipment or machinery.

Features:

- Small electromagnetic flow meter with integrated display

- Suitable for flow measurement in liquids with a minimum conductivity of 20 µS/cm

- Measuring accuracy ± 1% of reading

- Housing in Noryl reinforced with 30% fiberglass

- Protection rating NEMA 6 (IP 67)

- Max liquid temperature 185°F

- Power supply 18-30 VDC

- Digital and analog outputs can be configured via PC, using dedicated MCP software

Applications:

- Replacement of mechanical meters

- Solvent Dispensers

- Flow Control for water-soluble coolant

- Sampling systems

- Dosing of additives in concrete

- Water distribution for industrial cooking, washing machines

- Control of consumption

- Wood treatment

- Control in cooling systems for welding, laser machines, robots or metal manufacturing

- Machine Tools

-

The D016 is a loca,l panel mount indicator with linearization to display the actual flow rate, total and accumulated total. The total can be reset to zero by pressing the CLEAR button twice. The eleven digit accumulated total however can not be reset to zero. In addition to the average K-Factor or Span, eight linearization points can be entered with there frequencies or values. The unit will interpolate between these points greatly enhancing accuracy in any flowrange. Even for very low frequency applications is catered for. This linearization affects all displayed information as well as the pulse output.

The D016 is a loca,l panel mount indicator with linearization to display the actual flow rate, total and accumulated total. The total can be reset to zero by pressing the CLEAR button twice. The eleven digit accumulated total however can not be reset to zero. In addition to the average K-Factor or Span, eight linearization points can be entered with there frequencies or values. The unit will interpolate between these points greatly enhancing accuracy in any flowrange. Even for very low frequency applications is catered for. This linearization affects all displayed information as well as the pulse output. -

he D030 is a straight forward but basic, panel mount batch controller. The operator can enter a batch quantity easily or execute repeating batches. During the batch, the preset value is displayed as well as the batched (or remaining) quantity and the units of measurement. The automatic self-learning overrun correction will ensure an accurate result each batch again.

he D030 is a straight forward but basic, panel mount batch controller. The operator can enter a batch quantity easily or execute repeating batches. During the batch, the preset value is displayed as well as the batched (or remaining) quantity and the units of measurement. The automatic self-learning overrun correction will ensure an accurate result each batch again. -

D74 2-PIECE INDUSTRIAL SEAL

DESCRIPTION & FEATURES

- Two piece construction and designed to withstand even the most severe process applications

- “Continuous use” seals – backing plate will prevent diaphragm from rupturing if pressure sensing instrument fails. Pressure will be held until instrument is replaced

- Diaphragm is separable for servicing and is available with a 1/4” NPT flushing connection for removing any material which may clog the process connection

- Standard diaphragm is constructed of AISI 316 stainless steel and welded to the upper chamber of the seal

- ASME B40.100 compliant

- 5 year warranty

APPLICATIONS

Where the media is low in pressure and the process fluid is corrosive or viscous and would clog instrument internals/solidify within the pressure gauge, switch or transmitter -

The D053 is a versatile, panel mount pressure indicator with continuous pressure monitoring feature. It offers the facility to set one low pressure and one high pressure alarm value. If desired, an ignore function can be set up to allow for an incorrect pressure for a certain period of time.

Advantages

Unique, robust IP66, IP67 (Type4X) panel mount front enclosure made of die cast aluminum, allowing even big jets of water and total immersion.

Programming can be done by your own crew with the exact same, plain and sensible menu-driven structure like the F-Series, saving cost and irritation. Know one, know them all!

The D053 is a versatile, panel mount pressure indicator with continuous pressure monitoring feature. It offers the facility to set one low pressure and one high pressure alarm value. If desired, an ignore function can be set up to allow for an incorrect pressure for a certain period of time.

Advantages

Unique, robust IP66, IP67 (Type4X) panel mount front enclosure made of die cast aluminum, allowing even big jets of water and total immersion.

Programming can be done by your own crew with the exact same, plain and sensible menu-driven structure like the F-Series, saving cost and irritation. Know one, know them all! -

The D040 is a straight forward, panel mount temperature indicator. The measuring unit to be displayed is simply selected through an alfa-numerical configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user friendly solution! The configuration of the Span, off-set and number of decimals is done through software functions, without any sensitive dip-switches or trimmers.

Advantages

Unique, robust IP66, IP67 (Type4X) panel mount front enclosure made of die cast aluminum, allowing even big jets of water and total immersion.

Programming can be done by your own crew with the exact same, plain and sensible menu-driven structure like the F-Series, saving cost and irritation. Know one, know them all!

The D040 is a straight forward, panel mount temperature indicator. The measuring unit to be displayed is simply selected through an alfa-numerical configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user friendly solution! The configuration of the Span, off-set and number of decimals is done through software functions, without any sensitive dip-switches or trimmers.

Advantages

Unique, robust IP66, IP67 (Type4X) panel mount front enclosure made of die cast aluminum, allowing even big jets of water and total immersion.

Programming can be done by your own crew with the exact same, plain and sensible menu-driven structure like the F-Series, saving cost and irritation. Know one, know them all! -

The D016 is a local panel mount indicator / transmitter with linearization to display the actual flow rate, total and accumulated total. The total can be reset to zero by pressing the CLEAR button twice. The eleven digit accumulated total however cannot be reset to zero. In addition to the average K-Factor or Span, eight linearization points can be entered with their frequencies or values. The unit will interpolate between these points greatly enhancing accuracy in any flow range. Even for very low frequency applications is catered for. This linearization affects all displayed information as well as the pulse output.

The D016 is a local panel mount indicator / transmitter with linearization to display the actual flow rate, total and accumulated total. The total can be reset to zero by pressing the CLEAR button twice. The eleven digit accumulated total however cannot be reset to zero. In addition to the average K-Factor or Span, eight linearization points can be entered with their frequencies or values. The unit will interpolate between these points greatly enhancing accuracy in any flow range. Even for very low frequency applications is catered for. This linearization affects all displayed information as well as the pulse output. -

The D013 is a versatile, panel mount flow rate indicator and totalizer with continuous flow rate monitoring feature. It offers the facility to set one low flow rate and one high flow rate alarm value. If desired, a delay function can be set up to allow for an incorrect flow rate for a certain period of time.

The D013 is a versatile, panel mount flow rate indicator and totalizer with continuous flow rate monitoring feature. It offers the facility to set one low flow rate and one high flow rate alarm value. If desired, a delay function can be set up to allow for an incorrect flow rate for a certain period of time. -

The D090 is a local, panel mount indicator to display the actual process value, range and loop current. The measuring unit to be displayed is simply selected through an alfa-numerical configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user friendly solution! The configuration of Span, offset and number of decimals is done through software functions, without any sensitive dip-switches or trimmers.

The D090 is a local, panel mount indicator to display the actual process value, range and loop current. The measuring unit to be displayed is simply selected through an alfa-numerical configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user friendly solution! The configuration of Span, offset and number of decimals is done through software functions, without any sensitive dip-switches or trimmers. -

The D074 is a basic, panel mount level / pump controller that works with a pre-set value and two switch points to control a pump or valve. The low and high level switch points are entered as a percentage of the pre-set value to switch the device on / off. For pump control applications, the function can be inverted to empty a well. A stable level within a hysteresis around the pre-set value is the result.

The D074 is a basic, panel mount level / pump controller that works with a pre-set value and two switch points to control a pump or valve. The low and high level switch points are entered as a percentage of the pre-set value to switch the device on / off. For pump control applications, the function can be inverted to empty a well. A stable level within a hysteresis around the pre-set value is the result.

-

The D074 is a basic, panel mount level / pump controller that works with a pre-set value and two switch points to control a pump or valve. The low and high level switch points are entered as a percentage of the pre-set value to switch the device on / off. For pump control applications, the function can be inverted to empty a well. A stable level within a hysteresis around the pre-set value is the result.

The D074 is a basic, panel mount level / pump controller that works with a pre-set value and two switch points to control a pump or valve. The low and high level switch points are entered as a percentage of the pre-set value to switch the device on / off. For pump control applications, the function can be inverted to empty a well. A stable level within a hysteresis around the pre-set value is the result.

-

CX Domestic Immersion Heaters were developed as high quality replacements for the most commonly used heater types. The CXC is available in a range of styles, including 2.5" (64 mm) square flange with tinned copper sheath, 1" (25 mm) tapered brass plug with copper sheath, 1" (25 mm) non-tapered brass plug with copper sheath and round flange with zinc plated copper sheath. The CXI is available with a 2.5" (64 mm) square flange with Incoloy® sheath. Elements are epoxy-coated to protect the heater from moisture and other contaminants that can lead to premature element failure.

CX Domestic Immersion Heaters were developed as high quality replacements for the most commonly used heater types. The CXC is available in a range of styles, including 2.5" (64 mm) square flange with tinned copper sheath, 1" (25 mm) tapered brass plug with copper sheath, 1" (25 mm) non-tapered brass plug with copper sheath and round flange with zinc plated copper sheath. The CXI is available with a 2.5" (64 mm) square flange with Incoloy® sheath. Elements are epoxy-coated to protect the heater from moisture and other contaminants that can lead to premature element failure. -

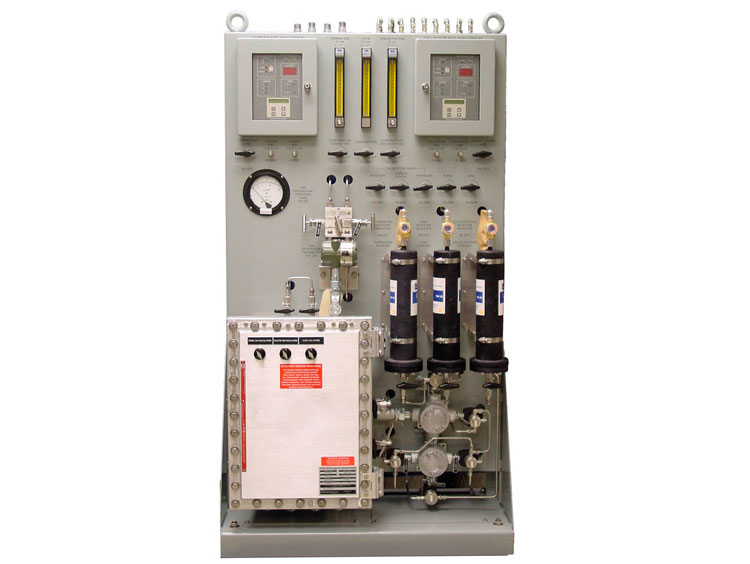

Environment One's Dual Hydrogen Control Panel (DHCP) was designed specifically for monitoring GE's scavenging seal oil generators. The DHCP contains two independent analyzers that monitor the turbine-end seal drain enlargement, collector-end seal oil drain enlargement with both valving for manual or DCS operation for checking casing purity of the generator.

Environment One's Dual Hydrogen Control Panel (DHCP) was designed specifically for monitoring GE's scavenging seal oil generators. The DHCP contains two independent analyzers that monitor the turbine-end seal drain enlargement, collector-end seal oil drain enlargement with both valving for manual or DCS operation for checking casing purity of the generator. -

The E115 has been developed for applications where the direction of flow is an issue. Applications can be found by loading and unloading of ships where one bi-directional flowmeter is used. Another application is the correction of back-flow due to shocks in a pipeline caused by piston pumps or valve behavior. It is required to offer two pulse signals from the flowmeter which are 90° or 270° degrees out of phase.The E-series distinguishes itself by its quality and functionality driven European design and manufacturing. It is more than fulfilling the rules for explosion proof design, it is about safety during the daily operation. Often, the environment is much tougher than the explosion proof requirements demand. Thus dangerous conditions may be experienced due to a broken enclosure or a poorly made flame path. Ruggedness and reliability is where Fluidwell stands for and it is now available in a comprehensive well designed and purpose driven explosion proof flow rate indicator / totalizer.

The E115 has been developed for applications where the direction of flow is an issue. Applications can be found by loading and unloading of ships where one bi-directional flowmeter is used. Another application is the correction of back-flow due to shocks in a pipeline caused by piston pumps or valve behavior. It is required to offer two pulse signals from the flowmeter which are 90° or 270° degrees out of phase.The E-series distinguishes itself by its quality and functionality driven European design and manufacturing. It is more than fulfilling the rules for explosion proof design, it is about safety during the daily operation. Often, the environment is much tougher than the explosion proof requirements demand. Thus dangerous conditions may be experienced due to a broken enclosure or a poorly made flame path. Ruggedness and reliability is where Fluidwell stands for and it is now available in a comprehensive well designed and purpose driven explosion proof flow rate indicator / totalizer.

Features:

- Explosion proof according ATEX, IECEx, FM and CSA C-US.

- Aluminum or high grade stainless steel Ex d enclosure.

- Easy installation with the spacious chamber and plug & play connectors.

- Cost saving with an easy to install, 1” NPT thread for direct flowmeter mounting.

- Detects flow direction with quadrature signal inputs.

- Key information at a glance as the display shows forward & reverse flow rate, forward & reverse total, accumulated total count up and count down ref. flow direction, measuring units and a flow rate indicating speedometer.

- Easy K-factor and engineering unit configuration for volumetric or mass. Learn more with this interactive tutorial.

- 7 digit flow rate / total and 11 digit accumulated total.

- Bright LED backlight.

- Easy configurable via PC with free downloadable remote configuration tool and special communication cable (ACE01/02/06/07).

- Auto backup of settings and running totals.

- Ambient temperature: -40°C to +70°C (-40°F to 158°F).

- Various accessories are available for this product.

Hazardous area information:

- The E-Series are ATEX, IECEx, FM and CSA C-US certified for an ambient temperature range of -40°C to +70°C (-40°F to +158°F).

-

The ECA DIN-style Alarm features a solid metal housing that stands up to the continual rigors of process control and factory automation applications. Rugged and reliable, the 4-wire (line-powered) ECA is the low-cost solution when alarm trip outputs are needed to indicate high or low process conditions. Available models accept current and voltage input from field transmitters, transducers, and other process instruments. When the input falls outside of a pre-set limit (user configurable), the ECA provides contact closure outputs ideal for indicating a high and/or low condition via a bell, buzzer, light or other annunciating device.

The ECA DIN-style Alarm features a solid metal housing that stands up to the continual rigors of process control and factory automation applications. Rugged and reliable, the 4-wire (line-powered) ECA is the low-cost solution when alarm trip outputs are needed to indicate high or low process conditions. Available models accept current and voltage input from field transmitters, transducers, and other process instruments. When the input falls outside of a pre-set limit (user configurable), the ECA provides contact closure outputs ideal for indicating a high and/or low condition via a bell, buzzer, light or other annunciating device. -

ECT DIN-style signal isolators, converters, repeaters, boosters and splitters feature solid metal housings that stand up to the continuous, daily rigors of process control and factory automation applications. Rugged and reliable, the ECT is available in 2-wire (loop) and 4-wire (line/mains) powered models. The complete family delivers economical solutions for an expansive range of signal interface applications.

Download Data Sheet

ECT DIN-style signal isolators, converters, repeaters, boosters and splitters feature solid metal housings that stand up to the continuous, daily rigors of process control and factory automation applications. Rugged and reliable, the ECT is available in 2-wire (loop) and 4-wire (line/mains) powered models. The complete family delivers economical solutions for an expansive range of signal interface applications.

Download Data Sheet -

The Pepperl+Fuchs Enviro-Line purging units is an enclosure pressurization system for non hazardous areas that operates on a supply of compressed instrument air or inert gas. It regulates and monitors the pressure within the sealed enclosure at a constant pressure in order to prevent the accumulation of damaging and caustic gases and dusts.

The elimination of these gases and dusts extends the life of expensive electrical equipment and instrumentation placed within the Enviro-Line purging unit.Due to higher pressures inside the electrical enclosure, corrosive environments remain outside. The system maintains a constant 0.5" water pressure inside the enclosure for protection against gas and/or dust.

The Pepperl+Fuchs Enviro-Line purging units is an enclosure pressurization system for non hazardous areas that operates on a supply of compressed instrument air or inert gas. It regulates and monitors the pressure within the sealed enclosure at a constant pressure in order to prevent the accumulation of damaging and caustic gases and dusts.

The elimination of these gases and dusts extends the life of expensive electrical equipment and instrumentation placed within the Enviro-Line purging unit.Due to higher pressures inside the electrical enclosure, corrosive environments remain outside. The system maintains a constant 0.5" water pressure inside the enclosure for protection against gas and/or dust.- Environmental purge for nonhazardous areas

- Built in ISO 9001 registered manufacturing facilities

- Complete package for enclosures up to 7.2 m3 (250 ft3)

-

The E018 is one of the top models in our range of explosion proof flow computers. In addition to the average K-Factor, 16 linearization points can be entered. The unit will interpolate between these points greatly enhancing accuracy in any flow range. Moreover, a continuous flow rate monitoring feature is available with high and low flow rate alarm values and four alarm outputs.

The E018 is one of the top models in our range of explosion proof flow computers. In addition to the average K-Factor, 16 linearization points can be entered. The unit will interpolate between these points greatly enhancing accuracy in any flow range. Moreover, a continuous flow rate monitoring feature is available with high and low flow rate alarm values and four alarm outputs. -

The F490 is a versatile, loop powered Multi Purpose Indicator which displays the actual process value, range and loop current. Besides the focus on level, temperature and pressure applications, the F490 can also work with other measuring units, such as %, mA, RPM and more. Therefore, the F490 is a versatile indicator that suits many applications.

At the F490, the input circuit is separated from the backlight circuit. It is designed in such way that it does not influence the intrinsically safe circuit to which it is connected.

The F490 accepts 4 - 20mA input signals from a wide range of process instruments, including flow (linear or square root), level, pressure and temperature transmitters. All these process parameters can be displayed in their own engineering units. Thanks to its ruggedness, the F490 withstands extreme weather conditions such as rain, snow, sun, sandy deserts, salty atmospheres and temperatures between -40°C/-40°F and +80°C/+178°F without the need for expensive protective cabinets. Moreover, all products in the F-series are robust by design: even a truck can stand on them.

The F490 is a versatile, loop powered Multi Purpose Indicator which displays the actual process value, range and loop current. Besides the focus on level, temperature and pressure applications, the F490 can also work with other measuring units, such as %, mA, RPM and more. Therefore, the F490 is a versatile indicator that suits many applications.

At the F490, the input circuit is separated from the backlight circuit. It is designed in such way that it does not influence the intrinsically safe circuit to which it is connected.

The F490 accepts 4 - 20mA input signals from a wide range of process instruments, including flow (linear or square root), level, pressure and temperature transmitters. All these process parameters can be displayed in their own engineering units. Thanks to its ruggedness, the F490 withstands extreme weather conditions such as rain, snow, sun, sandy deserts, salty atmospheres and temperatures between -40°C/-40°F and +80°C/+178°F without the need for expensive protective cabinets. Moreover, all products in the F-series are robust by design: even a truck can stand on them.

Hazardous area information

The F490 is certified according ATEX, IECEx and CSA for use in Intrinsically Safe applications with an ambient temperature of -40°C to +70°C (-40°F to +158°F). ATEX markings: Gas: II 1 G Ex ia IIC T4 Ga Dust: II 1 D Ex ia IIIC T100°C Da IECEx markings: Gas: Ex ia IIC T4 Ga Dust: Ex ia IIIC T100°C Da CSA c-us markings: IS Class I/II/III, Division 1, Groups A to G. Ex ia IIC / Class 1 Zone 0 AEx ia IIC T4.