Jogler Sight Flow Indicators have exclusive, patented features for maximum safety and zero maintenance.

Jogler Sight Flow Indicators are the simplest, most reliable way to observe liquid or solids flow without compromising the integrity of your piping system. All models are available in either armored styles for protection in exposed locations or lantern styles for 360-degree viewing. Jogler flow indicators are simple: the only components (not including mounting hardware) are the armored shield or lantern cage, the sight tubing and two self-sealing Super-Seal inserts

Jogler Sight Flow Indicators have exclusive, patented features for maximum safety and zero maintenance.

Jogler Sight Flow Indicators are the simplest, most reliable way to observe liquid or solids flow without compromising the integrity of your piping system. All models are available in either armored styles for protection in exposed locations or lantern styles for 360-degree viewing. Jogler flow indicators are simple: the only components (not including mounting hardware) are the armored shield or lantern cage, the sight tubing and two self-sealing Super-Seal inserts -

Jogler Sight Flow Indicators have exclusive, patented features for maximum safety and zero maintenance.

Jogler Sight Flow Indicators are the simplest, most reliable way to observe liquid or solids flow without compromising the integrity of your piping system. All models are available in either armored styles for protection in exposed locations or lantern styles for 360-degree viewing. Jogler flow indicators are simple: the only components (not including mounting hardware) are the armored shield or lantern cage, the sight tubing and two self-sealing Super-Seal inserts

Jogler Sight Flow Indicators have exclusive, patented features for maximum safety and zero maintenance.

Jogler Sight Flow Indicators are the simplest, most reliable way to observe liquid or solids flow without compromising the integrity of your piping system. All models are available in either armored styles for protection in exposed locations or lantern styles for 360-degree viewing. Jogler flow indicators are simple: the only components (not including mounting hardware) are the armored shield or lantern cage, the sight tubing and two self-sealing Super-Seal inserts -

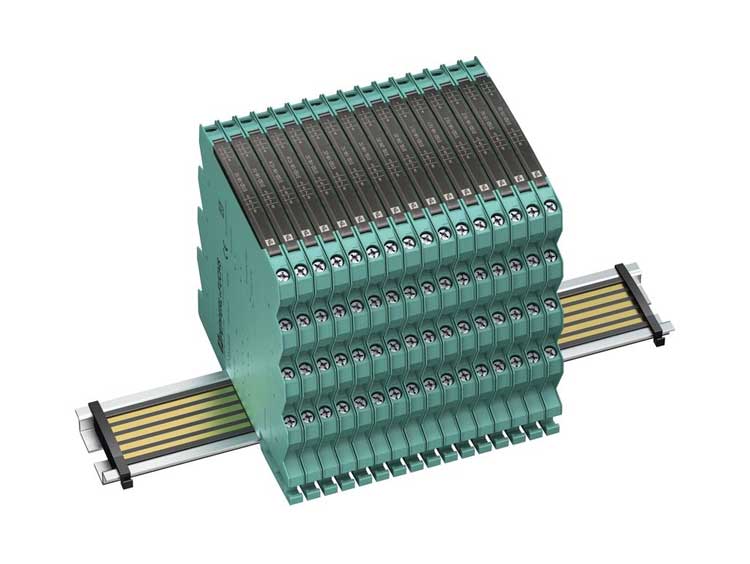

The K-system comprises signal conditioners for signal transfer between control system and safe area as well as isolated barriers for communication with field devices in hazardous areas. They are preferred for these kinds of mixed applications. Wide range of isolated barriers and signal conditioners for mixed applications

Modules for universal power supply

Reduced wiring by Power Rail

Removable terminals

Many modules with marine approvals and SIL assessment

The K-system comprises signal conditioners for signal transfer between control system and safe area as well as isolated barriers for communication with field devices in hazardous areas. They are preferred for these kinds of mixed applications. Wide range of isolated barriers and signal conditioners for mixed applications

Modules for universal power supply

Reduced wiring by Power Rail

Removable terminals

Many modules with marine approvals and SIL assessment -

The SC-system is a signal conditioner product family for applications without hazardous areas on the field side.

Modules for analog and digital signals

Transmitter power supplies, isolated amplifiers, passive isolators, signal converters, and switch amplifiers

24 V DC supply

Reduced wiring effort due to Power Bus

The SC-system is a signal conditioner product family for applications without hazardous areas on the field side.

Modules for analog and digital signals

Transmitter power supplies, isolated amplifiers, passive isolators, signal converters, and switch amplifiers

24 V DC supply

Reduced wiring effort due to Power Bus -

VANTAGE 4800

Single & Multipath Spool Construction. The Engineering Team at Eastech believed that in order to absolutely meet all of the requirements of AWWA/ANSI C750–03, a flowmeter had to be designed that not only adhered to every section of the Standard, but also eliminated any possibility of improper installation, inaccurate velocity measurements, and less than adequate calibration procedures. A flowmeter, in order to meet these requirements, would have to possess the following features:

Factory aligned spoolpiece sensors for guaranteed installed accuracy

High accuracy flow measurement under disturbed flow profiles

Advanced electronic meters with onboard dataloggers

NIST traceable calibration under actual operating conditions

VANTAGE 4800

Single & Multipath Spool Construction. The Engineering Team at Eastech believed that in order to absolutely meet all of the requirements of AWWA/ANSI C750–03, a flowmeter had to be designed that not only adhered to every section of the Standard, but also eliminated any possibility of improper installation, inaccurate velocity measurements, and less than adequate calibration procedures. A flowmeter, in order to meet these requirements, would have to possess the following features:

Factory aligned spoolpiece sensors for guaranteed installed accuracy

High accuracy flow measurement under disturbed flow profiles

Advanced electronic meters with onboard dataloggers

NIST traceable calibration under actual operating conditions

-

SIY PC-Programmable Signal

Isolator/Converter combines smart digital technology

with advanced analog operation to deliver superior

reliability, accuracy, and ease of use.

The highly versatile SIY programs to accept a wide

range of current or voltage inputs. It outputs an

isolated, proportional, 4-20mA signal. As a fl exible

analog/digital hybrid, this 2-wire (loop-powered)

transmitter programs in seconds to handle a wide

range of important signal interface applications.

SIY PC-Programmable Signal

Isolator/Converter combines smart digital technology

with advanced analog operation to deliver superior

reliability, accuracy, and ease of use.

The highly versatile SIY programs to accept a wide

range of current or voltage inputs. It outputs an

isolated, proportional, 4-20mA signal. As a fl exible

analog/digital hybrid, this 2-wire (loop-powered)

transmitter programs in seconds to handle a wide

range of important signal interface applications. -

SLD Functional Safety Programmable Loop Display

Moore Industries’ universal SLD PC-Programmable Functional Safety Loop Display features a large integral display that shows real-time process status in mA, percent, or any designated 5-character Engineering units (EGU). The SLD is part of Moore Industries’ FS Functional Safety Series products. It is certified by exida as a SIL3 capable, non-interfering device for use in a safety loop. The SLD Functional Safety Programmable Loop Display is the perfect solution to accurately and reliably display process status in a safety loop:Features:

-

SIL3 Capability. The SLD is certifi ed by exida for non-interference in a safety loop. (It is not SIL3 assessed or certifi ed to be used as part of the safety function).

-

Easy-to-read, customizable display. The SLD’s independently confi gured display features two rows of large characters that can be clearly read in the fi eld and set to display any EGU.

-

360° fl exible mounting. When placed into one of our housings, the SLD can be mounted at any angle in nearly any environment.

-

Low voltage drop. Loop-powered by less than 2.3 Volts, the SLD can even be installed on burdened loops.

-

Loop Maintenance Zener Diode Option. Allows the SLD to be removed from the loop for maintenance without interrupting your safety function.

-

Custom and square root curves. Select a square root or linear curve from the library, or create your own. Use our software to input a table in one EGU and have the PC program convert it into a different EGU for display.

-

-

The universal SPA2 Programmable Limit Alarm Trips provide on/off control, warn of unwanted process conditions, alarm on rate-of-change and provide emergency shutdown. Very versatile, they accept a signal input from transmitters, temperature sensors and a wide array of other monitoring and control instruments

The universal SPA2 Programmable Limit Alarm Trips provide on/off control, warn of unwanted process conditions, alarm on rate-of-change and provide emergency shutdown. Very versatile, they accept a signal input from transmitters, temperature sensors and a wide array of other monitoring and control instruments -

The universal SPA2IS Programmable Limit Alarm Trips provide on/off control, warn of unwanted process conditions, alarm on rate-of-change and provide emergency shutdown. Very versatile, they accept signal inputs from transmitters and temperature sensors that are located in hazardous areas where the method of protection implemented by the plant or facility is Intrinsic Safety.

The universal SPA2IS Programmable Limit Alarm Trips provide on/off control, warn of unwanted process conditions, alarm on rate-of-change and provide emergency shutdown. Very versatile, they accept signal inputs from transmitters and temperature sensors that are located in hazardous areas where the method of protection implemented by the plant or facility is Intrinsic Safety. -

The universal SPD Programmable Loop Display accepts a 4-20mA input from a process transmitter or similar analog device and indicates real-time process status in mA, percent or any designated engineering unit (EGU) on its 5-digit display. Both the process value and engineering unit (up to 5 characters) are shown on the display.

The universal SPD Programmable Loop Display accepts a 4-20mA input from a process transmitter or similar analog device and indicates real-time process status in mA, percent or any designated engineering unit (EGU) on its 5-digit display. Both the process value and engineering unit (up to 5 characters) are shown on the display. -

Jogler’s Specific Gravity Analyzers (SGAs) are a dependable and accurate method for measuring and sampling process liquid levels in virtually any application: – Acids – Caustics – Co-generation – Light Hydrocarbons – Beverages, etc.

Specific Gravity Analyzers are engineered for ease of installation and high reliability

SGAs present accurate visual verification of liquid density, can be cross-checked against temperature and are compatible with most requirements. Also, they require only small amounts of product for specific gravity measurement. SGAs are available in two standard configurations and two materials.

The hydrometer sleeve and sight tube are made of heavy wall borosilicate and the sight chamber is sealed with Teflon Super seals. The Jogler SGAs are equipped with 0.25” FNPT valves for flow control and sampling and the hydrometer is high-visibility and accurate. Installation and maintenance are engineered for simplicity and ease of use.

Jogler’s Specific Gravity Analyzers (SGAs) are a dependable and accurate method for measuring and sampling process liquid levels in virtually any application: – Acids – Caustics – Co-generation – Light Hydrocarbons – Beverages, etc.

Specific Gravity Analyzers are engineered for ease of installation and high reliability

SGAs present accurate visual verification of liquid density, can be cross-checked against temperature and are compatible with most requirements. Also, they require only small amounts of product for specific gravity measurement. SGAs are available in two standard configurations and two materials.

The hydrometer sleeve and sight tube are made of heavy wall borosilicate and the sight chamber is sealed with Teflon Super seals. The Jogler SGAs are equipped with 0.25” FNPT valves for flow control and sampling and the hydrometer is high-visibility and accurate. Installation and maintenance are engineered for simplicity and ease of use. -

SRM FS FUNCTIONAL SAFETY RELAY MODULE

SRM Safety Relay Module provides a high level of availability for safety-critical applications and as a part of Safety Instrumented Systems (SIS). It has been developed following the IEC 61508 standard and is certified by exida for single use in Safety Instrumented Systems up to SIL 2. The SRM is a relay repeater model that accepts a single contact closure input from a logic solver trip output such as the Moore Industries STA Safety Trip Alarm or the SPA2 Programmable Limit Alarm Trip. The SRM provides three contacts per alarm input, allowing you to add alarm contacts for your safety processes without special installation or configuration. Force Guided Relay Unlike traditional multi-output off-the-shelf interposing relays, the SRM is built using a safety-rated relay with forcibly-guided contacts. This design is commonly used in control and safety systems where the logic of an application needs to detect the state of the output contacts. This is achieved by monitoring the state of the monitor contact that is also mechanically linked to the same armature as the output contacts. A Force Guided Relay avoids the possibility of having contacts stuck in the Normally Open (NO) and Normally Closed (NC) states at the same time. Also known as a Positively Guided Relay, the Force Guided Relay assures users that mechanical problems such as welded contacts won’t be missed. Rugged Housing The SRM is housed in a DIN case that can be mounted on 35mm Top-Hat DIN-rail. The aluminum housing is more rugged and durable than safety relays housed in a plastic case.Features:

- exida certified to IEC 61508. exida has certified the SRM for single use in a Safety Instrumented System up to SIL 2.

- Comprehensive FMEDA certified safety data.Upon request, exida-certifi ed FMEDA (Failure Modes, Effects and Diagnostics Analysis) data is provided to be used by a competent functional safety practitioner to determine the SRM’s applicability in specific safety-related applications.

- Visual diagnostic information. Front-panel LEDs provide diagnostic information, with three LED indicator lights that show the Input, Output and Power status. The panels provide an instant visual diagnostic on the SRM, setting users quickly see if there are any potential problems.

- Easy to install and configure. The SRM can be installed in a Safety Instrumented System with minimal wiring. Simply provide a contact closure input to the SRM and you get three process relay outputs. A monitor relay is also provided.

- Input Snubber. The Contact Closure input circuit includes an internal snubbing diode across its relay coil, meaning there is no need for external suppression across the input terminals.

- Fuse protection. Input power and all four relay outputs on the SRM are fuse protected.

- RFI/EFI protection. Enhanced RF immunity up to 20V/m, 20-1000MHz when tested to IEC 61000-4-3.

-

SSX/SST Safety Series Isolator & Splitter

FS Functional Safety Series, the exida® approved, SIL 3 capable 2-wire (loop powered) SSX and 4-wire (line/mains powered) SST Safety Isolators and Splitters provide isolation and signal conversion for your SIS (Safety Instrumented System) needs. These units protect and enhance loops and also pass valuable HART® data from the field transmitter to host systems and vice-versa.Isolate your SIS from your Basic Process Control System or monitoring system so disconnections or failures to these secondary systems don’t affect your safety system. FMEDA (Failure Mode Effects and Diagnostic Analysis) reports are available with the required safety data to ensure that risk reduction requirements are met.Protect your safety system from surges, spikes and transients in the field. With 1500Vrms isolating capability, the SSX/SST protects your safety I/O cards and system from the rigors of plant environments.With built-in HART pass-through technology you can rest assured that when your loops use HART transmitters that critical and valuable HART diagnostic, process, and calibration information can be read on either side of the SSX/SST. Most all other isolators block and “strip off” the HART signal.Features:

- exida certified IEC 61508:2010. exida has certified the SSX/SST for use in an SIS up to SIL 3 in monitor mode, where only the input circuit is part of the safety function. For single use mode, the SSX/SST is approved for use in an SIS up to SIL 2.

- Comprehensive FMEDA certified safety data. Upon request, exida-certified FMEDA data is provided to be used by a functional safety practitioner to determine the SST’s and SSX’s applicability in specific safety-related applications.

- Valuable HART data not lost. Both the SSX and SST pass critical HART data to asset management systems, programming devices or host systems.

- Split signals between two locations. The 4-Wire SST takes in one signal and gives you two fully isolated outputs that can be taken to two separate receiving devices. This facilitates maintenance on either output loop without losing the signal on the other output loop.

- RFI/EMI Protection. Standard 20V/m protection offered to protect against harmful effects of radio frequency and electromagnetic interference.

- Transmitter excitation. The 4-wire SST is capable of providing loop power to a 2-wire transmitter that is connected to its input.

-

STA SIL 2 and SIL 3 Compliant Programmable Current/Voltage and RTD/Thermocouple Safety Trip Alarms

The exida® SIL 2 and SIL 3 certified STA Safety Trip Alarm performs as a logic solver and acts on potentially hazardous process conditions; warns of unwanted process conditions; provides emergency shutdown; or provides on/off control in Safety Instrumented Systems (SIS) and traditional alarm trip applications. The 4-wire (line/mains-powered) STA models accept a signal input from transmitters, temperature sensors and a wide array of other monitoring and control instruments including:Current and Voltage Signals Temperature (RTD and T/C) Sensor Inputs Resistance and Potentiometer Devices Direct Millivolt Sources

Features:

- exida certified IEC 61508:2010. For systematic integrity up to SIL 3 and for random integrity up to SIL 2. This means that an STA is approved for single use in Safety Instrumented Systems (SIS) up to SIL 2 and in redundant architectures (1oo2, 2oo3, etc.) up to SIL 3.

- Comprehensive FMEDA certified safety data. Upon request, exida-certified FMEDA (Failure Modes, Effects and Diagnostics Analysis) data is provided to be used by a competent functional safety practitioner to determine the STA’s applicability as a logic solver in specific safety-related applications.

- 20-bit input resolution with long-term stability. Delivers industry-best digital accuracy with up to 5 years between scheduled calibrations.

- Site-programmable with password protection. Front panel pushbuttons with menu-guided configuration deliver confident and secure set up.

- Large 5-digit process and status readout. Backlit display shows menu prompts during configuration and, when in operation, shows the process variable, the output or toggles between the two in selectable engineering units.

- Isolated and RFI/EMI protection. Delivers superior protection against the effects of ground loops and plant noise.

- Combined alarm trip and transmitter. The analog output (-AO) option reduces costs and installation time when both alarm and transmitter functions are needed at the same location.

-

MicroMod’s SteamPAK series of pre-engineered boiler-control packages are available for steam and hot water, gas and/or oil, and single or dual fuel boilers. These ready-to-install solutions offer pre-programmed controllers and application-specific installation, startup, and operation manuals. And, now, our “plug-and-play” performance has been further enhanced for even greater simplicity and flexibility

MicroMod’s SteamPAK series of pre-engineered boiler-control packages are available for steam and hot water, gas and/or oil, and single or dual fuel boilers. These ready-to-install solutions offer pre-programmed controllers and application-specific installation, startup, and operation manuals. And, now, our “plug-and-play” performance has been further enhanced for even greater simplicity and flexibility -

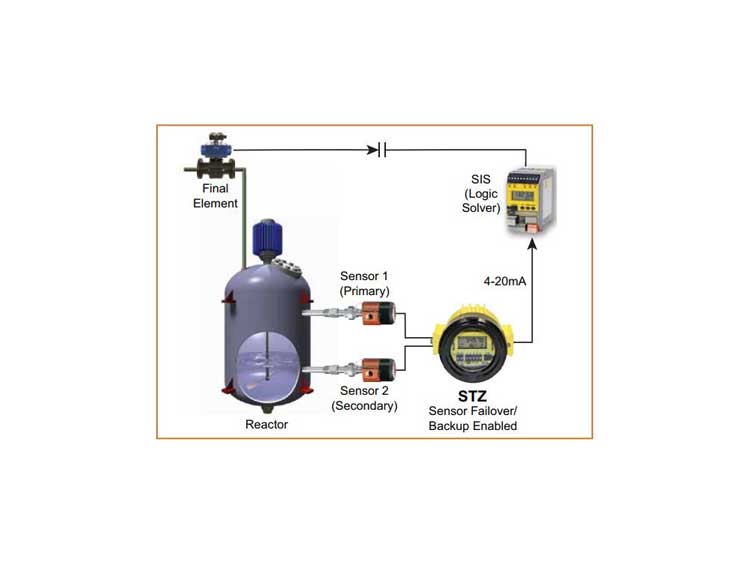

The SIL 2 and SIL 3 capable STZ Functional Safety Dual Input Smart HART® Temperature Transmitters for your SIS (Safety Instrumented System) confi gures quickly and easily to accept a single or dual input from a wide array of sensors and analog devices:

The SIL 2 and SIL 3 capable STZ Functional Safety Dual Input Smart HART® Temperature Transmitters for your SIS (Safety Instrumented System) confi gures quickly and easily to accept a single or dual input from a wide array of sensors and analog devices:- 14 RTD Types

- 9 Thermocouple Types

- Resistance and Potentiometer Devices

- Direct Millivolt Sources

Features:

- STZ-DIN Functional Safety Dual Input Smart HART® Temperature Transmitter now includes associated Intrinsically-Safe Sensor Connections. The intrinsically–safe –AIS option allows direct connection of sensors located in Non-Hazardous or Class 1, Division 2/Zone 2 hazardous locations with sensor input terminals connected to equipment or sensors located in Class I , II III, Division 1 /Zone 0/1 hazardous locations since it includes an internal intrinsically-safe barrier in the front end of the THZ3.

- exida certifi ed to IEC 61508:2010. Certified by exida to IEC 61508 for systematic integrity up to SIL 3 and for random integrity up to SIL 2. This means that an STZ is approved for single use in Safety Instrumented Systems (SIS) up to SIL 2 and in a redundant architecture (1oo2, 2oo3, etc.) up to SIL 3.

- Comprehensive FMEDA certified safety data. Upon request, exida-certified FMEDA data is available for a functional safety practitioner to use in determining the STZ applicability in specific safety-related applications.

- Dual sensor input for Backup and Failover Protection, Average and Differential measurement and Low or High Select.

- Device Intelligence including Sensor Drift and Corrosion Detection, Smart Range Alarms, High-availability option, and Input Simulation capability.

- HART 7 compliant with exception-based reporting and dynamic variable mapping.

- HART Access Control. To prevent unauthorized or accidental reconfiguration of the STZ while it's performing it's safety function, it has an added security feature to allow users to set HART communication into a Read Only or Off mode.

- Input-to-output analog accuracy of up to ±0.014°C (±0.025°F)* is the absolute best in the industry.

- 20-bit input resolution delivers exceptional digital accuracy of ±0.1°C (±0.18°F) with all Pt RTDs or up to ±0.05°C (±0.09°F)* for Pt1000 RTDs.

- HART & DTM Programmable with user-oriented basic configuration for fast and accurate setup. HART configurable via any HART handheld configurator or HART compatible host. Additionally program or monitor with any FDT compliant host or program, such as PACTware, utilizing our DTM.

- Long-term stability provides up to 5 years between scheduled calibrations.

-

SV SERIES STABILIZED CONNECTORS WITH INTEGRAL VALVE

NOSHOK STABILIZED CONNECTORS WITH INTEGRAL VALVE are also designed to reinforce an installation by shifting radial-stress load away from the NPT connections, but also feature a block valve that can be installed on either side of stabilized body, allowing 1/2 turn installation. SV Series Stabilized Connectors with Integral Valve are available in zincnickel plated carbon steel and 316 stainless steel, and feature slotted bolt holes that allow for 2-1/8" and 2-1/4" bolt spacings.The integral valve has a 0.375" bore for unrestricted passage of process gas, and a standard non-rotating stem tip. This application will work on both flat surfaces (orifice fitting) and round surfaces (orifice flange) with flange adaptor. A single piece dielectric gasket (DK1) is available as an option to create a non-conductive shield between the process piping and the instrument. A two piece dielectric kit (DK2) is also available as an alternative when a separate sealing gasket or o-ring is required. Stainless steel bolts are also available.

SV SERIES STABILIZED CONNECTORS WITH INTEGRAL VALVE

NOSHOK STABILIZED CONNECTORS WITH INTEGRAL VALVE are also designed to reinforce an installation by shifting radial-stress load away from the NPT connections, but also feature a block valve that can be installed on either side of stabilized body, allowing 1/2 turn installation. SV Series Stabilized Connectors with Integral Valve are available in zincnickel plated carbon steel and 316 stainless steel, and feature slotted bolt holes that allow for 2-1/8" and 2-1/4" bolt spacings.The integral valve has a 0.375" bore for unrestricted passage of process gas, and a standard non-rotating stem tip. This application will work on both flat surfaces (orifice fitting) and round surfaces (orifice flange) with flange adaptor. A single piece dielectric gasket (DK1) is available as an option to create a non-conductive shield between the process piping and the instrument. A two piece dielectric kit (DK2) is also available as an alternative when a separate sealing gasket or o-ring is required. Stainless steel bolts are also available. -

SWIVEL ADAPTORS

NOSHOK SWIVEL ADAPTORS are used with gauges and gauge valves to adjust the line of sight. The swivel adaptor rotates 360° to allow the connected instrument to be positioned in the desired direction and has temperature ratings of 15,000 psi @ 200 °F and 3,000 psi @ 1,000 °F. The pressure connection is achieved with a tapered cone style compression fitting simply by tightening the swivel hex nut. They feature all 316 stainless steel construction, and are standard with 1/2" NPT male process – 1/2" NPT female instrument connections. Also available with 1/4" NPT connections.

SWIVEL ADAPTORS

NOSHOK SWIVEL ADAPTORS are used with gauges and gauge valves to adjust the line of sight. The swivel adaptor rotates 360° to allow the connected instrument to be positioned in the desired direction and has temperature ratings of 15,000 psi @ 200 °F and 3,000 psi @ 1,000 °F. The pressure connection is achieved with a tapered cone style compression fitting simply by tightening the swivel hex nut. They feature all 316 stainless steel construction, and are standard with 1/2" NPT male process – 1/2" NPT female instrument connections. Also available with 1/4" NPT connections. -

MOD30 Process Controller Family. Formerly manufactured by Kent-Taylor and ABB, the MOD control family is now solely owned and manufactured by MicroMod Automation and Controls. Our ongoing development and enhancement program carries the legacy of quality and performance into the future with state-of-the-art components and manufacturing.

MOD30 Process Controller Family. Formerly manufactured by Kent-Taylor and ABB, the MOD control family is now solely owned and manufactured by MicroMod Automation and Controls. Our ongoing development and enhancement program carries the legacy of quality and performance into the future with state-of-the-art components and manufacturing. -

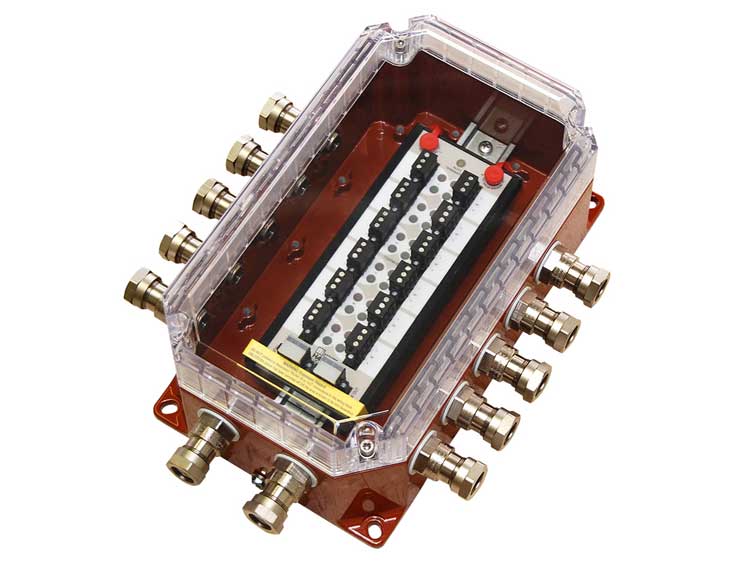

Terminal Junction Boxes Glass Fiber Reinforced Polyester (GRP) GL***.T

Glass fiber reinforced polyester (GRP) enclosure

Ex e, Ex ia and Ex tb certified

16 enclosure size options

Customizable configuration of terminals, cable entries and cable gland types as per specification

Installation in Zone 1, Zone 2, Zone 21 and Zone 22

Wide range of accessories available

Terminal Junction Boxes Glass Fiber Reinforced Polyester (GRP) GL***.T

Glass fiber reinforced polyester (GRP) enclosure

Ex e, Ex ia and Ex tb certified

16 enclosure size options

Customizable configuration of terminals, cable entries and cable gland types as per specification

Installation in Zone 1, Zone 2, Zone 21 and Zone 22

Wide range of accessories available -

Designed for General Purpose ,Non-Incendive and Zone 2 applications, TRUNKGUARD Series 200 Device Couplers (TG200) enable fast and easy implementation of fieldbus systems by connecting multiple devices to a main fieldbus trunk in FOUNDATION fieldbus™ H1 and PROFIBUS PA networks. TG200 Device Couplers are available in models that handle four to 20 fieldbus devices.

Designed for General Purpose ,Non-Incendive and Zone 2 applications, TRUNKGUARD Series 200 Device Couplers (TG200) enable fast and easy implementation of fieldbus systems by connecting multiple devices to a main fieldbus trunk in FOUNDATION fieldbus™ H1 and PROFIBUS PA networks. TG200 Device Couplers are available in models that handle four to 20 fieldbus devices. -

Device Couplers provide easy and practical mechanisms for implementing fieldbus systems. TRUNKGUARD Series 300 Device Couplers (TG300) simplify the use of fieldbus devices in Zone 1 by allowing “live” access for maintenance and eliminating the need for Exd junction boxes. The TG300 Series offers our patented Automatic Segment Termination feature and a key-operated magnetic interlock which permits one spur at a time to be de-energized and worked on without shutting down the entire segment.

Device Couplers provide easy and practical mechanisms for implementing fieldbus systems. TRUNKGUARD Series 300 Device Couplers (TG300) simplify the use of fieldbus devices in Zone 1 by allowing “live” access for maintenance and eliminating the need for Exd junction boxes. The TG300 Series offers our patented Automatic Segment Termination feature and a key-operated magnetic interlock which permits one spur at a time to be de-energized and worked on without shutting down the entire segment. -

The 330 is a process monitor with universal input that is multi-functional and microprocessor based. The 330 can function as a panel meter and trip (alarm), or as a panel meter with two trips (alarms), analog transmitter and digital transmission with the addition of the RS 485 serial communications option.

The 330 is a process monitor with universal input that is multi-functional and microprocessor based. The 330 can function as a panel meter and trip (alarm), or as a panel meter with two trips (alarms), analog transmitter and digital transmission with the addition of the RS 485 serial communications option. -

The ALH Series of peristatlic pumps provide high levels of volumetric accuracy for sampling and metering applications. ALH Series pumps are available in 15 different sizes that provide flow rates up to 38,000 GPH. The low maintenance, seal-less design eliminates leaks, contamination and wear problems associated with difficult to seal products.

Self priming high capacity pump can be run dry without damage. Flow rates from 0.02 to 387 GPM (1 to 23,220 GPH). Pressures to 217 psi.

The ALH Series of peristatlic pumps provide high levels of volumetric accuracy for sampling and metering applications. ALH Series pumps are available in 15 different sizes that provide flow rates up to 38,000 GPH. The low maintenance, seal-less design eliminates leaks, contamination and wear problems associated with difficult to seal products.

Self priming high capacity pump can be run dry without damage. Flow rates from 0.02 to 387 GPM (1 to 23,220 GPH). Pressures to 217 psi. -

The ALP Series Industrial Hose Pump is a two roller Peristaltic pump designed to handle abrasive slurries, viscous fluids, and aggressive chemicals that are normally difficult to pump with other types of positive displacement technologies. The ALP Series is an ideal choice for metering, batching and transfer applications. Peristaltic pumps are becoming the standard for hard to handle fluids such as Sodium Hypochlorite that off-gas and vapor-lock diaphragm pumps. Self priming high capacity pump can be run dry without damage. Flow rates from 1 to 40 GPM (60 to 2400 GPH). Pressures to 60 psi.

The ALP Series Industrial Hose Pump is a two roller Peristaltic pump designed to handle abrasive slurries, viscous fluids, and aggressive chemicals that are normally difficult to pump with other types of positive displacement technologies. The ALP Series is an ideal choice for metering, batching and transfer applications. Peristaltic pumps are becoming the standard for hard to handle fluids such as Sodium Hypochlorite that off-gas and vapor-lock diaphragm pumps. Self priming high capacity pump can be run dry without damage. Flow rates from 1 to 40 GPM (60 to 2400 GPH). Pressures to 60 psi. -

The X4 Series is a rugged family of variable speed AC drives, built and designed for harsh industrial environments. They come with IP66/ UL Type 4X and IP55/UL Type 3R enclosures for the ultimate protection from potential hazards such as moisture, dust or extreme temperatures. Each drive features a built-in braking resistor that not only allows the X4 to handle higher inertial loads out of the box, but allow it to warm itself even in the coldest conditions.

The X4 Series is a rugged family of variable speed AC drives, built and designed for harsh industrial environments. They come with IP66/ UL Type 4X and IP55/UL Type 3R enclosures for the ultimate protection from potential hazards such as moisture, dust or extreme temperatures. Each drive features a built-in braking resistor that not only allows the X4 to handle higher inertial loads out of the box, but allow it to warm itself even in the coldest conditions. -

THERMOWELLS

NOSHOK THERMOWELLS are recommended whenever the process being measured may be under pressure, is corrosive, abrasive or may be at a high velocity. They are also recommended as protection to the operator. The correct thermowell will reduce the possibility of damage to the temperature instrument and allows an instrument to be removed and replaced without shutting down and possibly draining the process. Standard thermowells are supplied with 1/2" NPSM instrument connection. The female thread will accept the 1/2" NPT male thread without galling or seizing.

THERMOWELLS

NOSHOK THERMOWELLS are recommended whenever the process being measured may be under pressure, is corrosive, abrasive or may be at a high velocity. They are also recommended as protection to the operator. The correct thermowell will reduce the possibility of damage to the temperature instrument and allows an instrument to be removed and replaced without shutting down and possibly draining the process. Standard thermowells are supplied with 1/2" NPSM instrument connection. The female thread will accept the 1/2" NPT male thread without galling or seizing.