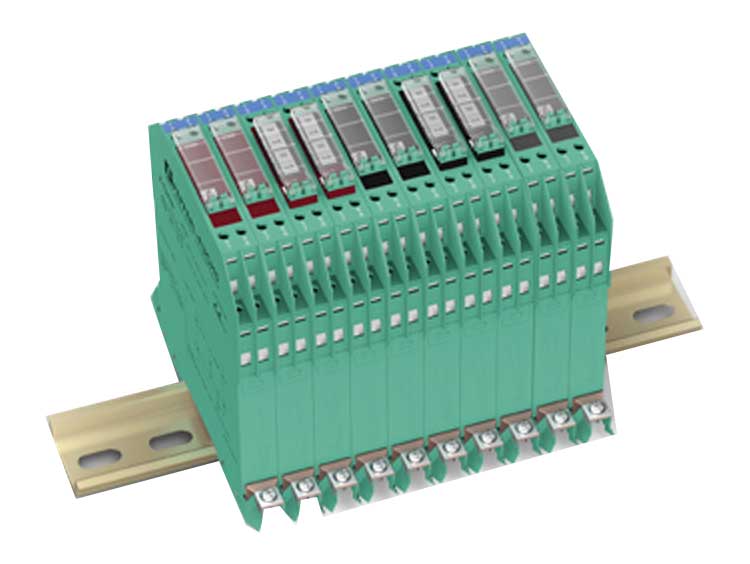

Z-system zener barriers are available with high density up to 2 channels / 12,5 mm width. Variants with field replaceable fuses provide a convenient means of disconnecting or open-circuiting the instrument loop without interfering with the wiring, making commissioning and maintenance operations much easier.

Z-system zener barriers are available with high density up to 2 channels / 12,5 mm width. Variants with field replaceable fuses provide a convenient means of disconnecting or open-circuiting the instrument loop without interfering with the wiring, making commissioning and maintenance operations much easier. -

XDF Explosion-Proof Duct Heater is designed for heating air or gases in hazardous environments where potentially explosive substances are present, such as oil refineries, coal mines, petrochemical plants and sewage treatment plants. They use heavy walled carbon steel finned tubular (Calrod® type)* elements with nickel plated finish to provide safe, efficient, low temperature heat transfer.

XDF Explosion-Proof Duct Heater is designed for heating air or gases in hazardous environments where potentially explosive substances are present, such as oil refineries, coal mines, petrochemical plants and sewage treatment plants. They use heavy walled carbon steel finned tubular (Calrod® type)* elements with nickel plated finish to provide safe, efficient, low temperature heat transfer. -

When wires can’t be run for practical or economic reasons, the WNM Wireless Network Module provides accurate and reliable point-to-point wireless connectivity between remote fi eld sites. The WNM is a bi-directional, spread spectrum radio modem that delivers the fl exibility and cost-saving advantages of wireless data transmission. It is ideal for use with Moore Industries’ NET Concentrator System® (NCS), as well as other SCADA and distributed I/O systems.

When wires can’t be run for practical or economic reasons, the WNM Wireless Network Module provides accurate and reliable point-to-point wireless connectivity between remote fi eld sites. The WNM is a bi-directional, spread spectrum radio modem that delivers the fl exibility and cost-saving advantages of wireless data transmission. It is ideal for use with Moore Industries’ NET Concentrator System® (NCS), as well as other SCADA and distributed I/O systems. -

WINSMART™ TY52 SMART EXPLOSION PROOF TEMPERATURE TRANSMITTER

DESCRIPTION & FEATURES

- Integrated temperature transmitter with ASIC signaling transmitter

- Explosion proof smart temperature transmitter for hazardous locations

- -50 to 400°C (-58/752°F ) measure range

- 0.5% accuracy

- Simple to operate 3-push button control

- HART® or Modbus communications available

- Low power option available

- Re-zero function for safe field calibration

- 10:1 rangeability allows for installation in any application

- 5 year warranty

APPLICATIONS

TY52 can be utilized and installed anywhere where temperature measurement is required. From Oil & Gas installations to Power Generation, this product has a rugged design and is equipped with the communication protocols to meet all your day to day requirements -

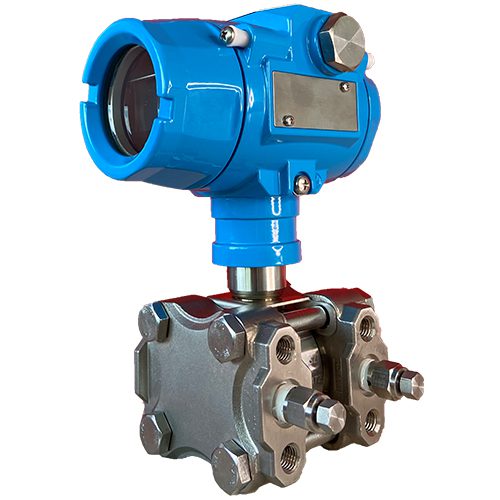

WINSMART™ LY36 SMART EXPLOSION PROOF DIFFERENTIAL PRESSURE TRANSMITTER

DESCRIPTION & FEATURES

- Monosilicone-based high performing transmitter

- Explosion-proof smart differential pressure transmitter for hazardous locations

- Sour gas NACE0175 compliant

- Built-in temperature sensor

- 0.075% or 0.05% accuracy

- Simple to operate 3-push button control

- HART® or Modbus communications are available

- Low power option available

- Re-zero function for safe field calibration

- 10:1 rangeability allows for installation in any application

- CRN Registered

- 5-year warranty

- Differential pressure transmitters are useful instruments for measuring the difference between two pressures. If you’re looking for a differential pressure transmitter, look no further! Our LY36 smart differential pressure transmitter is one of the top-performing differential pressure transmitters in the market.

APPLICATIONS

Differential pressure monitoring for oil and gas installations, well head process control, petrochemical installations, power generation equipment and all hazardous locations -

WINSMART™ LY16 SMART EXPLOSION PROOF PRESSURE TRANSMITTER

DESCRIPTION & FEATURES

- Microprocessor-based high performing transmitter

- Explosion-proof smart pressure transmitter for hazardous locations

- Sour gas NACE0175 compliant,Built-in temperature sensor

- 0.2% standard; 0.5%, 0.1%, 0.075% or 0.05% optional

- Simple to operate 3-push button control,HART® or Modbus communications are available

- Low power option available,Re-zero function for safe field calibration,10:1 rangeability allows for installation in any application,

- CRN Registered,5-year warranty

APPLICATIONS

Pressure monitoring for oil and gas, well head process control, petrochemical installations, power generation equipment and all hazardous locations. -

WIN-911

Integrating with the most sophisticated DCSs, HMI and SCADA systems in the world, WIN-911 delivers critical alarm alerts in real time

Dynamically responsive and highly configurable, WIN-911 can model any alarm notification workflow

WIN-911 direct connects provide native connections with leading SCADA, HMI and control systems enabling ease of configuration, performance optimization, and syncing of alarm acknowledgments and other data. Alarm subscriptions filter alerts into WIN-911, eliminating the need to maintain two databases for faster integration, simplified setup, and reduced maintenance.Features:

- Notification Options ... All notification options support single or bi-directional communications, acknowledgments, and custom formats.

- Mobile-911 Smart Phone Apps for Apple or Android

- SMS Text - supports Ethernet and serial based cellular modems

- Email - Rich HTML or plain text (SMTP, POP, IMAP, SSL/TLS)

- Voice - Text to speech, TAPI and VoIP (SIP) or analog phones (USB)

- Escalation Engine

- Drag and drop workflow creation

- Vary notifications based on severity, acknowledgement, date and time, or any other configurable attributes

- Create complex alarm escalation scenarios with rules based notification alarm workflows and if-then-else scenarios

- Notification Management

- Create dynamic alert schedules to cover rotating shifts, vacation requests and on-call status

- Supports ‘if-then-else’ scenario planning for complex notification strategies and timely alarm escalation

- Personnel Management

- Unlimited contacts

- Send alarms based on who is “on shift”

- Role-based notification assignments

- Scheduling

- Easy to use calendar tools

- Create complex rolling schedules

- Create shift schedules

- Web-based interface allows for quick schedule changes

- Reporting

- Report templates allow rapid configuration

- Plain text or rich text

- Schedule reports according to “rules” – fixed

- Periods, alarm conditions, or data values

- Receive reports on any device

- Logging

- View, sort and print alarm history

- Logs include notification attempts, confirmation, acknowledgements, events and error codes

- Annotate each line with “notes” feature

- Localization

- Localized in 9 languages = English, Spanish, Chinese, German, French, Hebrew, Arabic, Italian, Portuguese. Includes software configuration, alarm delivery and alarm interaction

- Notification Options ... All notification options support single or bi-directional communications, acknowledgments, and custom formats.

-

COVID-19 and VTScada Remote Interactive Training

For the safety of our customers and staff, we have canceled all in-person training courses until further notice. To ensure access to the training, we are pleased to offer Remote Interactive Training Courses. These are the same as in-person courses, except the instructor is on your screen instead of in the room. See a list of available courses below. A Remote Interactive Training Course includes:- A live instructor, not a recording.

- Interaction with the instructor, just like they were in the room; ask questions whenever you want.

- The opportunity for one-on-one instruction in the form of breakout rooms during the course.

- If you get stuck, you can share your screen with the instructor without worrying about who else is watching. The instructor can even take control for a few minutes to help guide you back on track.

- At the end of the course, you’ll have access to a recording of the entire session. Review any bits that you missed or need a refresher on. (Breakout rooms and one-on-one sessions are not recorded.)

- The pace, timing, material, and exercises are all the same as if you were present in a classroom.

Upcoming Training Courses

Courses listed below will be updated on demand.Courses listed below will be updated on demand.

DATES COURSE TYPE LOCATION STATUS Sep 21 – Sep 24, 2020 Advanced Configuration Remote Interactive Training Open Please call 905-760-9399 to register Dec 7 – Dec 10, 2020 Operation & Configuration Remote Interactive Training Open Please call 905-760-9399 to register Courses Descriptions and Materials

LEVEL I – Operation & Configuration Course

Operators and developers will learn about the many features of the VTScada monitoring and control software by creating a working, full-featured application from start to finish. This course will explain how to use the native display screens, connect to hardware, build new displays, work with alarms, configure security and much more.LEVEL 2 – Advanced Configuration

Experienced VTScada developers will learn advanced configuration techniques that allow them to go beyond the standard tools for building their applications. Knowledge of the topics covered in the Operation and Configuration course is recommended for anyone considering this advanced course.Request a Course at Your Location

Contact Larry McLean to request an onsite customized training course.Student Course Requirements

For In-Class Courses

- A Windows 10® laptop is required. Let us know if you need us to provide one – numbers are limited. See the OS & PC requirements.

- Travel and lodging arrangements are the responsibility of attendees.

- Spaces are limited, so please respond as soon as possible.

For Remote Interactive Training Courses

- A computer, on which you can install and run VTScada.

- A reasonably fast internet connection.

- A workspace where you can focus on the course.

- A working webcam. (Usually built into your laptop or tablet.) This will make you part of the class, not just a disembodied connection in a list.

- Headphones or a headset. These are not needed if you’re in a quiet space, or away from co-workers who don’t want to listen to the course broadcast from your computer speakers.

- A working microphone, either as part of your computer, headset, or webcam.

- Optional: A second screen, whether that’s a second monitor, a second laptop or a tablet. This allows you to have the course workbook file and the Remote Interactive Training session open on one screen while doing your exercises on another.

- If co-workers are attending the class with you, consider using a projector and sharing one set of speakers and a microphone, rather than having everyone run a separate copy of the virtual classroom. This will avoid audio feedback and reduce the load on your network connection. A webcam pointing back at the group is recommended.

- Ensure that any Bluetooth devices you are using are fully charged.

Continuing Education Credits

VTSCADA Operation & Configuration Course is approved for Continuing Ed Credits in the states of Florida, South Carolina, Louisiana, Tennessee, as well as the provinces of Nova Scotia, New Brunswick, Newfoundland & Labrador, and Prince Edward Island.Video Tutorials

Get started using VTScada by checking out Video Tutorials.More Information

- Larry McLean: Email or phone: 866.342.5222 Ext. 236

-

Instantly Intuitive HMI and SCADA Software

VTScada provides you with a refreshingly intuitive platform for creating highly-customized industrial monitoring and control applications that end users can trust and use with ease. A wide variety of industries around the world use VTScada for mission-critical applications of every size.More than HMI and SCADA Software

VTScada also natively includes components not commonly found in HMI or SCADA software platforms such as polling management, historian, trends viewer, report generation, application version control, alarm notification, and system backup. You install everything at once in just a few minutes.Fully Integrated SCADA Features

VTScada uses a unique architecture that integrates all core HMI SCADA software features into a single, easy-to-use package. This includes optional components which can be unlocked by simply updating the VTScada software license key. In addition to reducing development time, this ensures that critical SCADA software features like Alarm Notification remains tightly integrated over the entire life of your system. VTScada allows you to easily grow from a few hundred tags on a single laptop all the way up to a multi-million tag system spanning distributed synchronized servers. VTScada Datasheet -

VisuNet operator workstations are rugged and sleek. These operator workstations are approved for; Zone 1/21 (ATEX and IECEx) , Zone 2 (ATEX) , Zone 2 (ATEX), Class I, Div 2, and are also suitable for use in the safe area , Div. 1 , Div. 2 , Class I, Div 2, Zone 2 (ATEX) , Zone 2 (ATEX), Class I, Div 2

VisuNet operator workstations are rugged and sleek. These operator workstations are approved for; Zone 1/21 (ATEX and IECEx) , Zone 2 (ATEX) , Zone 2 (ATEX), Class I, Div 2, and are also suitable for use in the safe area , Div. 1 , Div. 2 , Class I, Div 2, Zone 2 (ATEX) , Zone 2 (ATEX), Class I, Div 2 -

VisuNet industrial monitors and panel PCs are constructed for process control. Each and every industrial monitor is manufactured to meet rigid safety and mechanical tolerances.

Download Data Sheet

VisuNet industrial monitors and panel PCs are constructed for process control. Each and every industrial monitor is manufactured to meet rigid safety and mechanical tolerances.

Download Data Sheet -

The Vantage 4000 is shipped to the field factory pre-programmed to the conditions set forth by the customer. Preprogramming specifications are electronically confirmed on the display of the transmitter. If changes to the meter’s factory pre-programming is required, re-programming can simply be accomplished on the meter keypad or through the Auto- Programming feature. This feature allows plant personnel to re-program the Vantage 4000 by simply downloading the revised flow data from a PC or laptop directly into the meter.• Water & Wastewater

• Sewage Treatment

• Acids & Toxic Liquids

• Petroleum Products

• HVAC & Irrigation

The Vantage 4000 is shipped to the field factory pre-programmed to the conditions set forth by the customer. Preprogramming specifications are electronically confirmed on the display of the transmitter. If changes to the meter’s factory pre-programming is required, re-programming can simply be accomplished on the meter keypad or through the Auto- Programming feature. This feature allows plant personnel to re-program the Vantage 4000 by simply downloading the revised flow data from a PC or laptop directly into the meter.• Water & Wastewater

• Sewage Treatment

• Acids & Toxic Liquids

• Petroleum Products

• HVAC & Irrigation -

The Vantage 2200 is a state-of-the-art microprocessor-based ultrasonic transmitter utilized for measurement of both liquid level and flow in open channels. The 2200 is equipped, as standard, with an internal data logger. More than 70 standard flow equations for flumes, weirs and open flow nozzles are stored in non-volatile memory. Dual sensors can be input to a single set of electronics for dual weir/flume or bar screen level applications. The Vantage 2200 is designed to be extremely user-friendly with an easy to read 20 character alphanumeric, self-prompting display and a menu-driven programming guide.

The Vantage 2200 is a state-of-the-art microprocessor-based ultrasonic transmitter utilized for measurement of both liquid level and flow in open channels. The 2200 is equipped, as standard, with an internal data logger. More than 70 standard flow equations for flumes, weirs and open flow nozzles are stored in non-volatile memory. Dual sensors can be input to a single set of electronics for dual weir/flume or bar screen level applications. The Vantage 2200 is designed to be extremely user-friendly with an easy to read 20 character alphanumeric, self-prompting display and a menu-driven programming guide. -

V100 MultiPurpose Industrial Variable Speed Drives. The V100 is available in 0.55 to 90 kW (0.75 - 125 HP) 230V and 1.1-160 kW (1.5 - 200 HP) 500V. The wall-mountable drive modules are easy to install and operate, with IP21/UL Type1 provided as standard. Options include IP54/UL Type12 and flange mounting. Standard features include built-in I/O with 3 option slots, integrated RS-485 and Ethernet-based communications, conformal coating and robust motor control features for reliability.

V100 MultiPurpose Industrial Variable Speed Drives. The V100 is available in 0.55 to 90 kW (0.75 - 125 HP) 230V and 1.1-160 kW (1.5 - 200 HP) 500V. The wall-mountable drive modules are easy to install and operate, with IP21/UL Type1 provided as standard. Options include IP54/UL Type12 and flange mounting. Standard features include built-in I/O with 3 option slots, integrated RS-485 and Ethernet-based communications, conformal coating and robust motor control features for reliability. -

TYPE 40 FLOW-THROUGH ANNULAR STYLE REPLACEABLE DIAPHRAGM SEALS

NOSHOK FLOW-THROUGH ANNULAR STYLE REPLACEABLE DIAPHRAGM SEALS are frequently used in abrasive media applications such as slurries, heavy sludges, chemical (synthetic polymers), and diffusers (flow measurement). Process liquid flowing through the pipe exerts pressure onto a flush-mounted flexible inner cylider containing clean, captive liquid; completely isolating instrumentation from the process flow and preventing plugging.

TYPE 40 FLOW-THROUGH ANNULAR STYLE REPLACEABLE DIAPHRAGM SEALS

NOSHOK FLOW-THROUGH ANNULAR STYLE REPLACEABLE DIAPHRAGM SEALS are frequently used in abrasive media applications such as slurries, heavy sludges, chemical (synthetic polymers), and diffusers (flow measurement). Process liquid flowing through the pipe exerts pressure onto a flush-mounted flexible inner cylider containing clean, captive liquid; completely isolating instrumentation from the process flow and preventing plugging. -

TYPE 29 HIGH VOLUMETRIC DISPLACEMENT NONREPLACEABLE DIAPHRAGM SEALS

NOSHOK HIGH VOLUMETRIC DISPLACEMENT NONREPLACEABLE DIAPHRAGM SEALS are an all welded, all metallic housing design that does not utilize an o-ring or gasket. Displacement is limited to 1.5 ml requiring the use of gauges with less than 4-1/2" dial size and Bourdon tube range no lower than 0 psi to 15 psi. Pressure rating is 2,500 psi.

TYPE 29 HIGH VOLUMETRIC DISPLACEMENT NONREPLACEABLE DIAPHRAGM SEALS

NOSHOK HIGH VOLUMETRIC DISPLACEMENT NONREPLACEABLE DIAPHRAGM SEALS are an all welded, all metallic housing design that does not utilize an o-ring or gasket. Displacement is limited to 1.5 ml requiring the use of gauges with less than 4-1/2" dial size and Bourdon tube range no lower than 0 psi to 15 psi. Pressure rating is 2,500 psi. -

TYPE 25/25H

NOSHOK STANDARD PRESSURE NON-REPLACEABLE DIAPHRAGM SEALS utilize an all welded, all metallic housing design, pressure rated to 2,500 psi. The housing and diaphragm are offered in a variety of materials to suit most applications. A flushing port is offered as an option.

NOSHOK ELEVATED PRESSURE NON-REPLACEABLE DIAPHRAGM SEALS utilize an all welded, all metallic housing design pressure rated to 5,000 psi. The housing and diaphragm are offered in a variety of materials to suit most applications. A flushing port is offered as an option.

TYPE 25/25H

NOSHOK STANDARD PRESSURE NON-REPLACEABLE DIAPHRAGM SEALS utilize an all welded, all metallic housing design, pressure rated to 2,500 psi. The housing and diaphragm are offered in a variety of materials to suit most applications. A flushing port is offered as an option.

NOSHOK ELEVATED PRESSURE NON-REPLACEABLE DIAPHRAGM SEALS utilize an all welded, all metallic housing design pressure rated to 5,000 psi. The housing and diaphragm are offered in a variety of materials to suit most applications. A flushing port is offered as an option. -

TYPE 12 SANITARY, CLAMPED-STYLE, ASME-BPE NONREPLACEABLE DIAPHRAGM SEALS

NOSHOK SANITARY, CLAMPED-STYLE, ASME-BPE NONREPLACEABLE DIAPHRAGM SEALS feature a flush mount diaphragm and all welded construction, making them ideal for food & beverage, SANITARY, CLAMPED-STYLE, ASME-BPE NONREPLACEABLE

DIAPHRAGM SEALS pharmaceutical and sanitary markets. They can accommodate process connection pipes from 1-1/2" through 3" sizes. Their clamped connection allows ease of installation and removal of seal for maintenance and cleaning.

TYPE 12 SANITARY, CLAMPED-STYLE, ASME-BPE NONREPLACEABLE DIAPHRAGM SEALS

NOSHOK SANITARY, CLAMPED-STYLE, ASME-BPE NONREPLACEABLE DIAPHRAGM SEALS feature a flush mount diaphragm and all welded construction, making them ideal for food & beverage, SANITARY, CLAMPED-STYLE, ASME-BPE NONREPLACEABLE

DIAPHRAGM SEALS pharmaceutical and sanitary markets. They can accommodate process connection pipes from 1-1/2" through 3" sizes. Their clamped connection allows ease of installation and removal of seal for maintenance and cleaning.