The F126-EG flow computer has been developed to calculate corrected gas volume at normal conditions. The corrected volumetric flow is calculated by measuring the uncorrected volumetric flow, actual line temperature and pressure which are processed with the equations stored in the flow computer. A compressibility factor can be set to approach a real gas behavior. The reference conditions can be defined as desired (e.g. 15°C or 60°F and 1.013 bar).

The display shows the compensated flow rate, total, accumulated total and the actual line temperature and pressure. On-screen engineering units like Nm³ are easily configured from a comprehensive selection.

The F126-EG flow computer has been developed to calculate corrected gas volume at normal conditions. The corrected volumetric flow is calculated by measuring the uncorrected volumetric flow, actual line temperature and pressure which are processed with the equations stored in the flow computer. A compressibility factor can be set to approach a real gas behavior. The reference conditions can be defined as desired (e.g. 15°C or 60°F and 1.013 bar).

The display shows the compensated flow rate, total, accumulated total and the actual line temperature and pressure. On-screen engineering units like Nm³ are easily configured from a comprehensive selection. -

The F126-EG flow computer has been developed to calculate corrected gas volume at normal conditions. The corrected volumetric flow is calculated by measuring the uncorrected volumetric flow, actual line temperature and pressure which are processed with the equations stored in the flow computer. A compressibility factor can be set to approach a real gas behavior. The reference conditions can be defined as desired (e.g. 15°C or 60°F and 1.013 bar).

The display shows the compensated flow rate, total, accumulated total and the actual line temperature and pressure. On-screen engineering units like Nm³ are easily configured from a comprehensive selection.

The F126-EG flow computer has been developed to calculate corrected gas volume at normal conditions. The corrected volumetric flow is calculated by measuring the uncorrected volumetric flow, actual line temperature and pressure which are processed with the equations stored in the flow computer. A compressibility factor can be set to approach a real gas behavior. The reference conditions can be defined as desired (e.g. 15°C or 60°F and 1.013 bar).

The display shows the compensated flow rate, total, accumulated total and the actual line temperature and pressure. On-screen engineering units like Nm³ are easily configured from a comprehensive selection. -

The F120 single loop controller has been designed to offer outstanding control performance and provide a reliable solution for a wide variety of flow control applications. The single loop flow controller accepts most pulse inputs from flow meters and has a 4 - 20 mA output for controlling a valve or pump. The F120 is part of the Fluidwell process controller family and is the alternative for local control loops.

The F120 single loop controller has been designed to offer outstanding control performance and provide a reliable solution for a wide variety of flow control applications. The single loop flow controller accepts most pulse inputs from flow meters and has a 4 - 20 mA output for controlling a valve or pump. The F120 is part of the Fluidwell process controller family and is the alternative for local control loops. -

The batch controllers of the N-Series are much more advanced compared to our F-Series and D-Series batch controllers. The N-Series distinguishes itself from other batch controllers by its very easy to use numerical keypad. Selecting and entering multiple preset values with the easy to press keys is astonishingly simple. The display is designed for batch processes: at a glance, the operator is aware of the indicated switch points and the actual state of the process. For your convenience the preset and the actual value with their engineering units are displayed simultaneously.

The batch controllers of the N-Series are much more advanced compared to our F-Series and D-Series batch controllers. The N-Series distinguishes itself from other batch controllers by its very easy to use numerical keypad. Selecting and entering multiple preset values with the easy to press keys is astonishingly simple. The display is designed for batch processes: at a glance, the operator is aware of the indicated switch points and the actual state of the process. For your convenience the preset and the actual value with their engineering units are displayed simultaneously. -

The F040 is a straight forward temperature indicator with large 26mm (1") high digits. The measuring unit to be displayed below the temperature is simply selected through an alphanumeric configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user-friendly solution! The configuration of the Span, off-set and number of decimals is done through software functions, without any sensitive DIP-switches or trimmers.

The F040 is a straight forward temperature indicator with large 26mm (1") high digits. The measuring unit to be displayed below the temperature is simply selected through an alphanumeric configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user-friendly solution! The configuration of the Span, off-set and number of decimals is done through software functions, without any sensitive DIP-switches or trimmers. -

The F050 is a straight forward pressure indicator with large 26mm (1") high digits. The measuring unit to be displayed below the pressure is simply selected through an alphanumeric configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user-friendly solution!

The configuration of the Span, off-set and number of decimals is done through software functions, without any sensitive DIP-switches or trimmers.

The F050 is a straight forward pressure indicator with large 26mm (1") high digits. The measuring unit to be displayed below the pressure is simply selected through an alphanumeric configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user-friendly solution!

The configuration of the Span, off-set and number of decimals is done through software functions, without any sensitive DIP-switches or trimmers. -

The F073 is a versatile level indicator with continuous level monitoring feature. It offers the ability to set one low level and one high level alarm value. If desired, an ignore function can be set up to allow for an incorrect level for a certain period of time. The configuration of the Span, off-set and number of decimals is done through software functions, without any sensitive DIP-switches or trimmers. The display shows the actual level, height or percentage, alarm values, alarm messages and status. On-screen engineering units are easily configured from a comprehensive selection.

The F073 is a versatile level indicator with continuous level monitoring feature. It offers the ability to set one low level and one high level alarm value. If desired, an ignore function can be set up to allow for an incorrect level for a certain period of time. The configuration of the Span, off-set and number of decimals is done through software functions, without any sensitive DIP-switches or trimmers. The display shows the actual level, height or percentage, alarm values, alarm messages and status. On-screen engineering units are easily configured from a comprehensive selection. -

The D090 is a local, panel mount indicator to display the actual process value, range and loop current. The measuring unit to be displayed is simply selected through an alfa-numerical configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user friendly solution! The configuration of Span, offset and number of decimals is done through software functions, without any sensitive dip-switches or trimmers.

The D090 is a local, panel mount indicator to display the actual process value, range and loop current. The measuring unit to be displayed is simply selected through an alfa-numerical configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user friendly solution! The configuration of Span, offset and number of decimals is done through software functions, without any sensitive dip-switches or trimmers. -

The MS 2500 flanged sensor are well suited for all application and flow ranges. The MS2500 is available in the widest range of diameters.

Features;

• Accuracy to +/-0.2% of rate from 1 to 33 ft/sec.

• Nineteen sizes from 1" to 48" Pipe Diameters.

• Flow ranges from 2.37 to 179,400 GPM.

• Pressures to 5600 PSI.

• Volumetric flow rate measurement independent of fluid viscosity, density and temperature.

• No moving parts for zero maintenance.

• Bi-directional flow measurement.

• No pressure drop through sensor.

• Optional Integral ground electrode eliminates grounding rings with plastic piping systems.

• Minimal straight pipe run required.

• Every sensor is factory wet-calibrated.

The MS 2500 flanged sensor are well suited for all application and flow ranges. The MS2500 is available in the widest range of diameters.

Features;

• Accuracy to +/-0.2% of rate from 1 to 33 ft/sec.

• Nineteen sizes from 1" to 48" Pipe Diameters.

• Flow ranges from 2.37 to 179,400 GPM.

• Pressures to 5600 PSI.

• Volumetric flow rate measurement independent of fluid viscosity, density and temperature.

• No moving parts for zero maintenance.

• Bi-directional flow measurement.

• No pressure drop through sensor.

• Optional Integral ground electrode eliminates grounding rings with plastic piping systems.

• Minimal straight pipe run required.

• Every sensor is factory wet-calibrated. -

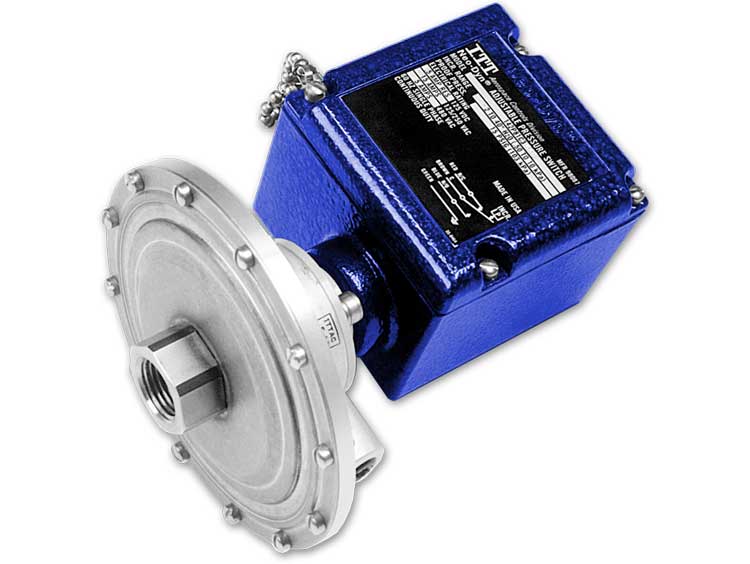

Series 100P (diaphragm sensor) for pneumatic and low impulse hydraulics up to 3000 psig system pressure

Versatile Nega-Rate® Belleville disc spring pressure switch for a wide range of applications.

Specifications

• Electrical: Snap action electrical switch recognized by Underwriters’ Laboratories, Inc. and CSA International

• Electrical Connection: 1/2 NPT female conduit connection with terminal block

• Pressure Connection:

o Wetted Material 1 1/4 NPT Female

o Wetted Material 4, 5, 7 and 9 1/2 NPT Female

• Temperature Range

o Ambient: -40°F to +180°F (-40°C to +82°C)

o Media: -40°F to +300°F (-40°C to +149°C)

• Media temperature limits change with O-Ring selection

• Adjustment: Concealed wrench flat adjustment with range scale

• Shipping Weight: Approximately 3 pounds

Series 100P (diaphragm sensor) for pneumatic and low impulse hydraulics up to 3000 psig system pressure

Versatile Nega-Rate® Belleville disc spring pressure switch for a wide range of applications.

Specifications

• Electrical: Snap action electrical switch recognized by Underwriters’ Laboratories, Inc. and CSA International

• Electrical Connection: 1/2 NPT female conduit connection with terminal block

• Pressure Connection:

o Wetted Material 1 1/4 NPT Female

o Wetted Material 4, 5, 7 and 9 1/2 NPT Female

• Temperature Range

o Ambient: -40°F to +180°F (-40°C to +82°C)

o Media: -40°F to +300°F (-40°C to +149°C)

• Media temperature limits change with O-Ring selection

• Adjustment: Concealed wrench flat adjustment with range scale

• Shipping Weight: Approximately 3 pounds -

142P8 NEMA 4X, 7, 9 & 13 Ultra Low Vacuum/Pressure Switch

Ultra-low pressure and vacuum to pressure crossover switch. Unique construction using efficient Nega-Rate® Belleville disc spring for stable set points and high proof pressure. Explosion proof enclosure and wide range of wetted materials makes this switch especially well-suited for hazardous or corrosive atmospheres.

Specifications

• Electrical: Snap action electrical switch listed by Underwriters’ Laboratories, Inc., FM Approval and CSA International

• Electrical Connection: 1/2 NPT male conduit connection with PVC insulated 18 AWG, 18” long leads

• Pressure Connection: 1/2 NPT Female

• Temperature Range*

o Ambient: -40°F to +180°F (-40°C to +82°C)

o Media: -50°F to +250°F (-46°C to +121°C)

• Adjustment: Concealed wrench flat adjustment with range scale

• Shipping Weight: Approximately 3.5 pounds

*Temperature limits change with O-Ring selection. See Electrical Assembly specification sheet for Temperature Class Ratings.

142P8 NEMA 4X, 7, 9 & 13 Ultra Low Vacuum/Pressure Switch

Ultra-low pressure and vacuum to pressure crossover switch. Unique construction using efficient Nega-Rate® Belleville disc spring for stable set points and high proof pressure. Explosion proof enclosure and wide range of wetted materials makes this switch especially well-suited for hazardous or corrosive atmospheres.

Specifications

• Electrical: Snap action electrical switch listed by Underwriters’ Laboratories, Inc., FM Approval and CSA International

• Electrical Connection: 1/2 NPT male conduit connection with PVC insulated 18 AWG, 18” long leads

• Pressure Connection: 1/2 NPT Female

• Temperature Range*

o Ambient: -40°F to +180°F (-40°C to +82°C)

o Media: -50°F to +250°F (-46°C to +121°C)

• Adjustment: Concealed wrench flat adjustment with range scale

• Shipping Weight: Approximately 3.5 pounds

*Temperature limits change with O-Ring selection. See Electrical Assembly specification sheet for Temperature Class Ratings. -

100T NEMA 4X, 7, 9 & 13 Temperature Switch/Internal Adjustment

Direct mount adjustable temperature switch for use in hazardous areas. Utilizes efficient Nega-Rate® Belleville spring mechanism and saturated vapor sensor for quick response and narrow deadband.

Specifications

• Electrical: Snap action electrical switch assembly listed by Underwriters’ Laboratories, Inc., FM Approval and CSA International

• Electrical Connection: 1/2 NPT male conduit connection with PVC insulated 18 AWG, 18" long leads

• Pressure Connection: 1/2 NPT Male; Direct mount

• Temperature Range:

o Ambient: -40°F to +180°F (-40°C to +82°C)

o See Electrical Assembly specification sheet for Temperature Class Ratings.

• System Pressure: 1500 psig maximum

• Proof Pressure: 2250 psig

• Adjustment: Concealed wrench flat adjustment with range scale

• Shipping Weight: Approximately 3 pounds

100T NEMA 4X, 7, 9 & 13 Temperature Switch/Internal Adjustment

Direct mount adjustable temperature switch for use in hazardous areas. Utilizes efficient Nega-Rate® Belleville spring mechanism and saturated vapor sensor for quick response and narrow deadband.

Specifications

• Electrical: Snap action electrical switch assembly listed by Underwriters’ Laboratories, Inc., FM Approval and CSA International

• Electrical Connection: 1/2 NPT male conduit connection with PVC insulated 18 AWG, 18" long leads

• Pressure Connection: 1/2 NPT Male; Direct mount

• Temperature Range:

o Ambient: -40°F to +180°F (-40°C to +82°C)

o See Electrical Assembly specification sheet for Temperature Class Ratings.

• System Pressure: 1500 psig maximum

• Proof Pressure: 2250 psig

• Adjustment: Concealed wrench flat adjustment with range scale

• Shipping Weight: Approximately 3 pounds -

162P NEMA 4X, 7, 9 & 13 Differential Pressure Switch

Adjustable high pressure differential switch. Rugged construction with efficient Nega-Rate® Belleville disc spring sensing mechanism. Maintains set point at high system pressure. Available in all stainless steel construction with hermetically sealed electrical assembly for corrosive atmospheres.

Specifications

• Electrical: Snap action electrical switch assembly listed by Underwriters’ Laboratories, Inc., FM Approval and CSA International

• Electrical Connection: 1/2 NPT male conduit connection with PVC insulated 18 AWG, 18" long leads

• Pressure Connections: 1/4 NPT Female

• Temperature Range*

o Ambient: -40°F to +180°F (-40°C to +82°C)

o Media: -40°F to +300°F (-40°C to +149°C)

• Adjustment: External 1/2" hex head

Note: Turn clockwise to increase set point; approximately 24 turns through range

• Shipping Weight:

o Aluminum: Approximately 3 lbs

o Stainless Steel: Approximately 7 lbs

*Temperature limits change with O-Ring selection. See Electrical Assembly specification sheet for Temperature Class Ratings.

162P NEMA 4X, 7, 9 & 13 Differential Pressure Switch

Adjustable high pressure differential switch. Rugged construction with efficient Nega-Rate® Belleville disc spring sensing mechanism. Maintains set point at high system pressure. Available in all stainless steel construction with hermetically sealed electrical assembly for corrosive atmospheres.

Specifications

• Electrical: Snap action electrical switch assembly listed by Underwriters’ Laboratories, Inc., FM Approval and CSA International

• Electrical Connection: 1/2 NPT male conduit connection with PVC insulated 18 AWG, 18" long leads

• Pressure Connections: 1/4 NPT Female

• Temperature Range*

o Ambient: -40°F to +180°F (-40°C to +82°C)

o Media: -40°F to +300°F (-40°C to +149°C)

• Adjustment: External 1/2" hex head

Note: Turn clockwise to increase set point; approximately 24 turns through range

• Shipping Weight:

o Aluminum: Approximately 3 lbs

o Stainless Steel: Approximately 7 lbs

*Temperature limits change with O-Ring selection. See Electrical Assembly specification sheet for Temperature Class Ratings.