ITC 7200 SERIES – UNVERSAL CONTROLLER- 48 Inputs

The ITC series advanced controllers and recorders have been designed for to handle and control advanced industrial applications.

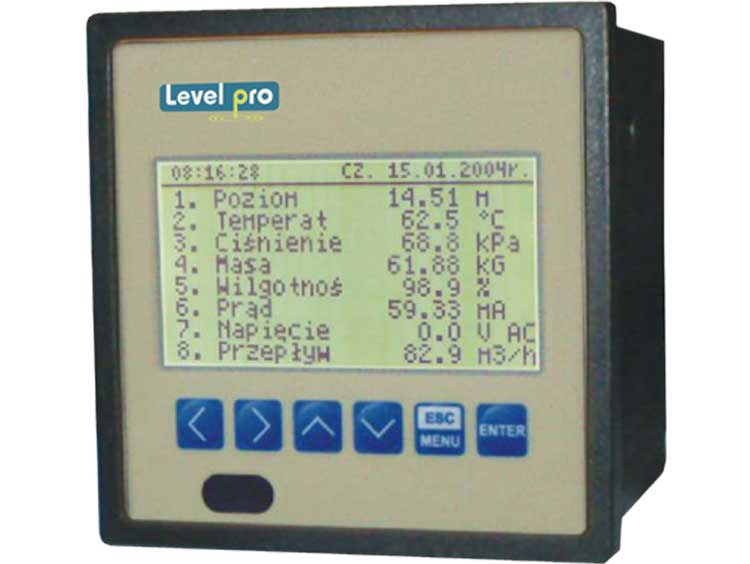

Applications:

- Temperature

- Flow

- Pressure

- PH

- Level

- Redox

- Humidity

- Current

Features:

Trending Diagrams

Universal Data Logger / Controller / Display ITC 7200 Series

1.5 GB for data! The ITC series data loggers can record channels at a speed of 10 samples per second. It has 1.5 GB built-in flash memory intended for data registration. .

DAQ Manager

To manage large amounts of data we have designed a software package that is free of charge. The software converts the data into easy viewing graphs and tables, and can provide group measurement results, create reports and export data into other files. Its fully functional free version can be downloaded from our website or ordered as a payable CD-ROM version.

Color LCD Touchscreen

The color touchscreen allows for easier and more efficient use of the device The display reacts accurately to even the slightest touch.

The ITC also allows for the use of a traditional keyboard and a USB mouse

Use Java applets

It is possible to create your own website or use one of the templates included in ITC series. Applications such as tank level via with bar graphs, flow meters indicating flow speed or total liquid flow, a pressure gauge indicating process pressure...all are possible with the ITC series This solution makes monitoring of the entire system much more transparent and simple to use.

Measure / Recalculate / Control and Display

Calculate the data according to your own requirements; one result can be used as an argument of another action. An example, current measurement from 8 channels and voltage from 8 channels cross checked against the total power from 8 items being measured. All data can be visualized in a range of ways: as numerical values, quasi-analog indicators, phasor charts, horizontal or vertical charts, horizontal or vertical bars.

Manage a Developed Network of Devices

For more demanding customers with many needs we have prepared the Advanced Communication Module (ACM). This module includes interfaces such as: Ethernet, USB Host, RS-485 and RS-485 shared with RS-232. All the Modbus interfaces can work in both master and slave mode. Through the utilization of an Ethernet link the user can monitor operation of the entire system via the Internet from anywhere in world, via an INTERNET browser. In addition the data can be monitored via the RS-485 interface along with PC software.

Specification:

- Power Supply: 19 to 50VDC , 16 to 35VAC , 85 to 260VAC/DC

- Inputs: Universal, Thermocouples: J,K,S,T,N,R,B,E(PNEN), L(GOST), RTD 2-3 wire, Pt100, Pt500,Pt1000, (PN_EN),GOST Ni100, Ni500, Ni1000(PN-En), Cu50,Cu100 (Pn-83M-53852), Universal pulse 5kHz

- Outputs: 4-20madc, SPST Rely 1A/250V

- Communications: RS485, Modbus RTU

- Operating Temperature: 0°C to 50°C