Kepware's KEPServerEX

Connects disparate devices and applications, from plant control systems to enterprise information systems

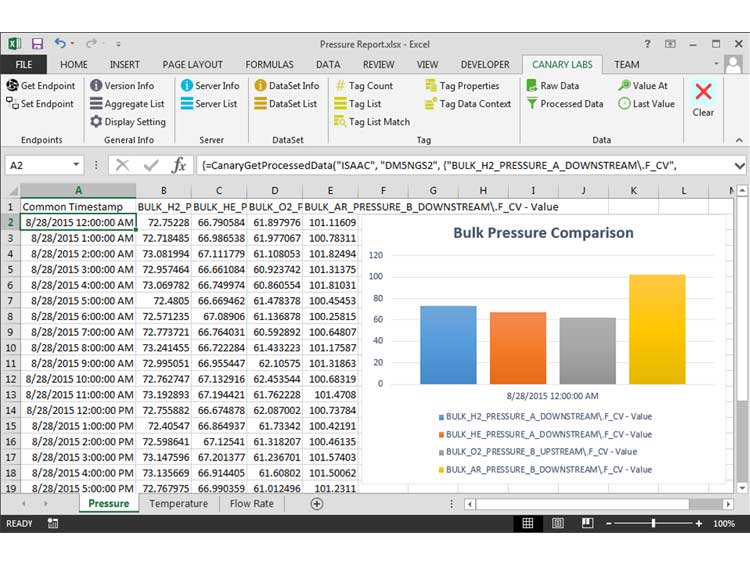

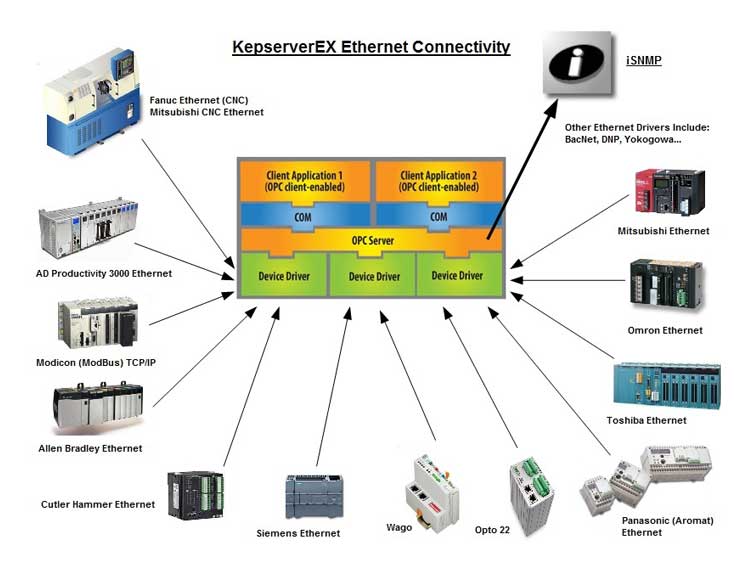

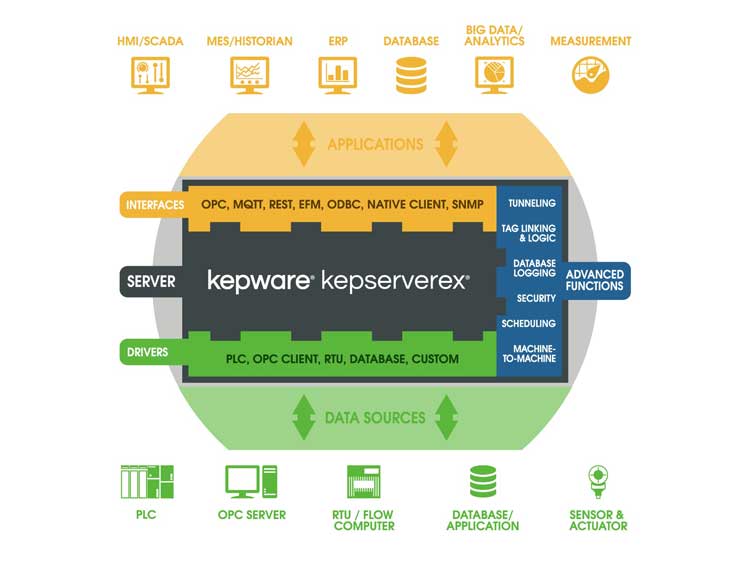

KEPServerEX is the industry’s leading connectivity platform that provides a single source of industrial automation data to all of your applications. The platform design allows users to connect, manage, monitor, and control diverse automation devices and software applications through one intuitive user interface. KEPServerEX leverages OPC (the automation industry’s standard for interoperability) and IT-centric communication protocols (such as SNMP, ODBC, and web services) to provide users with a single source for industrial data. The platform is developed and tested to meet our customers’ performance, reliability, and ease-of-use requirements.

Business Value:

KEPServerEX provides the industrial connectivity, usability, and performance required by the enterprise—offering competitive benefits that can be experience from the plant floor to IT to the boardroom.

Features: