SSX/SST Safety Series Isolator & Splitter

FS Functional Safety Series, the exida® approved, SIL 3 capable 2-wire (loop powered) SSX and 4-wire (line/mains powered) SST Safety Isolators and Splitters provide isolation and signal conversion for your SIS (Safety Instrumented System) needs. These units protect and enhance loops and also pass valuable HART® data from the field transmitter to host systems and vice-versa.

Isolate your SIS from your Basic Process Control System or monitoring system so disconnections or failures to these secondary systems don’t affect your safety system. FMEDA (Failure Mode Effects and Diagnostic Analysis) reports are available with the required safety data to ensure that risk reduction requirements are met.

Protect your safety system from surges, spikes and transients in the field. With 1500Vrms isolating capability, the SSX/SST protects your safety I/O cards and system from the rigors of plant environments.

With built-in HART pass-through technology you can rest assured that when your loops use HART transmitters that critical and valuable HART diagnostic, process, and calibration information can be read on either side of the SSX/SST. Most all other isolators block and “strip off” the HART signal.

Features:

- exida certified IEC 61508:2010. exida has certified the SSX/SST for use in an SIS up to SIL 3 in monitor mode, where only the input circuit is part of the safety function. For single use mode, the SSX/SST is approved for use in an SIS up to SIL 2.

- Comprehensive FMEDA certified safety data. Upon request, exida-certified FMEDA data is provided to be used by a functional safety practitioner to determine the SST’s and SSX’s applicability in specific safety-related applications.

- Valuable HART data not lost. Both the SSX and SST pass critical HART data to asset management systems, programming devices or host systems.

- Split signals between two locations. The 4-Wire SST takes in one signal and gives you two fully isolated outputs that can be taken to two separate receiving devices. This facilitates maintenance on either output loop without losing the signal on the other output loop.

- RFI/EMI Protection. Standard 20V/m protection offered to protect against harmful effects of radio frequency and electromagnetic interference.

- Transmitter excitation. The 4-wire SST is capable of providing loop power to a 2-wire transmitter that is connected to its input.

Moore Industries’ universal PSD PC-Programmable Loop Display features a large integral display that shows real-time process status in mA, percent, or any designated 5-character Engineering units (EGU). Superior Accuracy–The loop-powered PSD reads any 4-20mA signal and displays the information with phenomenal accuracy of ±0.012% of input scale. And because it requires less than 2.3 Volts, it won’t burden most loops. Simple and Versatile PC Setup Program– Using the PC software, the PSD can either be custom scaled to display in a percent or scaled directly into engineering units for indicating process measurements such as pressure, temperature, level, or fl ow. Span, zero, input range, display range, and fi ltering frequency can also be easily programmed. Our software will even capture the input range limits of the loop to provide you with the most accurate display available

Moore Industries’ universal PSD PC-Programmable Loop Display features a large integral display that shows real-time process status in mA, percent, or any designated 5-character Engineering units (EGU). Superior Accuracy–The loop-powered PSD reads any 4-20mA signal and displays the information with phenomenal accuracy of ±0.012% of input scale. And because it requires less than 2.3 Volts, it won’t burden most loops. Simple and Versatile PC Setup Program– Using the PC software, the PSD can either be custom scaled to display in a percent or scaled directly into engineering units for indicating process measurements such as pressure, temperature, level, or fl ow. Span, zero, input range, display range, and fi ltering frequency can also be easily programmed. Our software will even capture the input range limits of the loop to provide you with the most accurate display available

CX Screwplug Immersion Heater is used primarily to heat water in tanks through natural convection currents. Typical heaters have standard 1" - 2 1/2" NPT tapered plugs. Other sizes or plugs are available on special order.

CX Screwplug Immersion Heater is used primarily to heat water in tanks through natural convection currents. Typical heaters have standard 1" - 2 1/2" NPT tapered plugs. Other sizes or plugs are available on special order.

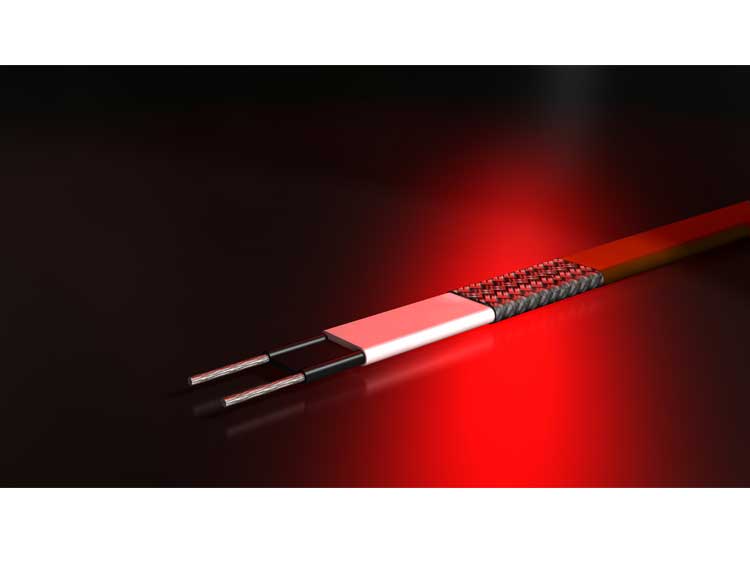

Self-regulating heating cables consist of two parallel bus wires embedded in a networked plastic heating element, doped with surrounding carbon particles. If the temperature increases during operation, the plastic expands due to molecular expansion and the distance between the carbon particles increases. Resistance increases and output drops. When it cools down, this process is reversed and output increases.

This physical property provides several benefits, including the ability to overlap the self-regulating cable and installation without the requirement of a temperature cut-out device.

Benefits:

Self-regulating heating cables consist of two parallel bus wires embedded in a networked plastic heating element, doped with surrounding carbon particles. If the temperature increases during operation, the plastic expands due to molecular expansion and the distance between the carbon particles increases. Resistance increases and output drops. When it cools down, this process is reversed and output increases.

This physical property provides several benefits, including the ability to overlap the self-regulating cable and installation without the requirement of a temperature cut-out device.

Benefits:

Series 100P (diaphragm sensor) for pneumatic and low impulse hydraulics up to 3000 psig system pressure

Versatile Nega-Rate® Belleville disc spring pressure switch for a wide range of applications.

Specifications

• Electrical: Snap action electrical switch recognized by Underwriters’ Laboratories, Inc. and CSA International

• Electrical Connection: 1/2 NPT female conduit connection with terminal block

• Pressure Connection:

o Wetted Material 1 1/4 NPT Female

o Wetted Material 4, 5, 7 and 9 1/2 NPT Female

• Temperature Range

o Ambient: -40°F to +180°F (-40°C to +82°C)

o Media: -40°F to +300°F (-40°C to +149°C)

• Media temperature limits change with O-Ring selection

• Adjustment: Concealed wrench flat adjustment with range scale

• Shipping Weight: Approximately 3 pounds

Series 100P (diaphragm sensor) for pneumatic and low impulse hydraulics up to 3000 psig system pressure

Versatile Nega-Rate® Belleville disc spring pressure switch for a wide range of applications.

Specifications

• Electrical: Snap action electrical switch recognized by Underwriters’ Laboratories, Inc. and CSA International

• Electrical Connection: 1/2 NPT female conduit connection with terminal block

• Pressure Connection:

o Wetted Material 1 1/4 NPT Female

o Wetted Material 4, 5, 7 and 9 1/2 NPT Female

• Temperature Range

o Ambient: -40°F to +180°F (-40°C to +82°C)

o Media: -40°F to +300°F (-40°C to +149°C)

• Media temperature limits change with O-Ring selection

• Adjustment: Concealed wrench flat adjustment with range scale

• Shipping Weight: Approximately 3 pounds

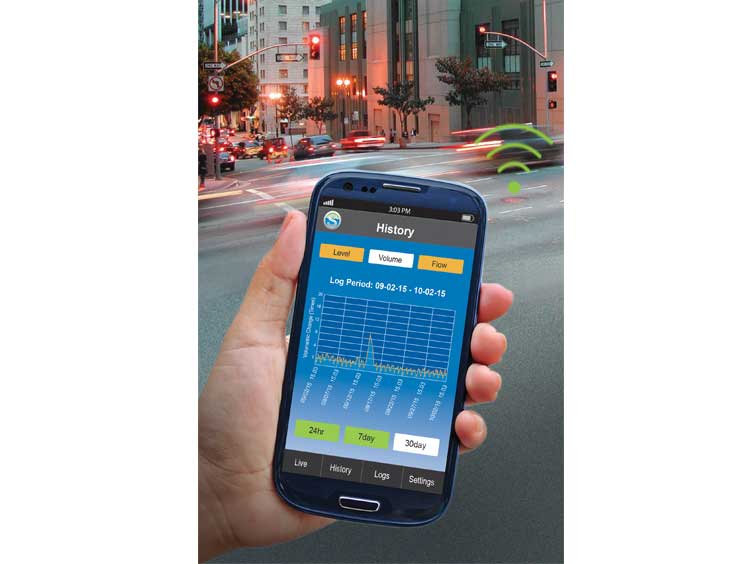

SewerWatch the First Mobile App for Wastewater Infrastructure

SewerWatch the First Mobile App for Wastewater Infrastructure

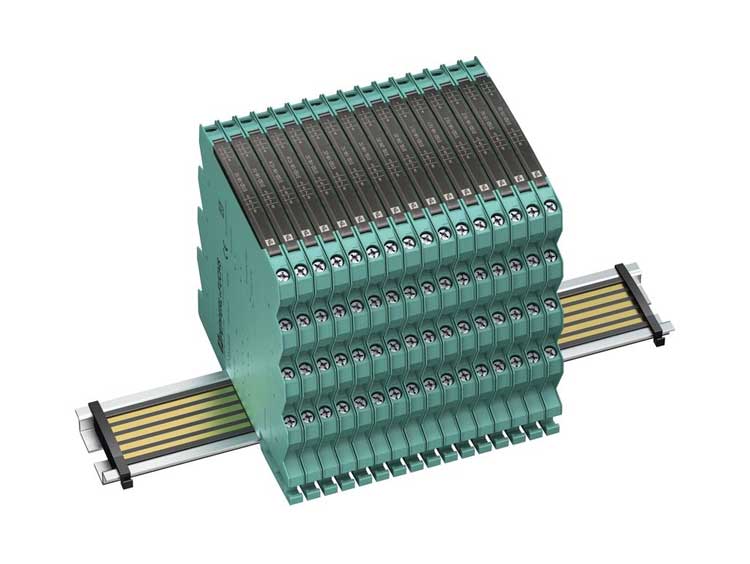

The K-system comprises signal conditioners for signal transfer between control system and safe area as well as isolated barriers for communication with field devices in hazardous areas. They are preferred for these kinds of mixed applications. Wide range of isolated barriers and signal conditioners for mixed applications

Modules for universal power supply

Reduced wiring by Power Rail

Removable terminals

Many modules with marine approvals and SIL assessment

The K-system comprises signal conditioners for signal transfer between control system and safe area as well as isolated barriers for communication with field devices in hazardous areas. They are preferred for these kinds of mixed applications. Wide range of isolated barriers and signal conditioners for mixed applications

Modules for universal power supply

Reduced wiring by Power Rail

Removable terminals

Many modules with marine approvals and SIL assessment

SV SERIES STABILIZED CONNECTORS WITH INTEGRAL VALVE

NOSHOK STABILIZED CONNECTORS WITH INTEGRAL VALVE are also designed to reinforce an installation by shifting radial-stress load away from the NPT connections, but also feature a block valve that can be installed on either side of stabilized body, allowing 1/2 turn installation. SV Series Stabilized Connectors with Integral Valve are available in zincnickel plated carbon steel and 316 stainless steel, and feature slotted bolt holes that allow for 2-1/8" and 2-1/4" bolt spacings.The integral valve has a 0.375" bore for unrestricted passage of process gas, and a standard non-rotating stem tip. This application will work on both flat surfaces (orifice fitting) and round surfaces (orifice flange) with flange adaptor. A single piece dielectric gasket (DK1) is available as an option to create a non-conductive shield between the process piping and the instrument. A two piece dielectric kit (DK2) is also available as an alternative when a separate sealing gasket or o-ring is required. Stainless steel bolts are also available.

SV SERIES STABILIZED CONNECTORS WITH INTEGRAL VALVE

NOSHOK STABILIZED CONNECTORS WITH INTEGRAL VALVE are also designed to reinforce an installation by shifting radial-stress load away from the NPT connections, but also feature a block valve that can be installed on either side of stabilized body, allowing 1/2 turn installation. SV Series Stabilized Connectors with Integral Valve are available in zincnickel plated carbon steel and 316 stainless steel, and feature slotted bolt holes that allow for 2-1/8" and 2-1/4" bolt spacings.The integral valve has a 0.375" bore for unrestricted passage of process gas, and a standard non-rotating stem tip. This application will work on both flat surfaces (orifice fitting) and round surfaces (orifice flange) with flange adaptor. A single piece dielectric gasket (DK1) is available as an option to create a non-conductive shield between the process piping and the instrument. A two piece dielectric kit (DK2) is also available as an alternative when a separate sealing gasket or o-ring is required. Stainless steel bolts are also available.