The F193 is a versatile large digit Modbus display. All displayed information and signal outputs are controlled through the Modbus ASCII / RTU communication protocol. Information of nine different tanks or products can be displayed with an automatic toggle function or can be selected by the operator. Of course, it can also be selected and locked through communication.

Further, up to four control or alarm outputs can be controlled directly or being linked to an alarm status of the nine products: an alarm message will be displayed and the related relay(s) switched. Also available is an analog output signal, fully controlled through the communication. For security reasons, all outputs can be switched-off automatically in case of a communication break-down.

The display shows the actual value, product / tank ID, measuring unit, alarm messages and status.

The F010 is a local weather-proof indicator with large 26mm (1”) high digits which displays the actual flow rate. The measuring and time unit to be displayed below the flow rate are simply selected through an alphanumeric configuration menu. The configuration of K-factors or Span and number of decimals is done through software functions without any sensitive DIP-switches or trimmers.

The F010 is a local weather-proof indicator with large 26mm (1”) high digits which displays the actual flow rate. The measuring and time unit to be displayed below the flow rate are simply selected through an alphanumeric configuration menu. The configuration of K-factors or Span and number of decimals is done through software functions without any sensitive DIP-switches or trimmers.

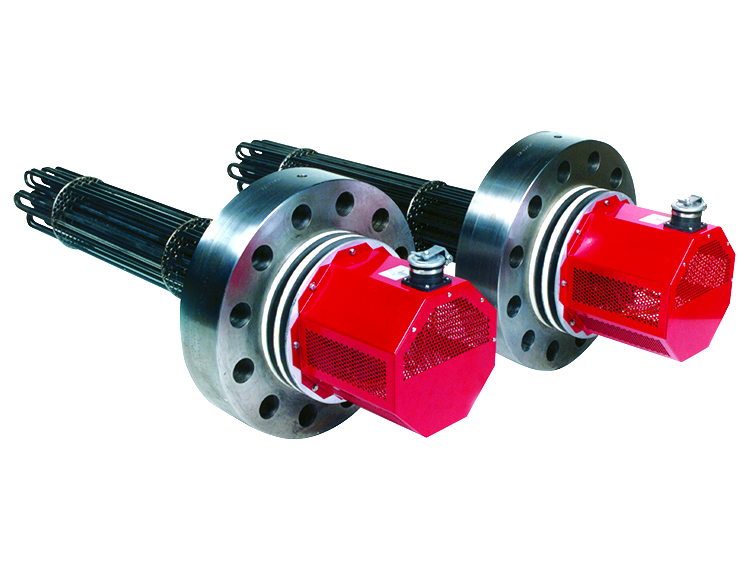

CXC Flange Heaters are used primarily for water heating applications and feature copper sheathed elements silver brazed to a steel flange.

CXI Flange Heaters are well suited for heating water, especially in hot water and steam boilers, as well as heating mildly corrosive solutions in rinse tanks, spray washers, etc. The heater features incoloy® sheathed elements silver brazed to steel flange.

CXF Flange Heaters are used primarily for heating applications involving oils, gases and mildly corrosive liquids. They are constructed of incoloy® sheathed elements silver brazed to a steel flange.

CXC Flange Heaters are used primarily for water heating applications and feature copper sheathed elements silver brazed to a steel flange.

CXI Flange Heaters are well suited for heating water, especially in hot water and steam boilers, as well as heating mildly corrosive solutions in rinse tanks, spray washers, etc. The heater features incoloy® sheathed elements silver brazed to steel flange.

CXF Flange Heaters are used primarily for heating applications involving oils, gases and mildly corrosive liquids. They are constructed of incoloy® sheathed elements silver brazed to a steel flange.

FMS Series electromagnetic flow meter easily connects too many common controllers.

Economical small-diameter flow sensors for reliable full-pipe flow measurement with low-cost and fast installation.

FMS05 / FMS10 / FMS20 FEATURES

• Accuracy to +/-2.0%

• Flows from 0.5 to 951 GPH

• Pressures to 145 PSI

• Fluid temperatures to 140 F

• Compatible with pulsating flows

• Easy to install union end connections

• Outputs: Pulse, Error, Alarm.

FMS Series electromagnetic flow meter easily connects too many common controllers.

Economical small-diameter flow sensors for reliable full-pipe flow measurement with low-cost and fast installation.

FMS05 / FMS10 / FMS20 FEATURES

• Accuracy to +/-2.0%

• Flows from 0.5 to 951 GPH

• Pressures to 145 PSI

• Fluid temperatures to 140 F

• Compatible with pulsating flows

• Easy to install union end connections

• Outputs: Pulse, Error, Alarm.

The E/One Gas Station is a modular approach that combines monitoring and control systems onto a single skid, customized to meet specific power plant requirements and budgets. Gas Station modules include:

• Main gas supply manifold and associated controls

• Gas purity monitoring

• Overheat monitoring

• Dew point monitoring

• Gas drying

• Partial discharge monitoring

• Seal oil system monitoring and control

• Customized annunciator panels

The E/One Gas Station is a modular approach that combines monitoring and control systems onto a single skid, customized to meet specific power plant requirements and budgets. Gas Station modules include:

• Main gas supply manifold and associated controls

• Gas purity monitoring

• Overheat monitoring

• Dew point monitoring

• Gas drying

• Partial discharge monitoring

• Seal oil system monitoring and control

• Customized annunciator panels