Skip to content

-

PRE-ENGINEERED CHEMICAL METERING SYSTEMS

Pre-Packaged & Self-Contained Chemical Feed Systems

Features:

- Suitable for base or wall mounting

- Flow rates to 25 GPH, pressures to 150 PSI

- Flow Monitor provides audible & visual indication upon loss of flow

- Relay output can start back-up pump and/or signal an operator remotely via an autodialer

- Integral leak containment with optional level alarm

-

New low-cost, compact version of our ISOMAG electromagnetic flow meters. Designed to be easily incorporated into equipment or machinery.

Features:

- Small electromagnetic flow meter with integrated display

- Suitable for flow measurement in liquids with a minimum conductivity of 20 µS/cm

- Measuring accuracy ± 1% of reading

- Housing in Noryl reinforced with 30% fiberglass

- Protection rating NEMA 6 (IP 67)

- Max liquid temperature 185°F

- Power supply 18-30 VDC

- Digital and analog outputs can be configured via PC, using dedicated MCP software

Applications:

- Replacement of mechanical meters

- Solvent Dispensers

- Flow Control for water-soluble coolant

- Sampling systems

- Dosing of additives in concrete

- Water distribution for industrial cooking, washing machines

- Control of consumption

- Wood treatment

- Control in cooling systems for welding, laser machines, robots or metal manufacturing

- Machine Tools

-

ISOMAG CS3795 Insertion Electromagnetic Flowmeter Combines reliable full-pipe flow measurement with low-cost, compact size and ease of installation.

Features:

- Integral converter

- 18-30VDC

- Pulse or 4-20mA output

- Accuracy to +/-2%

- Three sizes for up to 80" Pipe Diameters

- Pressures to 235 PSI

- Can be removed and reinstalled in non-pressurized lines

- Volumetric flow rate measurement independent of fluid viscosity, density and temperature

- No moving parts for zero maintenance

- Bi-directional flow measurement

- Every sensor is factory wet-calibrated

-

MV800 Ultra compact electromagnetic flow meter converter suitable for connection to full-bore ISOMAG® sensors up to 16

Features:

- Ultra compact converter suitable for connection to ISOMAG ® MS1000 or MS2500 sensors up to 16 inches

- Suitable for flow measurement of liquids with a minimum conductivity of 20 µS/cm

- Measuring accuracy +/- 0.5% of reading

- Cast aluminum or 304 SS housing

- Nema 6 (IP 67) protection rating

- Power supply 10 - 30 VDC @1W, electrical connections via 5-pin connector

- Up to two digital pulse outputs and/or 4-20mA outputs available

- PC programming via USB cable and dedicated software (MCP Protocol)

- No moving parts

- Bi-directional flow measurement

- Every sensor is factory wet calibrated and tested

-

Perfect for tank level measurement and control

The FLOMOTION LM7000 provides non-contacting level measurement for a wide variety of applications in both liquids and solids. The system is composed of an ultrasonic sensor and a remote mounted controller for maximum flexibility.

Easy calibration and maintenance-free performance means you can install the LM7000 rapidly and with confidence.

Features:

- Measurement range 33 ft (S330 sensor) or 50 ft (S500 sensor)

- Programmable 4-20mA analog output

- Menu driven programming

- 4-20mA and relay outputs

- 3 or 6 SPDT relays for alarms and external control

- Sensor is weather resistant and safe against submersion (NEMA 6P)

- Automatic temperature compensation

- Datalogging

- Single or Dual Sensor

-

The LT330 Series is designed to measure liquid level in a wide variety of applications.

The compact, loop-powered LT330 provides continuous, non-contacting level measurement. Up to 33ft (10m) range.

The large LCD display, 4 status lights and 5 button keypad make setup and operation quick and easy.

Features:

The LT330 Series is designed to measure liquid level in a wide variety of applications.

The compact, loop-powered LT330 provides continuous, non-contacting level measurement. Up to 33ft (10m) range.

The large LCD display, 4 status lights and 5 button keypad make setup and operation quick and easy.

Features:

- 33ft (10m) range

- Accuracy of 0.2% with 1mm resolution

- Easy to install 2” NPT fitting

- Loop powered 4-20mA (max 750 Ω)

- 5 digit numeric LCD display

- Integral 5 button keypad

- 4 status lights

- Built-in temperature compensation sensor

Applications:

- Bulk Chemical Storage

- Pump Stations

- Clarifiers

- Filtration Levels

- River Level Monitoring

- Trash Rack Level Monitoring

- Waste Sump

- Tanker Truck Filling

- Water Storage Towers

- Reactors

-

The LT260 Series is designed to measure liquid level in a wide variety of applications.

The compact, loop-powered LT260 provides continuous, non-contacting level measurement. With a measuring range of 26ft (8m) the LT260 will accommodate a wide range of applications.

The large LCD display, 4 status lights and 5 button keypad make setup and operation quick and easy.

Features:

The LT260 Series is designed to measure liquid level in a wide variety of applications.

The compact, loop-powered LT260 provides continuous, non-contacting level measurement. With a measuring range of 26ft (8m) the LT260 will accommodate a wide range of applications.

The large LCD display, 4 status lights and 5 button keypad make setup and operation quick and easy.

Features:

- Low Cost

- High Accuracy

- Non-Contact Measurement

- No Moving Parts

- Compact, Lightweight Design

- Corrosion Resistant Materials

- Built-in Temperature Compensation

- Programmable 4-20mA Output

- Selectable Transducer Power Level

- Adjustable Damping

- Displays Level, Distance or Space

- Loss of Echo Indicator

- Interface this level sensor with the FLOMOTION DR5000 Chart Recorder

Applications:

- Bulk Chemical Storage

- Pump Stations

- Clarifiers

- Filtration Levels

- River Level Monitoring

- Trash Rack Level Monitoring

- Waste Sump

- Tanker Truck Filling

- Water Storage Towers

- Reactors

-

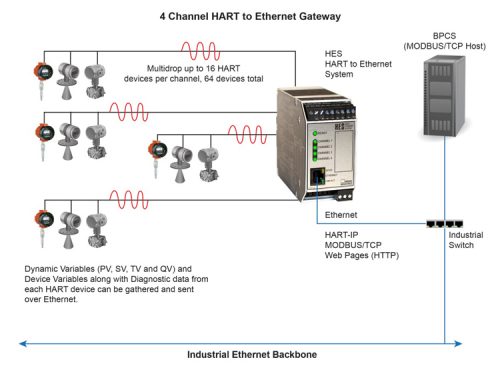

HES HART to Ethernet Gateway System converts signals from wired HART devices to Ethernet MODBUS/TCP and HART-IP

Timely knowledge about your process enables better decisions and faster preventive action. Now you can get the process detail that you need from your Smart HART devices to MODBUS/TCP and HART-IP based monitoring and control systems at the speed of Ethernet with the HES HART to Ethernet Gateway System.

Connect up to 64 Smart HART devices to the HES and collect the Dynamic Variables and the Device Variables, along with diagnostic bits and bytes, from each device that helps deliver critical information needed to help you address process and device problems before they turn into unplanned downtime.

Moore Industries’ rugged HES supports HART 5, 6 and 7 devices with sufficient memory to handle thousands of process variables, and diagnostic data points from up to 64 connected smart HART devices.

The HES allows you to further leverage your industrial Ethernet investment by making all of this valuable HART data viewable with any web browser or MODBUS/TCP compliant host.

Support for these open industrial protocols enables you to easily interface with any process control or asset management system while taking advantage of any Industrial Internet of Things (IIoT) initiatives that facilitate the propagation of process data to higher level corporate or analytical systems.

-

Standard Features:

- 2" (50.80mm) and larger

- Process Connection Sizes 2" and 3"

- Maximum Working Pressure Conforms to Flange Pressure-Temperature Ratings per ASME/ANSI B16.5

- Flange Faces (125-250Ra Spiral Finish is standard)

- Raised Face , Flat Face , Ring Type Joint and Special Flange Faces are available

-

Standard Features:

- Standard Pressure Rating with Metal Lower Housing

- Process Connection Sizes 1/4 " NPTF through 1 1/2" NPTF

- Maximum Pressure Rating 750, 1500 PSIG (5,18,10.35Mpa) @ 100ºF (38ºC)

-

Standard Features:

- 3" (76.20mm) 150# and 3" (76.20mm) 300lb

- Process Connection Sizes 3" ASME/ANSI Flange Ratings 150# and 300# ... other flange ratings available

- Maximum Working Pressure Conforms to Flange Pressure-Temperature Ratings per ASME/ANSI B16.5

- Flange Faces, Raised Face and Flat Face

-

Standard Features:

- 2" (50.80mm) and Larger

- Process Connection Sizes 2" through 3" ASME/ANSI Flange Rating up to 2500lb

- Maximum Working Pressure Conforms to Flange Pressure-Temperature Ratings per ASME/ANSI B16.5

- Flange Faces (125-250Ra Spiral Finish is standard)

- Raised Face , Flat Face , Ring Type Joint and Special Flange Faces are available

Page load link