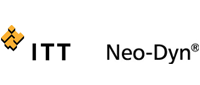

STA SIL 2 and SIL 3 Compliant Programmable Current/Voltage and RTD/Thermocouple Safety Trip Alarms

The exida® SIL 2 and SIL 3 certified STA Safety Trip Alarm performs as a logic solver and acts on potentially hazardous process conditions; warns of unwanted process conditions; provides emergency shutdown; or provides on/off control in Safety Instrumented Systems (SIS) and traditional alarm trip applications. The 4-wire (line/mains-powered) STA models accept a signal input from transmitters, temperature sensors and a wide array of other monitoring and control instruments including:Current and Voltage Signals Temperature (RTD and T/C) Sensor Inputs Resistance and Potentiometer Devices Direct Millivolt Sources

Features:

- exida certified IEC 61508:2010. For systematic integrity up to SIL 3 and for random integrity up to SIL 2. This means that an STA is approved for single use in Safety Instrumented Systems (SIS) up to SIL 2 and in redundant architectures (1oo2, 2oo3, etc.) up to SIL 3.

- Comprehensive FMEDA certified safety data. Upon request, exida-certified FMEDA (Failure Modes, Effects and Diagnostics Analysis) data is provided to be used by a competent functional safety practitioner to determine the STA’s applicability as a logic solver in specific safety-related applications.

- 20-bit input resolution with long-term stability. Delivers industry-best digital accuracy with up to 5 years between scheduled calibrations.

- Site-programmable with password protection. Front panel pushbuttons with menu-guided configuration deliver confident and secure set up.

- Large 5-digit process and status readout. Backlit display shows menu prompts during configuration and, when in operation, shows the process variable, the output or toggles between the two in selectable engineering units.

- Isolated and RFI/EMI protection. Delivers superior protection against the effects of ground loops and plant noise.

- Combined alarm trip and transmitter. The analog output (-AO) option reduces costs and installation time when both alarm and transmitter functions are needed at the same location.

WXH & WXL Process Duct Heaters are designed for installation in process ducts to heat air or other non-hazardous gases. Installation can be in any position: top, bottom, or side mounting. The heater is inserted into a duct through a hole and secured with suitable bolts, studs or screws.

WXH & WXL Process Duct Heaters are designed for installation in process ducts to heat air or other non-hazardous gases. Installation can be in any position: top, bottom, or side mounting. The heater is inserted into a duct through a hole and secured with suitable bolts, studs or screws.

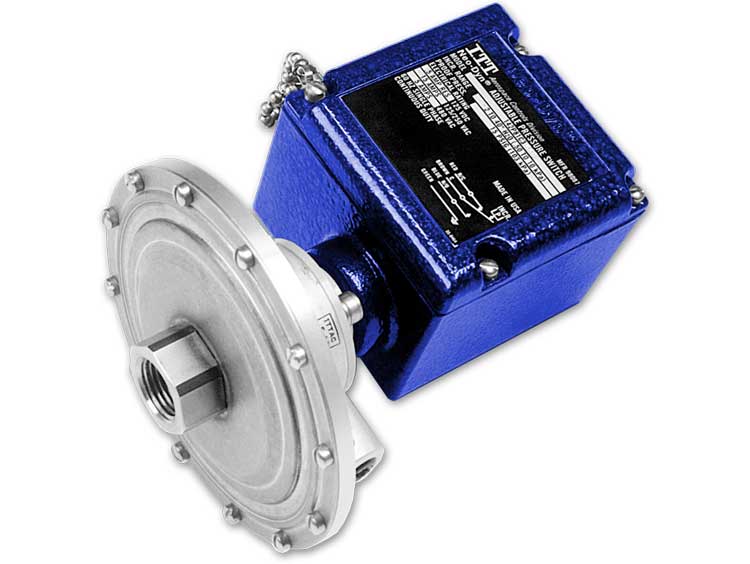

Series 200P NEMA 4 & 13 Pressure Switch/Internal Adjustment

Versatile Nega-Rate® Belleville disc spring pressure switch for a wide range of applications. Series 200P (piston sensor) for hydraulic applications up to 10000 psig system pressure.

Specifications

• Electrical: Snap action electrical switch recognized by Underwriters’ Laboratories, Inc. and CSA International

• Electrical Connection: 1/2 NPT female conduit connection with terminal block

• Pressure Connection: Wetted Material 1 1/4 NPT Female

• Temperature Range*:

o Ambient: -40°F to +180°F (-40°C to +82°C)

o Media: -40°F to +300°F (-40°C to +149°C)

*Temperature limits change with O-Ring selection

• Adjustment: Concealed wrench flat adjustment with range scale

• Shipping Weight: Approximately 3 pounds

Series 200P NEMA 4 & 13 Pressure Switch/Internal Adjustment

Versatile Nega-Rate® Belleville disc spring pressure switch for a wide range of applications. Series 200P (piston sensor) for hydraulic applications up to 10000 psig system pressure.

Specifications

• Electrical: Snap action electrical switch recognized by Underwriters’ Laboratories, Inc. and CSA International

• Electrical Connection: 1/2 NPT female conduit connection with terminal block

• Pressure Connection: Wetted Material 1 1/4 NPT Female

• Temperature Range*:

o Ambient: -40°F to +180°F (-40°C to +82°C)

o Media: -40°F to +300°F (-40°C to +149°C)

*Temperature limits change with O-Ring selection

• Adjustment: Concealed wrench flat adjustment with range scale

• Shipping Weight: Approximately 3 pounds

Terminal Junction Boxes Glass Fiber Reinforced Polyester (GRP) GL***.T

Glass fiber reinforced polyester (GRP) enclosure

Ex e, Ex ia and Ex tb certified

16 enclosure size options

Customizable configuration of terminals, cable entries and cable gland types as per specification

Installation in Zone 1, Zone 2, Zone 21 and Zone 22

Wide range of accessories available

Terminal Junction Boxes Glass Fiber Reinforced Polyester (GRP) GL***.T

Glass fiber reinforced polyester (GRP) enclosure

Ex e, Ex ia and Ex tb certified

16 enclosure size options

Customizable configuration of terminals, cable entries and cable gland types as per specification

Installation in Zone 1, Zone 2, Zone 21 and Zone 22

Wide range of accessories available

The MS1000 Magnetic Flow Meter

Features

• Accuracy to +/-0.2%

• Lower cost than flanged units.

• Twelve sizes from 1/2" to 16" Pipe Diameters.

• Flow ranges from 0.85 to 19,934 GPM.

• Standard Pressure: 230 PSI.

• Volumetric flow rate measurement independent of fluid viscosity, density and temperature.

• No moving parts for zero maintenance.

• Bi-directional flow measurement.

• No pressure drop through sensor.

• Optional Integral ground electrode eliminates grounding rings with plastic piping systems.

• Minimal straight pipe run required.

• Every sensor is factory wet-calibrated.

The MS1000 Magnetic Flow Meter

Features

• Accuracy to +/-0.2%

• Lower cost than flanged units.

• Twelve sizes from 1/2" to 16" Pipe Diameters.

• Flow ranges from 0.85 to 19,934 GPM.

• Standard Pressure: 230 PSI.

• Volumetric flow rate measurement independent of fluid viscosity, density and temperature.

• No moving parts for zero maintenance.

• Bi-directional flow measurement.

• No pressure drop through sensor.

• Optional Integral ground electrode eliminates grounding rings with plastic piping systems.

• Minimal straight pipe run required.

• Every sensor is factory wet-calibrated.

The F193 is a versatile large digit Modbus display. All displayed information and signal outputs are controlled through the Modbus ASCII / RTU communication protocol. Information of nine different tanks or products can be displayed with an automatic toggle function or can be selected by the operator. Of course, it can also be selected and locked through communication.

Further, up to four control or alarm outputs can be controlled directly or being linked to an alarm status of the nine products: an alarm message will be displayed and the related relay(s) switched. Also available is an analog output signal, fully controlled through the communication. For security reasons, all outputs can be switched-off automatically in case of a communication break-down.

The display shows the actual value, product / tank ID, measuring unit, alarm messages and status.

The F193 is a versatile large digit Modbus display. All displayed information and signal outputs are controlled through the Modbus ASCII / RTU communication protocol. Information of nine different tanks or products can be displayed with an automatic toggle function or can be selected by the operator. Of course, it can also be selected and locked through communication.

Further, up to four control or alarm outputs can be controlled directly or being linked to an alarm status of the nine products: an alarm message will be displayed and the related relay(s) switched. Also available is an analog output signal, fully controlled through the communication. For security reasons, all outputs can be switched-off automatically in case of a communication break-down.

The display shows the actual value, product / tank ID, measuring unit, alarm messages and status.