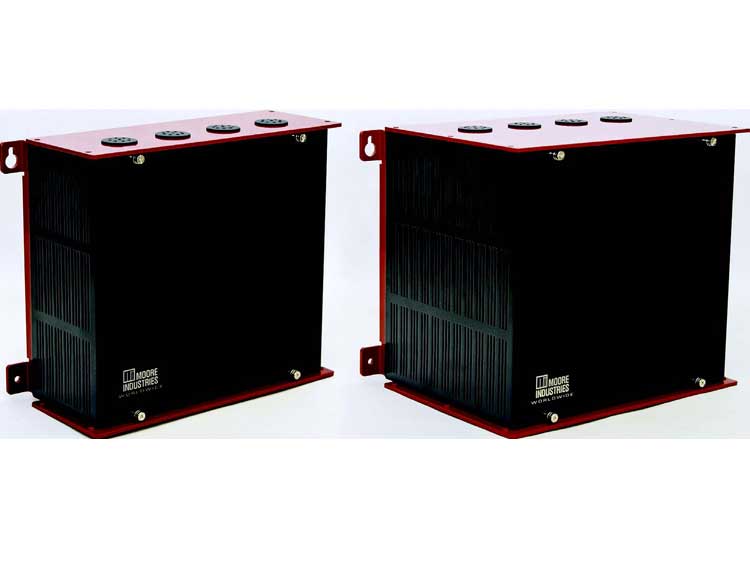

HIT/HIX HART® Isolators provide highly economical solutions to common and costly problems that plague many of today’s “smart” process loops. Protect and enhance your HART investment with the 2-wire (loop powered) HIX or the 4-wire (line-mains powered) HIT.

Download Data Sheet

HIT/HIX HART® Isolators provide highly economical solutions to common and costly problems that plague many of today’s “smart” process loops. Protect and enhance your HART investment with the 2-wire (loop powered) HIX or the 4-wire (line-mains powered) HIT.

Download Data Sheet -

The Conoflow HP300 High Pressure Regulator is designed to accurately control supply pressures up to 10,000 PSIG (69 MPa). This piston sensing, self-relieving regulator allows pressure setting reduction in a closed system by relieving downstream pressure through the regulator.For hazardous media applications a non-relieving piston is offered. Where noncorrosive media are present, the HP300 Regulator is offered in both brass and stainless steel constructions. N.A.C.E. models are rated for a maximum supply pressure up to 6,000 PSIG (41.4 MPa). Each unit is supplied with 1/4" inlet, outlet and two gauge ports. CGA cylinder connections are also available.The HP300 Regulator provides excellent sensitivity through six control setting ranges: 8-500, 9-800, 10-1500, 15-2500, 25-4000, and 30-6000 PSIG (0.06-3.45, 0.062-5.52, 0.069-10.35, 0.104-17.25, 0.173-27.60, and 0.207-41.40 MPa). All of these regulated pressure ranges can be obtained from one regulator simply by interchanging range/sensor kits. Adjustment within each range is made by a large handwheel (standard) or by an optional "T" bar handle.Designed for reliability with minimum maintenance, this unit is commonly used for instrument calibration, for corrosive gases, airline charging systems, cylinder gas regulation, process sampling systems, cylinder filling stations and other applications where rugged construction and accurate control of high pressure is required.

The Conoflow HP300 High Pressure Regulator is designed to accurately control supply pressures up to 10,000 PSIG (69 MPa). This piston sensing, self-relieving regulator allows pressure setting reduction in a closed system by relieving downstream pressure through the regulator.For hazardous media applications a non-relieving piston is offered. Where noncorrosive media are present, the HP300 Regulator is offered in both brass and stainless steel constructions. N.A.C.E. models are rated for a maximum supply pressure up to 6,000 PSIG (41.4 MPa). Each unit is supplied with 1/4" inlet, outlet and two gauge ports. CGA cylinder connections are also available.The HP300 Regulator provides excellent sensitivity through six control setting ranges: 8-500, 9-800, 10-1500, 15-2500, 25-4000, and 30-6000 PSIG (0.06-3.45, 0.062-5.52, 0.069-10.35, 0.104-17.25, 0.173-27.60, and 0.207-41.40 MPa). All of these regulated pressure ranges can be obtained from one regulator simply by interchanging range/sensor kits. Adjustment within each range is made by a large handwheel (standard) or by an optional "T" bar handle.Designed for reliability with minimum maintenance, this unit is commonly used for instrument calibration, for corrosive gases, airline charging systems, cylinder gas regulation, process sampling systems, cylinder filling stations and other applications where rugged construction and accurate control of high pressure is required. -

Conoflow's HP400 is a piston-sensing, self-contained pressure reducing regulator. High inlet and outlet pressures allow use of this regulator in component testing, calibration systems, manufacturing processes and other applications that require an economical regulator having reliable and safe operating characteristics.The brass constructed HP400 Regulator has a maximum supply pressure rating of 3500 PSIG (24.2 MPa). Control setting range for this unit is 20 to 2500 PSIG (0.138 -17.25 MPa). Adjustments within the range are made with a large handwheel furnished with the standard unit. Optional adjustment devices include a wrench style knob with a locking device or a "T" bar handle.This unit is supplied with 1/4" NPT inlet and outlet connections. Inlet and outlet gauge ports (1/4" NPT) are standard. The regulator is non-relieving with a captured bonnet.

Conoflow's HP400 is a piston-sensing, self-contained pressure reducing regulator. High inlet and outlet pressures allow use of this regulator in component testing, calibration systems, manufacturing processes and other applications that require an economical regulator having reliable and safe operating characteristics.The brass constructed HP400 Regulator has a maximum supply pressure rating of 3500 PSIG (24.2 MPa). Control setting range for this unit is 20 to 2500 PSIG (0.138 -17.25 MPa). Adjustments within the range are made with a large handwheel furnished with the standard unit. Optional adjustment devices include a wrench style knob with a locking device or a "T" bar handle.This unit is supplied with 1/4" NPT inlet and outlet connections. Inlet and outlet gauge ports (1/4" NPT) are standard. The regulator is non-relieving with a captured bonnet. -

The HP500 Regulator is a self-contained, diaphragm sensing high purity regulator. A broad offering of materials of construction and five control pressure ranges allow use of this unit in applications that include the regulating of specialty gases, gas chromatography, research labs as well as the regulation of corrosive and noncorrosive gases and liquids.Material options include brass, 316 stainless steel and 316L stainless steel. N.A.C.E., monel and hastelloy constructions are available upon request. The brass units are rated for a maximum supply pressure of 5,000 PSIG (34.5 MPa) and the stainless steel units are rated to 6,000 PSIG (41.4 MPa). Optional 15 Ra microinch wetted surfaces are available.This high purity, pressure regulator is designed to accurately control pressure ranges of 4-25, 4-50, 5-100, 6-250, and 10-500 PSIG (0-0.173, 0-0.345, 0-0.690, 0-1.73, and 0-3.45 MPa). The HP500 has 1/4" NPT inlet and outlet connections. Gauge ports are optional. To suit high purity applications, Vacuseal, VCR and Ultra Seal welded fittings are available. Adjustments within each range are made with a standard large handwheel.A wrench style knob with a locking device and a "T" bar handle are optional adjustments.

The HP500 Regulator is a self-contained, diaphragm sensing high purity regulator. A broad offering of materials of construction and five control pressure ranges allow use of this unit in applications that include the regulating of specialty gases, gas chromatography, research labs as well as the regulation of corrosive and noncorrosive gases and liquids.Material options include brass, 316 stainless steel and 316L stainless steel. N.A.C.E., monel and hastelloy constructions are available upon request. The brass units are rated for a maximum supply pressure of 5,000 PSIG (34.5 MPa) and the stainless steel units are rated to 6,000 PSIG (41.4 MPa). Optional 15 Ra microinch wetted surfaces are available.This high purity, pressure regulator is designed to accurately control pressure ranges of 4-25, 4-50, 5-100, 6-250, and 10-500 PSIG (0-0.173, 0-0.345, 0-0.690, 0-1.73, and 0-3.45 MPa). The HP500 has 1/4" NPT inlet and outlet connections. Gauge ports are optional. To suit high purity applications, Vacuseal, VCR and Ultra Seal welded fittings are available. Adjustments within each range are made with a standard large handwheel.A wrench style knob with a locking device and a "T" bar handle are optional adjustments. -

ITT Conoflow’s HP610 is a high purity, self-contained, spring-loaded, pressure reducing regulator. This unit is designed for use in applications requiring high flow rates and the ability to relieve outlet media pressure. Non-relieving models are also available.The 316 Stainless Steel constructed unit has a maximum supply pressure rating to 250 PSIG (1.73 MPa). The convoluted 316 Stainless Steel diaphragm provides accurate and reliable regulation over a control setting range of 0 - 50 PSIG (0 - 0.35 MPa).The HP610 has one ¼” NPT inlet connection and two ¼” NPT outlet connections. Both outlet ports provide the same flow capacity with the central port generally being used as a gauge port.

ITT Conoflow’s HP610 is a high purity, self-contained, spring-loaded, pressure reducing regulator. This unit is designed for use in applications requiring high flow rates and the ability to relieve outlet media pressure. Non-relieving models are also available.The 316 Stainless Steel constructed unit has a maximum supply pressure rating to 250 PSIG (1.73 MPa). The convoluted 316 Stainless Steel diaphragm provides accurate and reliable regulation over a control setting range of 0 - 50 PSIG (0 - 0.35 MPa).The HP610 has one ¼” NPT inlet connection and two ¼” NPT outlet connections. Both outlet ports provide the same flow capacity with the central port generally being used as a gauge port. -

ITT Conoflow’s HP635 Series unit is a high-flow, high-purity regulator that is designed as a purge gas regulator and may be used in high purity gas systems involving corrosive and toxic media. All wetted components are of a 316 Stainless Steel construction having a maximum 35Ra surface finish. An optional brass model (NPT port only) is available for inert gas service.This unit has a large main valve providing a flow capacity of Cv=1.8 at the valve. Connections are 1/2” NPT or 1/2” Tube Stubs with either style having a maximum supply pressure rating of 500 psig. Outlet pressure ranges of 0-25, 0-50, 0-100, 0-150 and 0-200 psig (0-0.173, 0-0.345, 0-0.69, 0-1.04, and 0-138 MPa) are available. The HP635 Regulator is offered with an inboard and across the seat leakage specification of 2 x 10-8 atm. cc/sec Helium. Also, there is an adjustable stop that may be set to limit pressure control settings for specific application requirements.

ITT Conoflow’s HP635 Series unit is a high-flow, high-purity regulator that is designed as a purge gas regulator and may be used in high purity gas systems involving corrosive and toxic media. All wetted components are of a 316 Stainless Steel construction having a maximum 35Ra surface finish. An optional brass model (NPT port only) is available for inert gas service.This unit has a large main valve providing a flow capacity of Cv=1.8 at the valve. Connections are 1/2” NPT or 1/2” Tube Stubs with either style having a maximum supply pressure rating of 500 psig. Outlet pressure ranges of 0-25, 0-50, 0-100, 0-150 and 0-200 psig (0-0.173, 0-0.345, 0-0.69, 0-1.04, and 0-138 MPa) are available. The HP635 Regulator is offered with an inboard and across the seat leakage specification of 2 x 10-8 atm. cc/sec Helium. Also, there is an adjustable stop that may be set to limit pressure control settings for specific application requirements. -

Conoflow’s HP700 Series regulator is a two-stage, high purity unit designed to provide constant outlet pressure regardless of inlet pressure fluctuations. This unit is available in either brass or stainless steel construction. Maximum supply pressure rating for either material is 3500 PSIG (24.2 MPa). To provide optimum performance in specific applications, this unit is offered with relieving, non-relieving, and tied (non-relieving) diaphragm options.Typical applications for the HP700 regulator are gas chromatography, calibration systems, cylinder gases, and precise regulation of corrosive and non-corrosive media. Adjustment within each of five available ranges is made with a standard large handwheel. A wrench style knob with a locking device and a “T” bar handle are available as optional adjustments. This unit is supplied with 1/4” inlet and outlet connections. Inlet and outlet gauge ports (1/4” NPT) are standard. High purity internal connections and VCR, Vacuseal and Ultra Seal welded fittings are optional. Captured bonnets for both stages are standard. This regulator is designed for reliability with an absolute minimum of maintenance.The characteristics are a result of Conoflow’s high standards of manufacturing and years of experience as a leading manufacturer of pneumatic instrumentation.

Conoflow’s HP700 Series regulator is a two-stage, high purity unit designed to provide constant outlet pressure regardless of inlet pressure fluctuations. This unit is available in either brass or stainless steel construction. Maximum supply pressure rating for either material is 3500 PSIG (24.2 MPa). To provide optimum performance in specific applications, this unit is offered with relieving, non-relieving, and tied (non-relieving) diaphragm options.Typical applications for the HP700 regulator are gas chromatography, calibration systems, cylinder gases, and precise regulation of corrosive and non-corrosive media. Adjustment within each of five available ranges is made with a standard large handwheel. A wrench style knob with a locking device and a “T” bar handle are available as optional adjustments. This unit is supplied with 1/4” inlet and outlet connections. Inlet and outlet gauge ports (1/4” NPT) are standard. High purity internal connections and VCR, Vacuseal and Ultra Seal welded fittings are optional. Captured bonnets for both stages are standard. This regulator is designed for reliability with an absolute minimum of maintenance.The characteristics are a result of Conoflow’s high standards of manufacturing and years of experience as a leading manufacturer of pneumatic instrumentation. -

When Hydrogen purity drops, windage losses and operating costs increase, resulting in lost revenue and profitability. Gas purity is also a critical life safety issue, making monitoring for potentially explosive levels essential. E/One's Hydrogen Control Cabinet (HCC) was designed specifically for monitoring and controlling hydrogen purity in GE generators that utilize scavenging seal oil systems. The HCC contains two independent analyzers that monitor hydrogen purity from both the turbine-end seal drain enlargement and the collector-end seal drain enlargement. Designed to be used in a hazardous location, the HCC has the ability to automatically increase the amount of hydrogen gas bled from the generator. It's also an easy replacement for your old hydrogen control cabinet. Featuring digital displays, warnings and alarms, the HCC works with all GE and non-GE control systems.

When Hydrogen purity drops, windage losses and operating costs increase, resulting in lost revenue and profitability. Gas purity is also a critical life safety issue, making monitoring for potentially explosive levels essential. E/One's Hydrogen Control Cabinet (HCC) was designed specifically for monitoring and controlling hydrogen purity in GE generators that utilize scavenging seal oil systems. The HCC contains two independent analyzers that monitor hydrogen purity from both the turbine-end seal drain enlargement and the collector-end seal drain enlargement. Designed to be used in a hazardous location, the HCC has the ability to automatically increase the amount of hydrogen gas bled from the generator. It's also an easy replacement for your old hydrogen control cabinet. Featuring digital displays, warnings and alarms, the HCC works with all GE and non-GE control systems. -

From simple signal conditioning, to sensor-level I/O, to complex distributed intelligence, the versatile I/O EQUATION STATION ® is your solution. Even though it’s the same size as a typical process instrument, this multifunction I/O module configures to handle both routine, and one-of-a-kind, applications:

From simple signal conditioning, to sensor-level I/O, to complex distributed intelligence, the versatile I/O EQUATION STATION ® is your solution. Even though it’s the same size as a typical process instrument, this multifunction I/O module configures to handle both routine, and one-of-a-kind, applications: