The BULLET WirelessHART Adapter enables new and existing wired smart HART fi eld devices, non-smart analog fi eld devices and remote HART I/O from any supplier to communicate with host applications using WirelessHART technology.

The BULLET WirelessHART Adapter enables new and existing wired smart HART fi eld devices, non-smart analog fi eld devices and remote HART I/O from any supplier to communicate with host applications using WirelessHART technology.

-

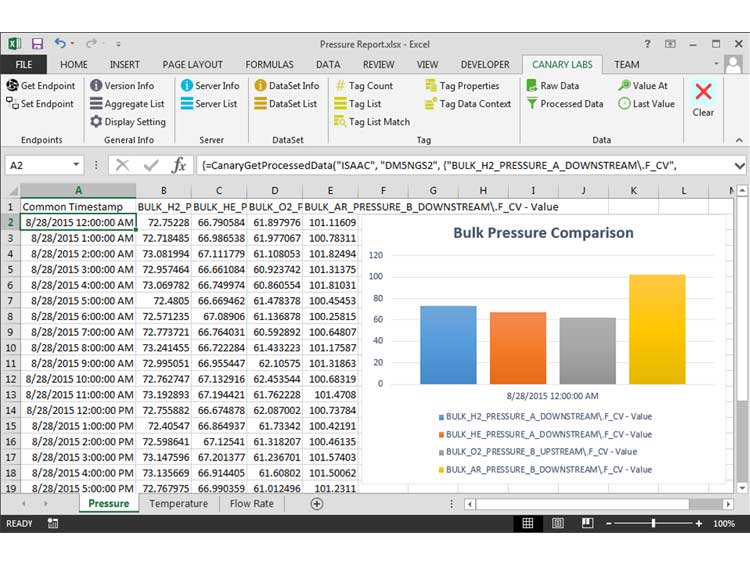

Canary Lab's Reports

Pull your data into Excel using our Excel Add-In. You can retrieve raw or processed data that can be used to generate reports, analyze data, and make business decisions.Features:

- Ribbon ... Use buttons in the ribbon to open dialogs that will build or modify your calls to our Historian

- Connection ... Connect to remote Historians, or connect using credentials if security is turned on

- Raw Data ... Retrieve raw data from the historian. Choose display options for the data

- Processed Data ... Retrieve processed data from the historian. There are a number of aggregates that can be used

-

Canary Lab's Alarms

Use TopView® to monitor your process and automation data. Generate audible alarms, send e-mail notification, SMS/text notification, voice notification and SNMP traps.Features:

- Monitor ... Access to values, alarms, and alarm history

- Notify ... Robust notification engine supporting a wide variety of devices

- Analyze ... Built-in alarm reports can be scheduled and emailed

- Scalable ... Monitor 100 tags or 100,000 tags

-

Canary Lab's Axiom

Maximize your data historian by analyzing process data in the most advanced trending software available. Innovative, easy to use, and feature rich, Axiom will transform your ability to trend process data and gather knowledge from your data historian.Features:

- Ad Hoc Trends ... Add or remove trends quickly using our browse dialog to pick which trends you want to view

- Calculated Trends ... Use standard calculator operations to add a calculated trend based on one or more trends

- Link Scales/Bands ... Link scales of two or more trends so their data is displayed between the same ranges. Link bands to overlap trends

- Limit Lines ... Set limit lines for a trend. Use limits to draw a horizontal line across the screen, to fill in space between a limit and the trend, or to change the color of the trend

- Value Cursor ... Use your cursor to hover over the chart and view the values as you move your mouse

- Zoom ... Quickly zoom in on a range of data to examine it more closely

-

Canary Lab's Data Historian

Our process data historian writes and retrieves historical data with industry leading speed. It can store millions of tags accurately and reliably without any data management.Features:

- Scalable ... capable of storing data for millions of tags

- Fast Read/Write ... Writes up to 4,000,000 points per second

- Data Handling ... Handles sub second data down to 100 nanoseconds

- Data Integrity ... Lossless compression algorithms are used

- Data Accessibility ... OPC, HDA, and ODBC compatible. We also have an API

- Custom Views ... Custom hierarchical models of the data can be created

- Easy Administration ... Easy data management without a database administrator

- Limitless Storage ... No need to purge or optimize the database

- Tag Security ... Tag security so you have complete control of data access

-

Substantially reduce the cost of transmitting process signals with Moore Industries’ unique problem solver, the CCS® Cable Concentrator System®. The industryfirst CCS provides money-saving solutions for both monitoring and control applications. Data Acquisition—The CCS collects any combination of up to 496 analog and/or digital signals from dispersed devices (transmitters, transducers, contact closures, etc.). It digitizes and concentrates the signals on to an RS-485 communication link, and sends the data miles between locations. Control—With the CCS, you can transmit control signals long distances on a single data link to valves, pumps, motors, and other devices that require precise on/off or proportional control.

Substantially reduce the cost of transmitting process signals with Moore Industries’ unique problem solver, the CCS® Cable Concentrator System®. The industryfirst CCS provides money-saving solutions for both monitoring and control applications. Data Acquisition—The CCS collects any combination of up to 496 analog and/or digital signals from dispersed devices (transmitters, transducers, contact closures, etc.). It digitizes and concentrates the signals on to an RS-485 communication link, and sends the data miles between locations. Control—With the CCS, you can transmit control signals long distances on a single data link to valves, pumps, motors, and other devices that require precise on/off or proportional control. -

Circulation Heaters Type Ex. Designed for forced flow or natural flow applications. Standard designs ranging from 0.6 to 672kW… higher kWratings are also available.Optional features include built in high limits and thermostats, stainless steel wetted parts. moisture resistant or explosion-proof housings. CRN registered vessels for Canada. Authorized to bear the U and N stamps, depending on ASME code classification (Section VIII or III)

Circulation Heaters Type Ex. Designed for forced flow or natural flow applications. Standard designs ranging from 0.6 to 672kW… higher kWratings are also available.Optional features include built in high limits and thermostats, stainless steel wetted parts. moisture resistant or explosion-proof housings. CRN registered vessels for Canada. Authorized to bear the U and N stamps, depending on ASME code classification (Section VIII or III) -

eltherms’ Clean Laser Seal technology takes Mineral Insulated (MI) Trace Heater assemblies to the next level.Manufactured and assembled entirely from high quality stainless steel or Alloy 825, eltherm‘s revolutionary Clean Laser Seal Technology (CLS) guarantees performance and reliability in all industrial operations.CLS offers today‘s best possible protection from stress corrosion cracking in applications in which aggressive chemicals may be present.Stainless steel and Alloy 825 is the material of choice for temperature process control and ideally suited for freeze protection or viscosity control applications subject to periodic high temperature exposure.Our proprietary clean laser sealing process provides a 100% stable, homogeneous system, resulting in a reliable and maintenance-free assembly.

eltherms’ Clean Laser Seal technology takes Mineral Insulated (MI) Trace Heater assemblies to the next level.Manufactured and assembled entirely from high quality stainless steel or Alloy 825, eltherm‘s revolutionary Clean Laser Seal Technology (CLS) guarantees performance and reliability in all industrial operations.CLS offers today‘s best possible protection from stress corrosion cracking in applications in which aggressive chemicals may be present.Stainless steel and Alloy 825 is the material of choice for temperature process control and ideally suited for freeze protection or viscosity control applications subject to periodic high temperature exposure.Our proprietary clean laser sealing process provides a 100% stable, homogeneous system, resulting in a reliable and maintenance-free assembly.Features:

- Factory terminated laser sealed technology

- All components in high quality stainless steel or Alloy 825

- High temperature resistance

- High chemical resistance

- High power output

- Flexible single or twin conductor configurations

- Moisture proof, may be immersed in fluid

Applications in Detail:

- Freeze/viscosity protection in industrial processes

- Process temperature maintain

- Vendor skids and process modules (cookie cutter custom units)

- Heat tracing of instrumentation and sample stations

- Vessel and trim tracing

- High temperature exposure

- Aseptic manufacturing conditions

- High watt density requirements

- Vacuum Processes

- Heat Treating Processes

- Heat tracing on instrumentation

-

The CPMS Cathodic Protection Monitoring System monitors above and below ground impressed current cathodic protection systems to ensure that proper corrosion protection is in place and operating at the right levels. Part of Moore Industries’ NET Concentrator System® family of intelligent distributed I/O, the CPMS monitors the critical current and voltage levels of one or two transformer rectifi ers used in cathodic protection systems.

The CPMS Cathodic Protection Monitoring System monitors above and below ground impressed current cathodic protection systems to ensure that proper corrosion protection is in place and operating at the right levels. Part of Moore Industries’ NET Concentrator System® family of intelligent distributed I/O, the CPMS monitors the critical current and voltage levels of one or two transformer rectifi ers used in cathodic protection systems. -

Compact flow meter which integrates in a the same body the sensor and the converter

Sensor body in galvanized zinc steel PTFE coated with SS electrodes.

Available sizes DN10 – DN 15 and DN20

Threaded process connections

Configuration via PC

Pulse and Analogue outputs

Capability to measure the process temperature

Suitable for flow control where flow might need to be controlled according to the temperature such as cooling systems on tooling machines, washing systems etc.

Please refer to the enclosed documentation for further information.

Compact flow meter which integrates in a the same body the sensor and the converter

Sensor body in galvanized zinc steel PTFE coated with SS electrodes.

Available sizes DN10 – DN 15 and DN20

Threaded process connections

Configuration via PC

Pulse and Analogue outputs

Capability to measure the process temperature

Suitable for flow control where flow might need to be controlled according to the temperature such as cooling systems on tooling machines, washing systems etc.

Please refer to the enclosed documentation for further information.