SSX/SST Safety Series Isolator & Splitter

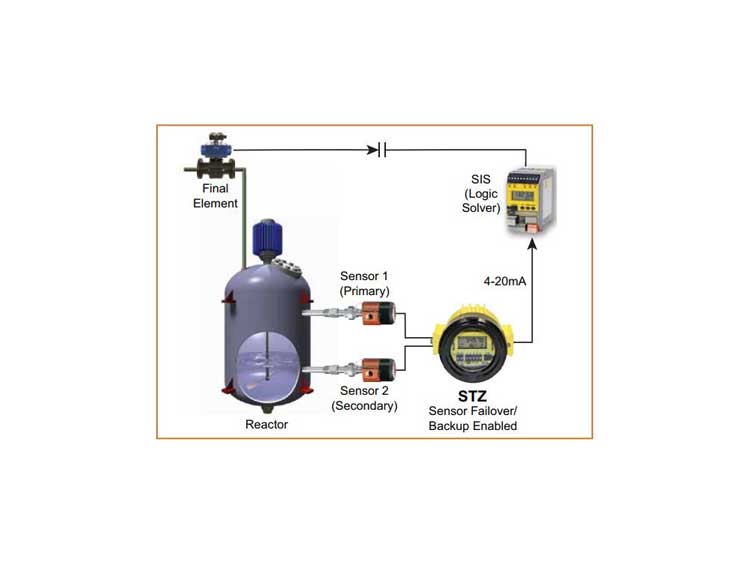

FS Functional Safety Series, the exida® approved, SIL 3 capable 2-wire (loop powered) SSX and 4-wire (line/mains powered) SST Safety Isolators and Splitters provide isolation and signal conversion for your SIS (Safety Instrumented System) needs. These units protect and enhance loops and also pass valuable HART® data from the field transmitter to host systems and vice-versa.

Isolate your SIS from your Basic Process Control System or monitoring system so disconnections or failures to these secondary systems don’t affect your safety system. FMEDA (Failure Mode Effects and Diagnostic Analysis) reports are available with the required safety data to ensure that risk reduction requirements are met.

Protect your safety system from surges, spikes and transients in the field. With 1500Vrms isolating capability, the SSX/SST protects your safety I/O cards and system from the rigors of plant environments.

With built-in HART pass-through technology you can rest assured that when your loops use HART transmitters that critical and valuable HART diagnostic, process, and calibration information can be read on either side of the SSX/SST. Most all other isolators block and “strip off” the HART signal.

Features:

- exida certified IEC 61508:2010. exida has certified the SSX/SST for use in an SIS up to SIL 3 in monitor mode, where only the input circuit is part of the safety function. For single use mode, the SSX/SST is approved for use in an SIS up to SIL 2.

- Comprehensive FMEDA certified safety data. Upon request, exida-certified FMEDA data is provided to be used by a functional safety practitioner to determine the SST’s and SSX’s applicability in specific safety-related applications.

- Valuable HART data not lost. Both the SSX and SST pass critical HART data to asset management systems, programming devices or host systems.

- Split signals between two locations. The 4-Wire SST takes in one signal and gives you two fully isolated outputs that can be taken to two separate receiving devices. This facilitates maintenance on either output loop without losing the signal on the other output loop.

- RFI/EMI Protection. Standard 20V/m protection offered to protect against harmful effects of radio frequency and electromagnetic interference.

- Transmitter excitation. The 4-wire SST is capable of providing loop power to a 2-wire transmitter that is connected to its input.