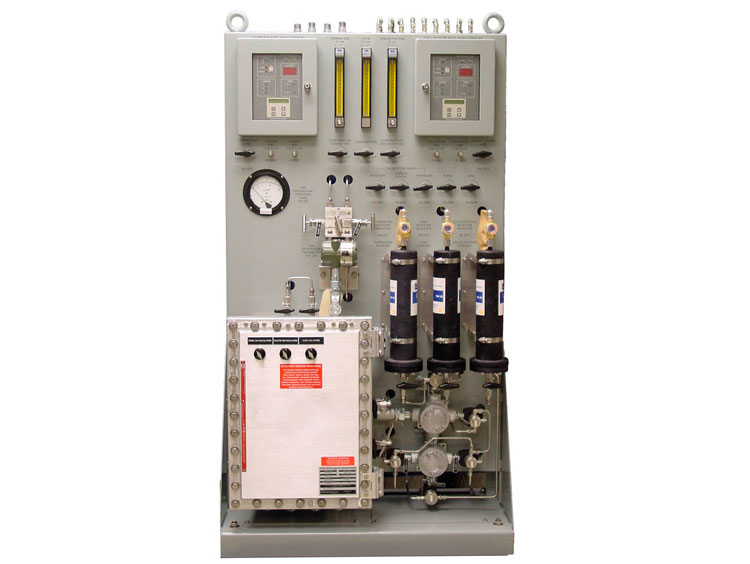

Environment One's Dual Hydrogen Control Panel (DHCP) was designed specifically for monitoring GE's scavenging seal oil generators. The DHCP contains two independent analyzers that monitor the turbine-end seal drain enlargement, collector-end seal oil drain enlargement with both valving for manual or DCS operation for checking casing purity of the generator.

Environment One's Dual Hydrogen Control Panel (DHCP) was designed specifically for monitoring GE's scavenging seal oil generators. The DHCP contains two independent analyzers that monitor the turbine-end seal drain enlargement, collector-end seal oil drain enlargement with both valving for manual or DCS operation for checking casing purity of the generator. -

Environment One's Dual Hydrogen Control Panel (DHCP) was designed specifically for monitoring GE's scavenging seal oil generators. The DHCP contains two independent analyzers that monitor the turbine-end seal drain enlargement, collector-end seal oil drain enlargement with both valving for manual or DCS operation for checking casing purity of the generator.

Environment One's Dual Hydrogen Control Panel (DHCP) was designed specifically for monitoring GE's scavenging seal oil generators. The DHCP contains two independent analyzers that monitor the turbine-end seal drain enlargement, collector-end seal oil drain enlargement with both valving for manual or DCS operation for checking casing purity of the generator. -

CX Domestic Immersion Heaters were developed as high quality replacements for the most commonly used heater types. The CXC is available in a range of styles, including 2.5" (64 mm) square flange with tinned copper sheath, 1" (25 mm) tapered brass plug with copper sheath, 1" (25 mm) non-tapered brass plug with copper sheath and round flange with zinc plated copper sheath. The CXI is available with a 2.5" (64 mm) square flange with Incoloy® sheath. Elements are epoxy-coated to protect the heater from moisture and other contaminants that can lead to premature element failure.

CX Domestic Immersion Heaters were developed as high quality replacements for the most commonly used heater types. The CXC is available in a range of styles, including 2.5" (64 mm) square flange with tinned copper sheath, 1" (25 mm) tapered brass plug with copper sheath, 1" (25 mm) non-tapered brass plug with copper sheath and round flange with zinc plated copper sheath. The CXI is available with a 2.5" (64 mm) square flange with Incoloy® sheath. Elements are epoxy-coated to protect the heater from moisture and other contaminants that can lead to premature element failure. -

The D074 is a basic, panel mount level / pump controller that works with a pre-set value and two switch points to control a pump or valve. The low and high level switch points are entered as a percentage of the pre-set value to switch the device on / off. For pump control applications, the function can be inverted to empty a well. A stable level within a hysteresis around the pre-set value is the result.

The D074 is a basic, panel mount level / pump controller that works with a pre-set value and two switch points to control a pump or valve. The low and high level switch points are entered as a percentage of the pre-set value to switch the device on / off. For pump control applications, the function can be inverted to empty a well. A stable level within a hysteresis around the pre-set value is the result.

-

The D074 is a basic, panel mount level / pump controller that works with a pre-set value and two switch points to control a pump or valve. The low and high level switch points are entered as a percentage of the pre-set value to switch the device on / off. For pump control applications, the function can be inverted to empty a well. A stable level within a hysteresis around the pre-set value is the result.

The D074 is a basic, panel mount level / pump controller that works with a pre-set value and two switch points to control a pump or valve. The low and high level switch points are entered as a percentage of the pre-set value to switch the device on / off. For pump control applications, the function can be inverted to empty a well. A stable level within a hysteresis around the pre-set value is the result.

-

The D090 is a local, panel mount indicator to display the actual process value, range and loop current. The measuring unit to be displayed is simply selected through an alfa-numerical configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user friendly solution! The configuration of Span, offset and number of decimals is done through software functions, without any sensitive dip-switches or trimmers.

The D090 is a local, panel mount indicator to display the actual process value, range and loop current. The measuring unit to be displayed is simply selected through an alfa-numerical configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user friendly solution! The configuration of Span, offset and number of decimals is done through software functions, without any sensitive dip-switches or trimmers. -

The D013 is a versatile, panel mount flow rate indicator and totalizer with continuous flow rate monitoring feature. It offers the facility to set one low flow rate and one high flow rate alarm value. If desired, a delay function can be set up to allow for an incorrect flow rate for a certain period of time.

The D013 is a versatile, panel mount flow rate indicator and totalizer with continuous flow rate monitoring feature. It offers the facility to set one low flow rate and one high flow rate alarm value. If desired, a delay function can be set up to allow for an incorrect flow rate for a certain period of time. -

The D016 is a local panel mount indicator / transmitter with linearization to display the actual flow rate, total and accumulated total. The total can be reset to zero by pressing the CLEAR button twice. The eleven digit accumulated total however cannot be reset to zero. In addition to the average K-Factor or Span, eight linearization points can be entered with their frequencies or values. The unit will interpolate between these points greatly enhancing accuracy in any flow range. Even for very low frequency applications is catered for. This linearization affects all displayed information as well as the pulse output.

The D016 is a local panel mount indicator / transmitter with linearization to display the actual flow rate, total and accumulated total. The total can be reset to zero by pressing the CLEAR button twice. The eleven digit accumulated total however cannot be reset to zero. In addition to the average K-Factor or Span, eight linearization points can be entered with their frequencies or values. The unit will interpolate between these points greatly enhancing accuracy in any flow range. Even for very low frequency applications is catered for. This linearization affects all displayed information as well as the pulse output. -

The D040 is a straight forward, panel mount temperature indicator. The measuring unit to be displayed is simply selected through an alfa-numerical configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user friendly solution! The configuration of the Span, off-set and number of decimals is done through software functions, without any sensitive dip-switches or trimmers.

Advantages

Unique, robust IP66, IP67 (Type4X) panel mount front enclosure made of die cast aluminum, allowing even big jets of water and total immersion.

Programming can be done by your own crew with the exact same, plain and sensible menu-driven structure like the F-Series, saving cost and irritation. Know one, know them all!

The D040 is a straight forward, panel mount temperature indicator. The measuring unit to be displayed is simply selected through an alfa-numerical configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user friendly solution! The configuration of the Span, off-set and number of decimals is done through software functions, without any sensitive dip-switches or trimmers.

Advantages

Unique, robust IP66, IP67 (Type4X) panel mount front enclosure made of die cast aluminum, allowing even big jets of water and total immersion.

Programming can be done by your own crew with the exact same, plain and sensible menu-driven structure like the F-Series, saving cost and irritation. Know one, know them all! -

The D053 is a versatile, panel mount pressure indicator with continuous pressure monitoring feature. It offers the facility to set one low pressure and one high pressure alarm value. If desired, an ignore function can be set up to allow for an incorrect pressure for a certain period of time.

Advantages

Unique, robust IP66, IP67 (Type4X) panel mount front enclosure made of die cast aluminum, allowing even big jets of water and total immersion.

Programming can be done by your own crew with the exact same, plain and sensible menu-driven structure like the F-Series, saving cost and irritation. Know one, know them all!

The D053 is a versatile, panel mount pressure indicator with continuous pressure monitoring feature. It offers the facility to set one low pressure and one high pressure alarm value. If desired, an ignore function can be set up to allow for an incorrect pressure for a certain period of time.

Advantages

Unique, robust IP66, IP67 (Type4X) panel mount front enclosure made of die cast aluminum, allowing even big jets of water and total immersion.

Programming can be done by your own crew with the exact same, plain and sensible menu-driven structure like the F-Series, saving cost and irritation. Know one, know them all! -

D74 2-PIECE INDUSTRIAL SEAL

DESCRIPTION & FEATURES

- Two piece construction and designed to withstand even the most severe process applications

- “Continuous use” seals – backing plate will prevent diaphragm from rupturing if pressure sensing instrument fails. Pressure will be held until instrument is replaced

- Diaphragm is separable for servicing and is available with a 1/4” NPT flushing connection for removing any material which may clog the process connection

- Standard diaphragm is constructed of AISI 316 stainless steel and welded to the upper chamber of the seal

- ASME B40.100 compliant

- 5 year warranty

APPLICATIONS

Where the media is low in pressure and the process fluid is corrosive or viscous and would clog instrument internals/solidify within the pressure gauge, switch or transmitter