the control signal (4-20mA) is hard wired to pass through the 531 without degradation. In LOCAL mode, the 531 generates the CV (control) signal in AUTO or MANUAL mode. Host CV tracking enables a bumpless transfer to LOCAL mode in either LOCAL AUTO or LOCAL MANUAL mode. A special CV line sense function triggers HOST to LOCAL transfer automatically if host CV signal fails. LOCAL/HOST transfer may also be initiated by a dedicated front panel key or a contact input. The 531's setpoint may be set locally or remotely from the host, ensuring bumpless changeover to LOCAL AUTO mode. The 531 may also be operated as a manual loading station in the LOCAL MANUAL mode.

the control signal (4-20mA) is hard wired to pass through the 531 without degradation. In LOCAL mode, the 531 generates the CV (control) signal in AUTO or MANUAL mode. Host CV tracking enables a bumpless transfer to LOCAL mode in either LOCAL AUTO or LOCAL MANUAL mode. A special CV line sense function triggers HOST to LOCAL transfer automatically if host CV signal fails. LOCAL/HOST transfer may also be initiated by a dedicated front panel key or a contact input. The 531's setpoint may be set locally or remotely from the host, ensuring bumpless changeover to LOCAL AUTO mode. The 531 may also be operated as a manual loading station in the LOCAL MANUAL mode. Moore Industries is a world leader in the design and manufacture of interface instruments for industrial process control, system integration, and factory automation. Providing products and services to fortune 500 companies worldwide, the products of Moore Industries are used in industries such as: chemical and petrochemical; power generation and transmission; petroleum extraction, refining and transport; pulp and paper; food and beverage; mining and metal refining; pharmaceuticals and biotechnology; industrial machinery and equipment; water and wastewater; and environmental and pollution monitoring.

-

The 531 provides automatic PID control backup for critical loops controlled by PLC, DCS or PC systems. Unlike a single loop controller configured to sense and retransmit a control signal, which adds liability and complexity; the 531 has a simple operator interface, special parameters for control states upon host transfer or failure, and a special pass-through circuit that provides redundancy in the control loop. In HOST mode,

The 531 provides automatic PID control backup for critical loops controlled by PLC, DCS or PC systems. Unlike a single loop controller configured to sense and retransmit a control signal, which adds liability and complexity; the 531 has a simple operator interface, special parameters for control states upon host transfer or failure, and a special pass-through circuit that provides redundancy in the control loop. In HOST mode, the control signal (4-20mA) is hard wired to pass through the 531 without degradation. In LOCAL mode, the 531 generates the CV (control) signal in AUTO or MANUAL mode. Host CV tracking enables a bumpless transfer to LOCAL mode in either LOCAL AUTO or LOCAL MANUAL mode. A special CV line sense function triggers HOST to LOCAL transfer automatically if host CV signal fails. LOCAL/HOST transfer may also be initiated by a dedicated front panel key or a contact input. The 531's setpoint may be set locally or remotely from the host, ensuring bumpless changeover to LOCAL AUTO mode. The 531 may also be operated as a manual loading station in the LOCAL MANUAL mode.

the control signal (4-20mA) is hard wired to pass through the 531 without degradation. In LOCAL mode, the 531 generates the CV (control) signal in AUTO or MANUAL mode. Host CV tracking enables a bumpless transfer to LOCAL mode in either LOCAL AUTO or LOCAL MANUAL mode. A special CV line sense function triggers HOST to LOCAL transfer automatically if host CV signal fails. LOCAL/HOST transfer may also be initiated by a dedicated front panel key or a contact input. The 531's setpoint may be set locally or remotely from the host, ensuring bumpless changeover to LOCAL AUTO mode. The 531 may also be operated as a manual loading station in the LOCAL MANUAL mode. -

The 532 Auto/Manual Station ensures the integrity of your processes with maximum reliability. Isolated inputs and outputs guard against electrical interference, the front face meets NEMA 4X standards for watertight operation, and solid metal housing and sturdy rubber keys enhance durability. The 532 has been engineered to be the industry’s most user friendly and comprehensive Auto/Manual Station. It has three digital display areas, with two offering up to 9 characters of true alphanumerics. The bright, crisp vacuum fluorescent display offers better readability than any other display technology. Additional operator friendly features include: custom programmable alarm messages, keys that illuminate when in use and an easy-to-use menu system.

The 532 Auto/Manual Station ensures the integrity of your processes with maximum reliability. Isolated inputs and outputs guard against electrical interference, the front face meets NEMA 4X standards for watertight operation, and solid metal housing and sturdy rubber keys enhance durability. The 532 has been engineered to be the industry’s most user friendly and comprehensive Auto/Manual Station. It has three digital display areas, with two offering up to 9 characters of true alphanumerics. The bright, crisp vacuum fluorescent display offers better readability than any other display technology. Additional operator friendly features include: custom programmable alarm messages, keys that illuminate when in use and an easy-to-use menu system. -

The 535 is a 1/4 DIN single loop process controller (SLC) designed to control any analog process variable (temperature, pressure, flow, level, etc.) in batch and continuous processes. The 535’s outstanding feature mix enables it to bring processes under control faster, more accurately and easily than competitive SLC’s, PLC, and PC based control systems.

The 535 is a 1/4 DIN single loop process controller (SLC) designed to control any analog process variable (temperature, pressure, flow, level, etc.) in batch and continuous processes. The 535’s outstanding feature mix enables it to bring processes under control faster, more accurately and easily than competitive SLC’s, PLC, and PC based control systems. -

Substantially reduce the cost of transmitting process signals with Moore Industries’ unique problem solver, the CCS® Cable Concentrator System®. The industryfirst CCS provides money-saving solutions for both monitoring and control applications. Data Acquisition—The CCS collects any combination of up to 496 analog and/or digital signals from dispersed devices (transmitters, transducers, contact closures, etc.). It digitizes and concentrates the signals on to an RS-485 communication link, and sends the data miles between locations. Control—With the CCS, you can transmit control signals long distances on a single data link to valves, pumps, motors, and other devices that require precise on/off or proportional control.

Substantially reduce the cost of transmitting process signals with Moore Industries’ unique problem solver, the CCS® Cable Concentrator System®. The industryfirst CCS provides money-saving solutions for both monitoring and control applications. Data Acquisition—The CCS collects any combination of up to 496 analog and/or digital signals from dispersed devices (transmitters, transducers, contact closures, etc.). It digitizes and concentrates the signals on to an RS-485 communication link, and sends the data miles between locations. Control—With the CCS, you can transmit control signals long distances on a single data link to valves, pumps, motors, and other devices that require precise on/off or proportional control. -

The CPMS Cathodic Protection Monitoring System monitors above and below ground impressed current cathodic protection systems to ensure that proper corrosion protection is in place and operating at the right levels. Part of Moore Industries’ NET Concentrator System® family of intelligent distributed I/O, the CPMS monitors the critical current and voltage levels of one or two transformer rectifi ers used in cathodic protection systems.

The CPMS Cathodic Protection Monitoring System monitors above and below ground impressed current cathodic protection systems to ensure that proper corrosion protection is in place and operating at the right levels. Part of Moore Industries’ NET Concentrator System® family of intelligent distributed I/O, the CPMS monitors the critical current and voltage levels of one or two transformer rectifi ers used in cathodic protection systems. -

The ECA DIN-style Alarm features a solid metal housing that stands up to the continual rigors of process control and factory automation applications. Rugged and reliable, the 4-wire (line-powered) ECA is the low-cost solution when alarm trip outputs are needed to indicate high or low process conditions. Available models accept current and voltage input from field transmitters, transducers, and other process instruments. When the input falls outside of a pre-set limit (user configurable), the ECA provides contact closure outputs ideal for indicating a high and/or low condition via a bell, buzzer, light or other annunciating device.

The ECA DIN-style Alarm features a solid metal housing that stands up to the continual rigors of process control and factory automation applications. Rugged and reliable, the 4-wire (line-powered) ECA is the low-cost solution when alarm trip outputs are needed to indicate high or low process conditions. Available models accept current and voltage input from field transmitters, transducers, and other process instruments. When the input falls outside of a pre-set limit (user configurable), the ECA provides contact closure outputs ideal for indicating a high and/or low condition via a bell, buzzer, light or other annunciating device. -

ECT DIN-style signal isolators, converters, repeaters, boosters and splitters feature solid metal housings that stand up to the continuous, daily rigors of process control and factory automation applications. Rugged and reliable, the ECT is available in 2-wire (loop) and 4-wire (line/mains) powered models. The complete family delivers economical solutions for an expansive range of signal interface applications.

Download Data Sheet

ECT DIN-style signal isolators, converters, repeaters, boosters and splitters feature solid metal housings that stand up to the continuous, daily rigors of process control and factory automation applications. Rugged and reliable, the ECT is available in 2-wire (loop) and 4-wire (line/mains) powered models. The complete family delivers economical solutions for an expansive range of signal interface applications.

Download Data Sheet -

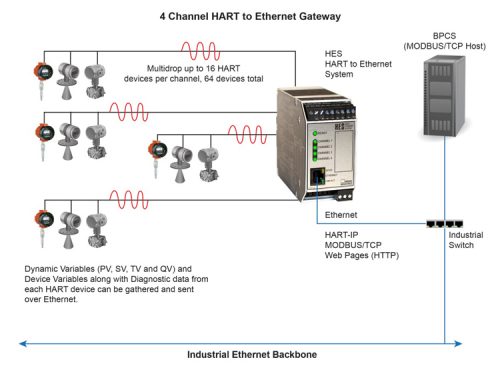

HES HART to Ethernet Gateway System converts signals from wired HART devices to Ethernet MODBUS/TCP and HART-IP

Timely knowledge about your process enables better decisions and faster preventive action. Now you can get the process detail that you need from your Smart HART devices to MODBUS/TCP and HART-IP based monitoring and control systems at the speed of Ethernet with the HES HART to Ethernet Gateway System. Connect up to 64 Smart HART devices to the HES and collect the Dynamic Variables and the Device Variables, along with diagnostic bits and bytes, from each device that helps deliver critical information needed to help you address process and device problems before they turn into unplanned downtime. Moore Industries’ rugged HES supports HART 5, 6 and 7 devices with sufficient memory to handle thousands of process variables, and diagnostic data points from up to 64 connected smart HART devices. The HES allows you to further leverage your industrial Ethernet investment by making all of this valuable HART data viewable with any web browser or MODBUS/TCP compliant host. Support for these open industrial protocols enables you to easily interface with any process control or asset management system while taking advantage of any Industrial Internet of Things (IIoT) initiatives that facilitate the propagation of process data to higher level corporate or analytical systems. -

The HIM HART Loop Interface and Monitor unlocks the full potential of new and in-place smart HART multivariable transmitters and valves. Converts HART to 4-20mA Signals The HIM allows up to three additional analog process variable measurements from a smart device with no additional process penetrations or wiring.

Download Data Sheet

The HIM HART Loop Interface and Monitor unlocks the full potential of new and in-place smart HART multivariable transmitters and valves. Converts HART to 4-20mA Signals The HIM allows up to three additional analog process variable measurements from a smart device with no additional process penetrations or wiring.

Download Data Sheet -

HIT/HIX HART® Isolators provide highly economical solutions to common and costly problems that plague many of today’s “smart” process loops. Protect and enhance your HART investment with the 2-wire (loop powered) HIX or the 4-wire (line-mains powered) HIT.

Download Data Sheet

HIT/HIX HART® Isolators provide highly economical solutions to common and costly problems that plague many of today’s “smart” process loops. Protect and enhance your HART investment with the 2-wire (loop powered) HIX or the 4-wire (line-mains powered) HIT.

Download Data Sheet -

From simple signal conditioning, to sensor-level I/O, to complex distributed intelligence, the versatile I/O EQUATION STATION ® is your solution. Even though it’s the same size as a typical process instrument, this multifunction I/O module configures to handle both routine, and one-of-a-kind, applications:

From simple signal conditioning, to sensor-level I/O, to complex distributed intelligence, the versatile I/O EQUATION STATION ® is your solution. Even though it’s the same size as a typical process instrument, this multifunction I/O module configures to handle both routine, and one-of-a-kind, applications: -

The rugged IPF Field-Mounted Current-to-Pressure Transmitter is designed specifically for installation in harsh environments. The two-wire IPF accepts a 4-20mA or 10-50mA input. It converts the input to a 3-15psig, 0.2-1bar, 15-3psig or 1-0.2bar pneumatic output signal, or to a wide variety of other commonly used pneumatic outputs (see Specifications for details). This versatility allows the IPF to interface with just about any kind of process control instrumentation including chart recorders, data loggers, panel meters, multiplexers, controllers and computers. The IPF can either be surface-mounted or mounted directly on a two-inch (vertical or horizontal) pipe. Two different types of housings are offered. The standard WP housing provides 1/2-inch NPT female wire entry threads while the metric WPM housing provides M20X1.5 female wire entry threads. The IPF transmitter is also available with an optional coalescing filter/regulator that combines both an air filter and a miniature supply line regulator. For more information on

The rugged IPF Field-Mounted Current-to-Pressure Transmitter is designed specifically for installation in harsh environments. The two-wire IPF accepts a 4-20mA or 10-50mA input. It converts the input to a 3-15psig, 0.2-1bar, 15-3psig or 1-0.2bar pneumatic output signal, or to a wide variety of other commonly used pneumatic outputs (see Specifications for details). This versatility allows the IPF to interface with just about any kind of process control instrumentation including chart recorders, data loggers, panel meters, multiplexers, controllers and computers. The IPF can either be surface-mounted or mounted directly on a two-inch (vertical or horizontal) pipe. Two different types of housings are offered. The standard WP housing provides 1/2-inch NPT female wire entry threads while the metric WPM housing provides M20X1.5 female wire entry threads. The IPF transmitter is also available with an optional coalescing filter/regulator that combines both an air filter and a miniature supply line regulator. For more information on -

These 2-wire (loop-powered) I/P transmitters accept a current signal (such as 4-20mA) from a DCS, PLC or PC-based control system. They convert the current signal to a pneumatic signal (3-15psig, 0.2-1bar, 20-100kPa, etc.) to provide precise, proportional control of valves, actuators and other pneumaticallycontrolled devices. The economical IPH2 (Type 4X) is watertight, dust-protected, and resistant to corrosion and chemicals. In addition to meeting Type 3X/4X requirements, the IPX2 can be installed in explosionproof environments. Both units are available with an optional coalescing fi lter/regulator that combines an air fi lter and miniature supply line regulator with a pressure gauge that reads in both psig and bars.

These 2-wire (loop-powered) I/P transmitters accept a current signal (such as 4-20mA) from a DCS, PLC or PC-based control system. They convert the current signal to a pneumatic signal (3-15psig, 0.2-1bar, 20-100kPa, etc.) to provide precise, proportional control of valves, actuators and other pneumaticallycontrolled devices. The economical IPH2 (Type 4X) is watertight, dust-protected, and resistant to corrosion and chemicals. In addition to meeting Type 3X/4X requirements, the IPX2 can be installed in explosionproof environments. Both units are available with an optional coalescing fi lter/regulator that combines an air fi lter and miniature supply line regulator with a pressure gauge that reads in both psig and bars. -

The high-performance IPT 2 Current-to-Pressure (I/P) Transmitter converts a current signal to a pneumatic signal so that an electronic-based system such as a DCS, PLC, or PC can control a pneumatic actuator, valve, or damper drive. Available models accept a wide range of current inputs (4-20mA, 4-12mA, and 12-20mA) and provide a proportional pneumatic signal (3-15psig, 0.2-1 Bar, 20-100kPA, etc.).

The high-performance IPT 2 Current-to-Pressure (I/P) Transmitter converts a current signal to a pneumatic signal so that an electronic-based system such as a DCS, PLC, or PC can control a pneumatic actuator, valve, or damper drive. Available models accept a wide range of current inputs (4-20mA, 4-12mA, and 12-20mA) and provide a proportional pneumatic signal (3-15psig, 0.2-1 Bar, 20-100kPA, etc.). -

These 2-wire (loop-powered) I/P transmitters accept a current signal (such as 4-20mA) from a DCS, PLC or PC-based control system. They convert the current signal to a pneumatic signal (3-15psig, 0.2-1bar, 20-100kPa, etc.) to provide precise, proportional control of valves, actuators and other pneumaticallycontrolled devices. The economical IPH2 (Type 4X) is watertight, dust-protected, and resistant to corrosion and chemicals. In addition to meeting Type 3X/4X requirements, the IPX2 can be installed in explosionproof environments. Both units are available with an optional coalescing fi lter/regulator that combines an air fi lter and miniature supply line regulator with a pressure gauge that reads in both psig and bars.

Download Data Sheet

These 2-wire (loop-powered) I/P transmitters accept a current signal (such as 4-20mA) from a DCS, PLC or PC-based control system. They convert the current signal to a pneumatic signal (3-15psig, 0.2-1bar, 20-100kPa, etc.) to provide precise, proportional control of valves, actuators and other pneumaticallycontrolled devices. The economical IPH2 (Type 4X) is watertight, dust-protected, and resistant to corrosion and chemicals. In addition to meeting Type 3X/4X requirements, the IPX2 can be installed in explosionproof environments. Both units are available with an optional coalescing fi lter/regulator that combines an air fi lter and miniature supply line regulator with a pressure gauge that reads in both psig and bars.

Download Data Sheet -

The microNCS provides a real-time signal gateway between the field or factory floor and your control strategy. Part of Moore Industries’ NCS NET Concentrator System® family of intelligent distributed I/O, the stand-alone microNCS accepts four or eight fully-isolated analog inputs and four discrete (contact closure) inputs. It “concentrates” this data onto one or multiple communication links, and transmits it long distances back to one or more host DCS, PLC or PC-based control systems.

The microNCS provides a real-time signal gateway between the field or factory floor and your control strategy. Part of Moore Industries’ NCS NET Concentrator System® family of intelligent distributed I/O, the stand-alone microNCS accepts four or eight fully-isolated analog inputs and four discrete (contact closure) inputs. It “concentrates” this data onto one or multiple communication links, and transmits it long distances back to one or more host DCS, PLC or PC-based control systems. -

Featuring a very narrow installation footprint,

miniMOORE™ Signal Isolators, Converters, Boosters

and Splitters combine multiple analog signal channels

in a rugged, easy-to-install signal conditioner.

Reliable and very economical, the miniMOORE

multi-channel family includes the model MIX 2-wire

(loop) and the model MIT 4-wire (line/mains) powered

models. The complete family delivers cost-effective

solutions for an expansive range of signal interface

applications.

Featuring a very narrow installation footprint,

miniMOORE™ Signal Isolators, Converters, Boosters

and Splitters combine multiple analog signal channels

in a rugged, easy-to-install signal conditioner.

Reliable and very economical, the miniMOORE

multi-channel family includes the model MIX 2-wire

(loop) and the model MIT 4-wire (line/mains) powered

models. The complete family delivers cost-effective

solutions for an expansive range of signal interface

applications. -

Moore Industries’ PAC and PAV Ac Current and Voltage Transducers accept an ac current (PAC) or ac voltage (PAV) input. They provide a highly accurate (±0.25% of rated output) dc current output. The PAC and PAV respond to the average value of the input signal and are calibrated to indicate the RMS value.

Moore Industries’ PAC and PAV Ac Current and Voltage Transducers accept an ac current (PAC) or ac voltage (PAV) input. They provide a highly accurate (±0.25% of rated output) dc current output. The PAC and PAV respond to the average value of the input signal and are calibrated to indicate the RMS value. -

Moore Industries’ durable PIH Pressure–to-Current Transmitter provides an economical solution for any process that requires a rugged instrument capable of interfacing a pneumatic device with a data acquisition / control system, controller, recorder or other electronic instrument. This compact yet powerful unit accepts most pneumatic signals (3-15psig, 0.2-1 bar, 3-27 psig etc.) and accurately converts them to a proportional 4-20mA output.

Moore Industries’ durable PIH Pressure–to-Current Transmitter provides an economical solution for any process that requires a rugged instrument capable of interfacing a pneumatic device with a data acquisition / control system, controller, recorder or other electronic instrument. This compact yet powerful unit accepts most pneumatic signals (3-15psig, 0.2-1 bar, 3-27 psig etc.) and accurately converts them to a proportional 4-20mA output. -

Moore Industries’ family of pressure-to-current transmitters provide an economical solution when a pneumatic device must interface with a data acquisiton/control system, controller, recorder, or other electronic instrument. These compact, yet powerful units accept a pneumatic signal (3-15 psig, 0.2-1 bar, 3-27 psig, etc.) and accurately convert it to a proportional 4-20mA (or 10-50mA) output. Control Room and Field Mounting—Our complete line of P/I transmitters includes models perfect for both control room and field mounting. Moore Industries’ P/I transmitters are available with a wide variety of housings, and with special features and options. For detailed information, see Table 1 and the Ordering Specifications table.

Moore Industries’ family of pressure-to-current transmitters provide an economical solution when a pneumatic device must interface with a data acquisiton/control system, controller, recorder, or other electronic instrument. These compact, yet powerful units accept a pneumatic signal (3-15 psig, 0.2-1 bar, 3-27 psig, etc.) and accurately convert it to a proportional 4-20mA (or 10-50mA) output. Control Room and Field Mounting—Our complete line of P/I transmitters includes models perfect for both control room and field mounting. Moore Industries’ P/I transmitters are available with a wide variety of housings, and with special features and options. For detailed information, see Table 1 and the Ordering Specifications table. -

Moore Industries’ universal PSD PC-Programmable Loop Display features a large integral display that shows real-time process status in mA, percent, or any designated 5-character Engineering units (EGU). Superior Accuracy–The loop-powered PSD reads any 4-20mA signal and displays the information with phenomenal accuracy of ±0.012% of input scale. And because it requires less than 2.3 Volts, it won’t burden most loops. Simple and Versatile PC Setup Program– Using the PC software, the PSD can either be custom scaled to display in a percent or scaled directly into engineering units for indicating process measurements such as pressure, temperature, level, or fl ow. Span, zero, input range, display range, and fi ltering frequency can also be easily programmed. Our software will even capture the input range limits of the loop to provide you with the most accurate display available

Moore Industries’ universal PSD PC-Programmable Loop Display features a large integral display that shows real-time process status in mA, percent, or any designated 5-character Engineering units (EGU). Superior Accuracy–The loop-powered PSD reads any 4-20mA signal and displays the information with phenomenal accuracy of ±0.012% of input scale. And because it requires less than 2.3 Volts, it won’t burden most loops. Simple and Versatile PC Setup Program– Using the PC software, the PSD can either be custom scaled to display in a percent or scaled directly into engineering units for indicating process measurements such as pressure, temperature, level, or fl ow. Span, zero, input range, display range, and fi ltering frequency can also be easily programmed. Our software will even capture the input range limits of the loop to provide you with the most accurate display available -

Moore Industries’ AC Power Transducers continuously track the amount of power being consumed by an electric device or a system. Available models accept an AC input from a “load” device such as a motor, pump or heater. They provide a proportional milliamp output for determining equipment power use and operating efficiency. They can also be used to trip automatic power control equipment to initiate energy conservation measures. Moore Industries’ AC power transducers are available in 1, 1-1/2, 2, 2-1/2, and 3 element versions. They may be either self- or externally-powered.

Moore Industries’ AC Power Transducers continuously track the amount of power being consumed by an electric device or a system. Available models accept an AC input from a “load” device such as a motor, pump or heater. They provide a proportional milliamp output for determining equipment power use and operating efficiency. They can also be used to trip automatic power control equipment to initiate energy conservation measures. Moore Industries’ AC power transducers are available in 1, 1-1/2, 2, 2-1/2, and 3 element versions. They may be either self- or externally-powered. -

The R-BOX accommodates transmitters, meters, indicators, analyzers, integrators, and many other rail-mounted instruments. The variety of available R-BOX sizes means that we have an R-BOX that will fi t your process needs. Choose from standard internal widths of 3, 6, 9, and 12 inches. Designed to meet Type 4X and IP66 ratings, the R-BOX is resistant to ultraviolet rays and chemicals. Its high-impact structure protects instruments even in harsh fi eld conditions.

The R-BOX accommodates transmitters, meters, indicators, analyzers, integrators, and many other rail-mounted instruments. The variety of available R-BOX sizes means that we have an R-BOX that will fi t your process needs. Choose from standard internal widths of 3, 6, 9, and 12 inches. Designed to meet Type 4X and IP66 ratings, the R-BOX is resistant to ultraviolet rays and chemicals. Its high-impact structure protects instruments even in harsh fi eld conditions. -

The ROUTE-MASTER™ RM100 Series is an intrinsically-safe fieldbus power supply system providing galvanically-isolated and fieldbusconditioned power for FOUNDATION Fieldbus or PROFIBUS PA segments. Fieldbus devices may be connected into these segments only through RMA100 or RMA100C Device Couplers, and any intrinsicallysafe segment may only contain intrinsically-safe devices, that are approved for the appropriate Zone/Division of use and the appropriate Gas hazard.

The ROUTE-MASTER™ RM100 Series is an intrinsically-safe fieldbus power supply system providing galvanically-isolated and fieldbusconditioned power for FOUNDATION Fieldbus or PROFIBUS PA segments. Fieldbus devices may be connected into these segments only through RMA100 or RMA100C Device Couplers, and any intrinsicallysafe segment may only contain intrinsically-safe devices, that are approved for the appropriate Zone/Division of use and the appropriate Gas hazard. -

The UL Approved ECT-DIN 2-Wire Isolator is now available in a narrow 15mm aluminum housing. The thinner ECT-DIN 2-Wire Isolator with 15mm width retains the same General and Hazardous area approvals as the rest of the ECT family of isolators. It also has the same RFI/EMI protection and -40°C to 85°C operating temperature range. The ECT-DIN 2-Wire Isolator can be installed in hazardous locations and does not require installation in climate-controlled environments, making it perfect for more extreme locations.

The rugged narrow 15mm ECT DIN 2-Wire isolator and converter with 4-20mA, 1-5V and 0-10V inputs and 4-20mA output, permits more isolators to fit in cabinets and field enclosures where installation space is limited, saving space and money.” The ECT DIN 15mm narrow size allows more isolators to fit in cabinets and field enclosures where installation space is a premium. This is ideal for utilizing existing field mounted cabinets. The solid metal housing stands up to the continuous, daily rigors of process control and factory automation applications. An optional externally-mounted flange provides a secure mount, which ensures secure installation in high vibration environments. The ECT is UL approved Class I, Division 2, Groups A, B, C & D T4.

The rugged and reliable ECT family of isolators provides versatile choices to match the type of AC or DC power available at each location. ECT-DIN 2-wire Output-Loop powered models, ECT 2-wire Input-Loop powered models, or 4-wire (Line/Mains) Powered Isolators/Converters and Splitters are also available. The complete ECT family delivers reliable signal isolation and conversion solutions for the most demanding ambient and noisy installation conditions.

Download Data Sheet

The UL Approved ECT-DIN 2-Wire Isolator is now available in a narrow 15mm aluminum housing. The thinner ECT-DIN 2-Wire Isolator with 15mm width retains the same General and Hazardous area approvals as the rest of the ECT family of isolators. It also has the same RFI/EMI protection and -40°C to 85°C operating temperature range. The ECT-DIN 2-Wire Isolator can be installed in hazardous locations and does not require installation in climate-controlled environments, making it perfect for more extreme locations.

The rugged narrow 15mm ECT DIN 2-Wire isolator and converter with 4-20mA, 1-5V and 0-10V inputs and 4-20mA output, permits more isolators to fit in cabinets and field enclosures where installation space is limited, saving space and money.” The ECT DIN 15mm narrow size allows more isolators to fit in cabinets and field enclosures where installation space is a premium. This is ideal for utilizing existing field mounted cabinets. The solid metal housing stands up to the continuous, daily rigors of process control and factory automation applications. An optional externally-mounted flange provides a secure mount, which ensures secure installation in high vibration environments. The ECT is UL approved Class I, Division 2, Groups A, B, C & D T4.

The rugged and reliable ECT family of isolators provides versatile choices to match the type of AC or DC power available at each location. ECT-DIN 2-wire Output-Loop powered models, ECT 2-wire Input-Loop powered models, or 4-wire (Line/Mains) Powered Isolators/Converters and Splitters are also available. The complete ECT family delivers reliable signal isolation and conversion solutions for the most demanding ambient and noisy installation conditions.

Download Data Sheet