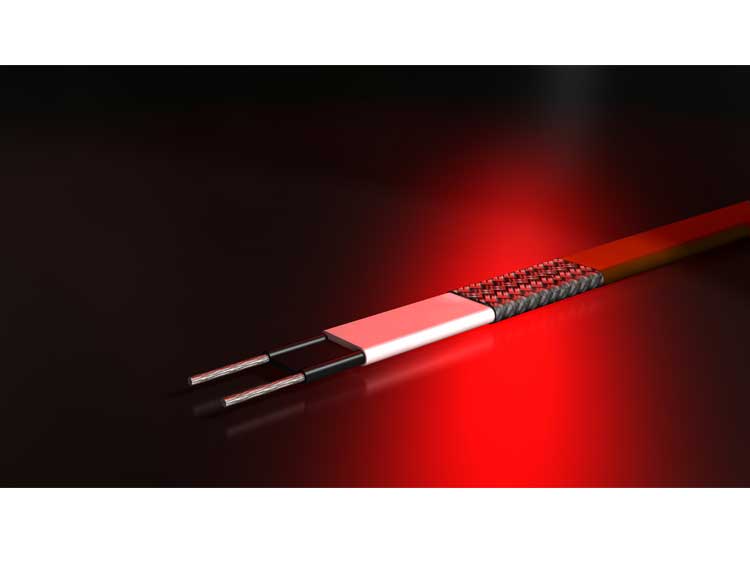

eltherms’ Clean Laser Seal technology takes Mineral Insulated (MI) Trace Heater assemblies to the next level.

Manufactured and assembled entirely from high quality stainless steel or Alloy 825, eltherm‘s revolutionary Clean Laser Seal Technology (CLS) guarantees performance and reliability in all industrial operations.

CLS offers today‘s best possible protection from stress corrosion cracking in applications in which aggressive chemicals may be present.

Stainless steel and Alloy 825 is the material of choice for temperature process control and ideally suited for freeze protection or viscosity control applications subject to periodic high temperature exposure.

Our proprietary clean laser sealing process provides a 100% stable, homogeneous system, resulting in a reliable and maintenance-free assembly.

Features:

- Factory terminated laser sealed technology

- All components in high quality stainless steel or Alloy 825

- High temperature resistance

- High chemical resistance

- High power output

- Flexible single or twin conductor configurations

- Moisture proof, may be immersed in fluid

Applications in Detail:

- Freeze/viscosity protection in industrial processes

- Process temperature maintain

- Vendor skids and process modules (cookie cutter custom units)

- Heat tracing of instrumentation and sample stations

- Vessel and trim tracing

- High temperature exposure

- Aseptic manufacturing conditions

- High watt density requirements

- Vacuum Processes

- Heat Treating Processes

- Heat tracing on instrumentation

Eltherm is a leading manufacturer of heated hoses and flexible, heated pipes. Heated pipes insures the transports of liquid and gaseous media without the loss of temperature.

Standard frost protection and process temperatures up to 450C can be implemented without any issues.

Applications:

Eltherm is a leading manufacturer of heated hoses and flexible, heated pipes. Heated pipes insures the transports of liquid and gaseous media without the loss of temperature.

Standard frost protection and process temperatures up to 450C can be implemented without any issues.

Applications: