-

300 SERIES NOSHOK MECHANICAL COMPACT SPDT PRESSURE SWITCHES WITH ADJUSTABLE HYSTERESIS are constructed with a rugged zinc-plated steel housing and process connection, and provide adjustable hysteresis. Utilizing a proven diaphragm or piston type sensing technology, it provides excellent reliability, repeatability, and affordability for use in many applications. The micro switch contacts are silver plated for extended service life and exceptional dependability. Switching functions are field adjustable, while under pressure, and it features an SPDT single changeover contact configuration. These switches are RoHs compliant.

300 SERIES NOSHOK MECHANICAL COMPACT SPDT PRESSURE SWITCHES WITH ADJUSTABLE HYSTERESIS are constructed with a rugged zinc-plated steel housing and process connection, and provide adjustable hysteresis. Utilizing a proven diaphragm or piston type sensing technology, it provides excellent reliability, repeatability, and affordability for use in many applications. The micro switch contacts are silver plated for extended service life and exceptional dependability. Switching functions are field adjustable, while under pressure, and it features an SPDT single changeover contact configuration. These switches are RoHs compliant. -

300/400/600/700/900 SERIES VAPOR ACTUATED REMOTE THERMOMETERS

NOSHOK VAPOR ACTUATED REMOTE THERMOMETERS operate using a temperature actuated liquid in the sensing element and a highly accurate, high quality pressure gauge to indicate media temperature. As the media temperature increases the capillary fill fluid vaporizes, causing an increase of pressure within the Bourdon tube, and activates the movement and pointer for proper indication. Dial scale graduations are non linear, therefore, the highest degree of accuracy and readability is found in the upper half of the scale.

300/400/600/700/900 SERIES VAPOR ACTUATED REMOTE THERMOMETERS

NOSHOK VAPOR ACTUATED REMOTE THERMOMETERS operate using a temperature actuated liquid in the sensing element and a highly accurate, high quality pressure gauge to indicate media temperature. As the media temperature increases the capillary fill fluid vaporizes, causing an increase of pressure within the Bourdon tube, and activates the movement and pointer for proper indication. Dial scale graduations are non linear, therefore, the highest degree of accuracy and readability is found in the upper half of the scale. -

3000 SERIES 80 CM2 NOMINAL DIAMETER HYDRAULIC LOAD CELLS

NOSHOK 80 CM2 NOMINAL DIAMETER HYDRAULIC LOAD CELLS are constructed from a high grade, corrosion resistant stainless steel and joined with a high quality NOSHOK pressure gauge or transducer to measure axial loads and bearing forces in turning and drilling machines, extruders and other compression force measurement applications. Accuracy levels range from ±0.125% full scale (BFSL) to ±1.5% full scale depending on the measuring instrument with measuring ranges from 360 lbf through 70,000 lbf.

3000 SERIES 80 CM2 NOMINAL DIAMETER HYDRAULIC LOAD CELLS

NOSHOK 80 CM2 NOMINAL DIAMETER HYDRAULIC LOAD CELLS are constructed from a high grade, corrosion resistant stainless steel and joined with a high quality NOSHOK pressure gauge or transducer to measure axial loads and bearing forces in turning and drilling machines, extruders and other compression force measurement applications. Accuracy levels range from ±0.125% full scale (BFSL) to ±1.5% full scale depending on the measuring instrument with measuring ranges from 360 lbf through 70,000 lbf. -

Our Pepperl+Fuchs Bebco EPS 3000 series, Type Y or Z / Ex pz purging system will purge and pressurize the protected enclosure and maintain pressure within the enclosure. The system reduces the classification within the protected enclosure from a Zone 2 to non-hazardous area.

Our Pepperl+Fuchs Bebco EPS 3000 series, Type Y or Z / Ex pz purging system will purge and pressurize the protected enclosure and maintain pressure within the enclosure. The system reduces the classification within the protected enclosure from a Zone 2 to non-hazardous area.

- DEMKO, ATEX, UL,cUL & FM classified

- Conforms to NFPA 496 and ISA 12.4 EN 50016, and ATEX standards

- For Type Y, Type Z, and Type pz applications

- Enclosure volumes to 250 cu. ft.(7.08 cu. m)

Type Ex pz purge system models - 3000 series

3003: Class I Enclosure Volumes ≤ 90 ft33004: Class I Enclosure Volumes ≤ 250 ft3 -

The Pepperl+Fuchs Bebco EPS 3000 series, Type Y purging system will purge and pressurize the protected enclosure and maintain pressure within the enclosure. The system reduces the classification within the protected enclosure from a Division 1 to a Division 2 area.

The Pepperl+Fuchs Bebco EPS 3000 series, Type Y purging system will purge and pressurize the protected enclosure and maintain pressure within the enclosure. The system reduces the classification within the protected enclosure from a Division 1 to a Division 2 area.

- UL, cUL & FM classified

- Conforms to NFPA 496 and ISA 12.4 standards

- For Type Y or Type Z applications

- Enclosure volumes to 250 cu. ft.(7.08 cu. m)

Type Y purge system models - 3000 series

3003: Class I Enclosure Volumes ≤ 90 ft3 3004: Class I Enclosure Volumes ≤ 250 ft3 -

The Pepperl+Fuchs 3000 series Type Z purging system will purge and pressurize the protected enclosure and maintain pressure within the enclosure. Suitable for Class 1, Division 2 to non-hazardous and Zone 2 to non-hazardous.

The Pepperl+Fuchs 3000 series Type Z purging system will purge and pressurize the protected enclosure and maintain pressure within the enclosure. Suitable for Class 1, Division 2 to non-hazardous and Zone 2 to non-hazardous.

- DEMKO, ATEX, UL, cUL & FM classified

- Conforms to NFPA 496 and ISA 12.4 EN 50016, and ATEX standards

- For Type Y, Type Z, and Type nP applications

- Enclosure volumes to 250 cu. ft.(7.08 cu. m)

Type Z purge system models - 3000 series

3003: Class I Enclosure Volumes ≤ 90 ft33004: Class I Enclosure Volumes ≤ 250 ft3 -

Download Datasheet

Download DatasheetStandard Features:

- Standard Pressure Rating with Metal Lower Housing

- Process Connection Sizes 1/4 inch NPT through 1 1/2 inch NPT

- Maximum Working Pressure 1,250 to 2,500 PSIG (8.63 to 17.25 Mpa) @ 100ºF (38ºC)

-

Download Datasheet

Download DatasheetStandard Features:

- 1 inch (25.40mm) and Larger

- Process Connect Sizes 1, 2 and 3 inches

- ASME/ANSI Flange Ratings up to 2,500lb

- Maximum Working Pressure Conforms to Flange Pressure-Temperature Rating per ASME/ANSI B16.5

- Flange Faces (125-250Ra Spiral Finish is standard)

- Raised Face, Flat Face, Ring Type Joint and Special Flange Faces are available

-

Standard Features:

- 3" (76.20mm) 150# and 3" (76.20mm) 300lb

- Process Connection Sizes 3" ASME/ANSI Flange Ratings 150# and 300# ... other flange ratings available

- Maximum Working Pressure Conforms to Flange Pressure-Temperature Ratings per ASME/ANSI B16.5

- Flange Faces, Raised Face and Flat Face

Download Datasheet

-

Standard Features:

- 1 1/2 inch (25.40mm) through 8 inch

- ASME/ANSI Flange Ratings up to 2,500lb

- Maximum Working Pressure Conforms to Flange Pressure-Temperature Rating per ASME/ANSI B16.5

- Flange Faces (125-250Ra Spiral Finish is standard)

- Raised Face, Flat Face , Ring Type Joint and Special Flange Faces are available

-

Standard Features:

- Standard Pressure Rating with Metal Lower Housing 3 inches and larger

- All Pipe Schedules per ASME/ANSI B16.10 or B36.19

- Maximum Working Pressure Conforms to Pipe Schedule Ratings as calculated by ASME/ANSI B31.1 Equation "4" @ 100 ºF (38ºC)

Download Datasheet

-

Standard Features:

- Standard Pressure Rating with Metal Lower Housing 4 inches and larger

- All Pipe Schedules per ASME/ANSI B16.10 or B36.19

- Maximum Working Pressure Conforms to Pipe Schedule Ratings as calculated by ASME/ANSI B31.1 Equation "4" @ 100 ºF (38ºC)

Download Datasheet

-

Standard Features:

- Standard Pressure Rating with Metal Lower Housing 1/4 inches through 1 inch

- All Pipe Schedules per ASME/ANSI B36.10 or B36.19

- Maximum Working Pressure Conforms to Pipe Schedule Ratings as calculated by ASME/ANSI B31.1 Equation "4" @ 100 ºF (38ºC)

Download Datasheet

-

Download Datasheet

Download DatasheetStandard Features:

- Standard Pressure Rating with Metal Lower 1/4 inches through 1 inch

- All Pipe Schedules per ASME/ANSI B36.10 or B36.19

- Maximum Working Pressure Conforms to Pipe Schedule Ratings as calculated by ASME/ANSI B31.1 Equation "4" @ 100 ºF (38ºC)

-

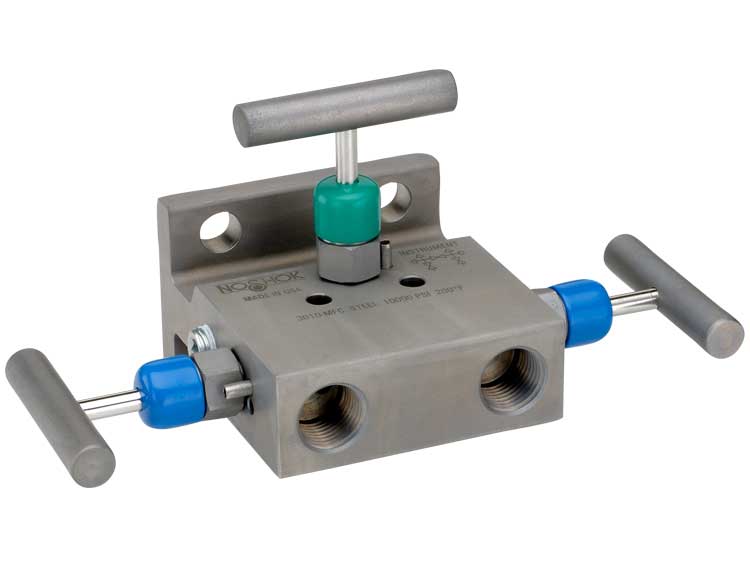

3010/3110 SERIES 3-VALVE DIFFERENTIAL PRESSURE MANIFOLD VALVES

NOSHOK 3-VALVE DIFFERENTIAL PRESSURE MANIFOLD VALVES are designed for use with differential pressure transmitters incorporating two isolation valves and an equalizing valve in differential pressure measurement. These valves are available in block, single flange or double flange connection for remote or direct installation. The soft seat design features a replaceable Delrin® seat with straight through porting for bi-directional flow and easy roddable cleaning.

3010/3110 SERIES 3-VALVE DIFFERENTIAL PRESSURE MANIFOLD VALVES

NOSHOK 3-VALVE DIFFERENTIAL PRESSURE MANIFOLD VALVES are designed for use with differential pressure transmitters incorporating two isolation valves and an equalizing valve in differential pressure measurement. These valves are available in block, single flange or double flange connection for remote or direct installation. The soft seat design features a replaceable Delrin® seat with straight through porting for bi-directional flow and easy roddable cleaning. -

Standard Features:

- Standard Pressure Rating with Metal Lower Housing

- Process Connection Sizes 1/4 " NPTF through 1 1/2" NPTF

- Maximum Pressure Rating 1250, 2500 PSIG (8.63, 17.25Mpa) @ 100ºF (38ºC)

Download Datasheet

-

Standard Features:

- 2" (50.80mm) and Larger

- Process Connection Sizes 2" through 3" ASME/ANSI Flange Rating up to 2500lb

- Maximum Working Pressure Conforms to Flange Pressure-Temperature Ratings per ASME/ANSI B16.5

- Flange Faces (125-250Ra Spiral Finish is standard)

- Raised Face , Flat Face , Ring Type Joint and Special Flange Faces are available

Download Datasheet

-

3540 SERIES TENSION AND COMPRESSION FORCE TRANSDUCERS NOSHOK TENSION AND COMPRESSION FORCE TRANSDUCERS are available in many different sizes and shapes to fit almost any application. They are available in measuring ranges as small as 0 kN to 1 kN and as high as 0 kN to 500 kN with an accuracy of ±0.2% of full scale Cn. Several outputs are available in both amplified and unamplified to interface with most electrical systems. Many versions are manufactured from stainless steel which makes them suitable for installation in harsh environments. Applications for use of this product include cable or rod tension, weight measurement, overload protection, clamping force and fill level measurement.

3540 SERIES TENSION AND COMPRESSION FORCE TRANSDUCERS NOSHOK TENSION AND COMPRESSION FORCE TRANSDUCERS are available in many different sizes and shapes to fit almost any application. They are available in measuring ranges as small as 0 kN to 1 kN and as high as 0 kN to 500 kN with an accuracy of ±0.2% of full scale Cn. Several outputs are available in both amplified and unamplified to interface with most electrical systems. Many versions are manufactured from stainless steel which makes them suitable for installation in harsh environments. Applications for use of this product include cable or rod tension, weight measurement, overload protection, clamping force and fill level measurement. -

400 SERIES MECHANICAL HEAVY-DUTY PRESSURE SWITCHES

NOSHOK MECHANICAL HEAVY-DUTY PRESSURE SWITCHES provide excellent repeatability and features a robust design for applications requiring maximum accuracy under extreme loads. With a switching point setting that remains stable for years, this switch converts pneumatic and hydraulic pressure into switching functions, and depending on the type of connection, it can easily be used as a N.C., N.O. or SPDT contact. The switching point is fully adjustable and includes a locking mechanism. This switch is fitted with DIN EN175301-803 Form A connectors for fast and easy installation. It is also available with a socket with an LED for easier switch point adjustment and visual status indication, or without the socket and an M12 x 1 (4-pin) electrical connection.

-

400/500 SERIES DRY AND LIQUID FILLED ALL STAINLESS STEEL GAUGES NOSHOK DRY AND LIQUID FILLED ALL STAINLESS STEEL GAUGES are corrosion-resistant fillable dry or liquid-filled gauges. They are used in corrosive service world-wide where ruggedness and reliability are critical. Typical applications include chemical processing, oil field & offshore, paper mills, agriculture plants, marine, and water & wastewater. Extreme high pressure ranges available. Ammonia gauges available in certain ranges.

400/500 SERIES DRY AND LIQUID FILLED ALL STAINLESS STEEL GAUGES NOSHOK DRY AND LIQUID FILLED ALL STAINLESS STEEL GAUGES are corrosion-resistant fillable dry or liquid-filled gauges. They are used in corrosive service world-wide where ruggedness and reliability are critical. Typical applications include chemical processing, oil field & offshore, paper mills, agriculture plants, marine, and water & wastewater. Extreme high pressure ranges available. Ammonia gauges available in certain ranges. -

400/500 SERIES STANDARD NEEDLE VALVES NOSHOK STANDARD NEEDLE VALVES are the work horses of the industry. The 400 Series’ metal-to-metal hard seat design is pressure rated to 10,000 psi @ 200 °F and helium leak tested to 1x10-4 ml/s for guaranteed performance and reliability. The 500 Series valves are fitted with a precision molded, replaceable Delrin® soft seat which is the key to the bubble tight seal. They have a maximum pressure rating of 6,000 psi @ 200 °F with straight through porting for bi-directional, high capacity flow and easy roddable cleaning. The all 316 stainless steel blow out proof stem provides greater service life and provides a secondary stem seal in the full open position. On the 400 Series, the stem and the one piece bonnet threads are rolled for greater strength and ease of operation. Both the 400 and 500 Series feature stem seal below the threads to protect against corrosion and galling.

400/500 SERIES STANDARD NEEDLE VALVES NOSHOK STANDARD NEEDLE VALVES are the work horses of the industry. The 400 Series’ metal-to-metal hard seat design is pressure rated to 10,000 psi @ 200 °F and helium leak tested to 1x10-4 ml/s for guaranteed performance and reliability. The 500 Series valves are fitted with a precision molded, replaceable Delrin® soft seat which is the key to the bubble tight seal. They have a maximum pressure rating of 6,000 psi @ 200 °F with straight through porting for bi-directional, high capacity flow and easy roddable cleaning. The all 316 stainless steel blow out proof stem provides greater service life and provides a secondary stem seal in the full open position. On the 400 Series, the stem and the one piece bonnet threads are rolled for greater strength and ease of operation. Both the 400 and 500 Series feature stem seal below the threads to protect against corrosion and galling. -

4001V ANACONDA INDUSTRIAL HOSE PUMPS. Exceptional self-priming capabilities make the 4001V Series an ideal choice for hard-to-handle chemicals such as sodium hypochlorite, hydrogen peroxide or viscous polymers.

Self priming pump can be run dry without damage. Flow rates from 1 to 330 GPH. Pressures to 100 psi.

4001V ANACONDA INDUSTRIAL HOSE PUMPS. Exceptional self-priming capabilities make the 4001V Series an ideal choice for hard-to-handle chemicals such as sodium hypochlorite, hydrogen peroxide or viscous polymers.

Self priming pump can be run dry without damage. Flow rates from 1 to 330 GPH. Pressures to 100 psi. -

The Pepperl+Fuchs 5000Q series Ex pz purge is a small and compact purge system. The 5000Q operates by controlling and monitoring compressed instrument air or inert gas through the protected enclosure(s) to remove and prevent the accumulation of flammable gas, vapors, or dust. It is a powerful purge system designed to meet your Zone 2, 22 installation requirements.

The 5000Q series control unit features these main parts:

The Pepperl+Fuchs 5000Q series Ex pz purge is a small and compact purge system. The 5000Q operates by controlling and monitoring compressed instrument air or inert gas through the protected enclosure(s) to remove and prevent the accumulation of flammable gas, vapors, or dust. It is a powerful purge system designed to meet your Zone 2, 22 installation requirements.

The 5000Q series control unit features these main parts:

- Up to 3 PT100 RTD’s connected for temperature monitoring or control

- LCD for viewing programming and operation modes

- Field configurable through menu driven programs for most applications

-

5301/5308 SERIES LOAD PINS

NOSHOK LOAD PINS utilize our proven thin film sensor technology laser welded directly to the measuring instrument. This technology gives us the ability to offer accuracies up to ±0.5% and minimize the disadvantages seen in the bonded foil versions (temperature drifts and long term stability). They are available in many different sizes and shapes for the direct replacement of existing bolts where a force measurement may need to be taken. Various output signals are available to integrate with almost any electrical system. Common applications for load pins are force measurement on roller bearings, industrial weighing, measurement of cable tension on hoists and overload protection on cranes.

5301/5308 SERIES LOAD PINS

NOSHOK LOAD PINS utilize our proven thin film sensor technology laser welded directly to the measuring instrument. This technology gives us the ability to offer accuracies up to ±0.5% and minimize the disadvantages seen in the bonded foil versions (temperature drifts and long term stability). They are available in many different sizes and shapes for the direct replacement of existing bolts where a force measurement may need to be taken. Various output signals are available to integrate with almost any electrical system. Common applications for load pins are force measurement on roller bearings, industrial weighing, measurement of cable tension on hoists and overload protection on cranes.