CX Domestic Immersion Heaters were developed as high quality replacements for the most commonly used heater types. The CXC is available in a range of styles, including 2.5" (64 mm) square flange with tinned copper sheath, 1" (25 mm) tapered brass plug with copper sheath, 1" (25 mm) non-tapered brass plug with copper sheath and round flange with zinc plated copper sheath. The CXI is available with a 2.5" (64 mm) square flange with Incoloy® sheath. Elements are epoxy-coated to protect the heater from moisture and other contaminants that can lead to premature element failure.

CX Domestic Immersion Heaters were developed as high quality replacements for the most commonly used heater types. The CXC is available in a range of styles, including 2.5" (64 mm) square flange with tinned copper sheath, 1" (25 mm) tapered brass plug with copper sheath, 1" (25 mm) non-tapered brass plug with copper sheath and round flange with zinc plated copper sheath. The CXI is available with a 2.5" (64 mm) square flange with Incoloy® sheath. Elements are epoxy-coated to protect the heater from moisture and other contaminants that can lead to premature element failure. -

CX Domestic Immersion Heaters were developed as high quality replacements for the most commonly used heater types. The CXC is available in a range of styles, including 2.5" (64 mm) square flange with tinned copper sheath, 1" (25 mm) tapered brass plug with copper sheath, 1" (25 mm) non-tapered brass plug with copper sheath and round flange with zinc plated copper sheath. The CXI is available with a 2.5" (64 mm) square flange with Incoloy® sheath. Elements are epoxy-coated to protect the heater from moisture and other contaminants that can lead to premature element failure.

CX Domestic Immersion Heaters were developed as high quality replacements for the most commonly used heater types. The CXC is available in a range of styles, including 2.5" (64 mm) square flange with tinned copper sheath, 1" (25 mm) tapered brass plug with copper sheath, 1" (25 mm) non-tapered brass plug with copper sheath and round flange with zinc plated copper sheath. The CXI is available with a 2.5" (64 mm) square flange with Incoloy® sheath. Elements are epoxy-coated to protect the heater from moisture and other contaminants that can lead to premature element failure. -

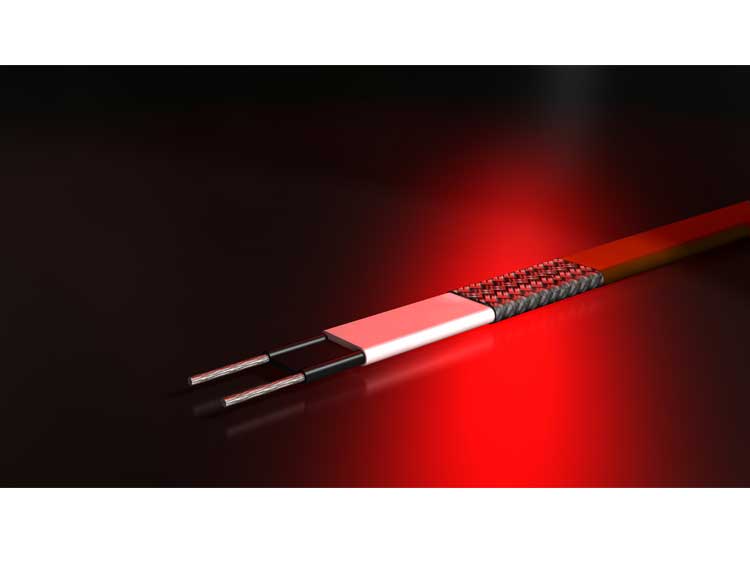

Self-regulating heating cables consist of two parallel bus wires embedded in a networked plastic heating element, doped with surrounding carbon particles. If the temperature increases during operation, the plastic expands due to molecular expansion and the distance between the carbon particles increases. Resistance increases and output drops. When it cools down, this process is reversed and output increases.

This physical property provides several benefits, including the ability to overlap the self-regulating cable and installation without the requirement of a temperature cut-out device.

Benefits:

Self-regulating heating cables consist of two parallel bus wires embedded in a networked plastic heating element, doped with surrounding carbon particles. If the temperature increases during operation, the plastic expands due to molecular expansion and the distance between the carbon particles increases. Resistance increases and output drops. When it cools down, this process is reversed and output increases.

This physical property provides several benefits, including the ability to overlap the self-regulating cable and installation without the requirement of a temperature cut-out device.

Benefits:

- Self-regulating with adaptable output

- Various temperature range applications

- High chemical resistance

- No temperature regulation or limiting required

- Easy to lay and to install

- Can be cut to length off the roll

-

Eltherm is a leading manufacturer of heated hoses and flexible, heated pipes. Heated pipes insures the transports of liquid and gaseous media without the loss of temperature.

Standard frost protection and process temperatures up to 450C can be implemented without any issues.

Applications:

Eltherm is a leading manufacturer of heated hoses and flexible, heated pipes. Heated pipes insures the transports of liquid and gaseous media without the loss of temperature.

Standard frost protection and process temperatures up to 450C can be implemented without any issues.

Applications:

Analyzer technology

- Holding temperature / frost protection; up to 450C

- Typical nominal diameters; 4-10mm

Industrial Applications / Heated Pressure Hoses

- Holding temperature / frost protection; up to 250C

- Typical nominal diameters; 8-100 mm

-

Corrective action prompted by early warning of generator overheating can mean the difference between a brief shutdown for minor repairs and a major overhaul involving weeks or even months of costly downtime. E/One pioneered the development of the Generator Condition Monitor (GCM) and in more than 1,500 applications worldwide, operators have the opportunity of taking corrective action if and when a critical situation occurs

Corrective action prompted by early warning of generator overheating can mean the difference between a brief shutdown for minor repairs and a major overhaul involving weeks or even months of costly downtime. E/One pioneered the development of the Generator Condition Monitor (GCM) and in more than 1,500 applications worldwide, operators have the opportunity of taking corrective action if and when a critical situation occurs -

PP1H and PP2H Peristaltic Pump Chemical Feed Prepackaged Systems . SELF PRIMING WITH BUILT IN SPILL AND LEAK PREVENTION The PP1H and PP2H (dual pump model) an ideal choice for hard-to-handle chemicals such as sodium hypochlorite, hydrogen peroxide or viscous polymers. Flow rates from .004 to 98 gallons per hour (with dual pump-head option.)

PP1H and PP2H Peristaltic Pump Chemical Feed Prepackaged Systems . SELF PRIMING WITH BUILT IN SPILL AND LEAK PREVENTION The PP1H and PP2H (dual pump model) an ideal choice for hard-to-handle chemicals such as sodium hypochlorite, hydrogen peroxide or viscous polymers. Flow rates from .004 to 98 gallons per hour (with dual pump-head option.) -

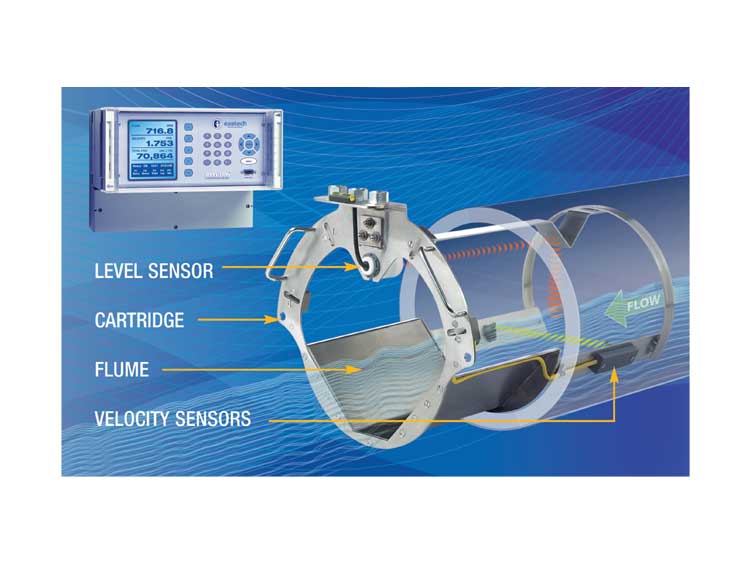

The Cartridge Meter is the first open channel flowmeter to utilize hybrid technology. The new technology combines a traceable U.S. Bureau of Reclamation flume/level system for low flow applications with the more accurate EPA proven transit-time chordal velocity method for high flow applications. This new hybrid technology system allows for precise and highly accurate flow measurement during extremely low flows, high flows, surcharges, reverse flows, stagnation and non-uniform hydraulic profiles.

The Cartridge Meter is the first open channel flowmeter to utilize hybrid technology. The new technology combines a traceable U.S. Bureau of Reclamation flume/level system for low flow applications with the more accurate EPA proven transit-time chordal velocity method for high flow applications. This new hybrid technology system allows for precise and highly accurate flow measurement during extremely low flows, high flows, surcharges, reverse flows, stagnation and non-uniform hydraulic profiles. -

The Vantage 4000 is shipped to the field factory pre-programmed to the conditions set forth by the customer. Preprogramming specifications are electronically confirmed on the display of the transmitter. If changes to the meter’s factory pre-programming is required, re-programming can simply be accomplished on the meter keypad or through the Auto- Programming feature. This feature allows plant personnel to re-program the Vantage 4000 by simply downloading the revised flow data from a PC or laptop directly into the meter.• Water & Wastewater

• Sewage Treatment

• Acids & Toxic Liquids

• Petroleum Products

• HVAC & Irrigation

The Vantage 4000 is shipped to the field factory pre-programmed to the conditions set forth by the customer. Preprogramming specifications are electronically confirmed on the display of the transmitter. If changes to the meter’s factory pre-programming is required, re-programming can simply be accomplished on the meter keypad or through the Auto- Programming feature. This feature allows plant personnel to re-program the Vantage 4000 by simply downloading the revised flow data from a PC or laptop directly into the meter.• Water & Wastewater

• Sewage Treatment

• Acids & Toxic Liquids

• Petroleum Products

• HVAC & Irrigation -

The F010 is a local weather-proof indicator with large 26mm (1”) high digits which displays the actual flow rate. The measuring and time unit to be displayed below the flow rate are simply selected through an alphanumeric configuration menu. The configuration of K-factors or Span and number of decimals is done through software functions without any sensitive DIP-switches or trimmers.

The F010 is a local weather-proof indicator with large 26mm (1”) high digits which displays the actual flow rate. The measuring and time unit to be displayed below the flow rate are simply selected through an alphanumeric configuration menu. The configuration of K-factors or Span and number of decimals is done through software functions without any sensitive DIP-switches or trimmers. -

The F126-EG flow computer has been developed to calculate corrected gas volume at normal conditions. The corrected volumetric flow is calculated by measuring the uncorrected volumetric flow, actual line temperature and pressure which are processed with the equations stored in the flow computer. A compressibility factor can be set to approach a real gas behavior. The reference conditions can be defined as desired (e.g. 15°C or 60°F and 1.013 bar).

The display shows the compensated flow rate, total, accumulated total and the actual line temperature and pressure. On-screen engineering units like Nm³ are easily configured from a comprehensive selection.

The F126-EG flow computer has been developed to calculate corrected gas volume at normal conditions. The corrected volumetric flow is calculated by measuring the uncorrected volumetric flow, actual line temperature and pressure which are processed with the equations stored in the flow computer. A compressibility factor can be set to approach a real gas behavior. The reference conditions can be defined as desired (e.g. 15°C or 60°F and 1.013 bar).

The display shows the compensated flow rate, total, accumulated total and the actual line temperature and pressure. On-screen engineering units like Nm³ are easily configured from a comprehensive selection. -

The F120 single loop controller has been designed to offer outstanding control performance and provide a reliable solution for a wide variety of flow control applications. The single loop flow controller accepts most pulse inputs from flow meters and has a 4 - 20 mA output for controlling a valve or pump. The F120 is part of the Fluidwell process controller family and is the alternative for local control loops.

The F120 single loop controller has been designed to offer outstanding control performance and provide a reliable solution for a wide variety of flow control applications. The single loop flow controller accepts most pulse inputs from flow meters and has a 4 - 20 mA output for controlling a valve or pump. The F120 is part of the Fluidwell process controller family and is the alternative for local control loops. -

The batch controllers of the N-Series are much more advanced compared to our F-Series and D-Series batch controllers. The N-Series distinguishes itself from other batch controllers by its very easy to use numerical keypad. Selecting and entering multiple preset values with the easy to press keys is astonishingly simple. The display is designed for batch processes: at a glance, the operator is aware of the indicated switch points and the actual state of the process. For your convenience the preset and the actual value with their engineering units are displayed simultaneously.

The batch controllers of the N-Series are much more advanced compared to our F-Series and D-Series batch controllers. The N-Series distinguishes itself from other batch controllers by its very easy to use numerical keypad. Selecting and entering multiple preset values with the easy to press keys is astonishingly simple. The display is designed for batch processes: at a glance, the operator is aware of the indicated switch points and the actual state of the process. For your convenience the preset and the actual value with their engineering units are displayed simultaneously.