E/One's Generator Gas Analyzer (GGA) for hydrogen-cooled generators is a triple-range sensor/analyzer that provides continuous monitoring of gas purity during all phases of generator operation.

E/One's Generator Gas Analyzer (GGA) for hydrogen-cooled generators is a triple-range sensor/analyzer that provides continuous monitoring of gas purity during all phases of generator operation. -

Corrective action prompted by early warning of generator overheating can mean the difference between a brief shutdown for minor repairs and a major overhaul involving weeks or even months of costly downtime. E/One pioneered the development of the Generator Condition Monitor (GCM) and in more than 1,500 applications worldwide, operators have the opportunity of taking corrective action if and when a critical situation occurs

Corrective action prompted by early warning of generator overheating can mean the difference between a brief shutdown for minor repairs and a major overhaul involving weeks or even months of costly downtime. E/One pioneered the development of the Generator Condition Monitor (GCM) and in more than 1,500 applications worldwide, operators have the opportunity of taking corrective action if and when a critical situation occurs -

Conoflow’s Commandaire® Positioner is a top mounted, integral positioner used with piston or spring and diaphragm actuators. Utilizing a force balance principle this unit provides proportional positioning of an actuator with stroke lengths up to 10”. The completely enclosed design eliminates exposed levers or linkages making the Commandaire® Positioner rugged and reliable.

Conoflow’s Commandaire® Positioner is a top mounted, integral positioner used with piston or spring and diaphragm actuators. Utilizing a force balance principle this unit provides proportional positioning of an actuator with stroke lengths up to 10”. The completely enclosed design eliminates exposed levers or linkages making the Commandaire® Positioner rugged and reliable.Specifications:

- Supply Pressure Effect: Less than 0.15% per PSI

- Power Amplification - (Proportional Band): Less than 5.0% deviation in signal or stroke produces full output pressure change

- Ambient Temperature Range: -20°F to +150°F (-29°C to +66°C)

- Flow Capacity (Dynamic): Up to 5.0 SCFM (0.14 m3/min) in either direction with a 100 PSI (690 kPa) supply

- Air Consumption (Static): 0.3 SCFM at 40 PSI supply (0.008 m3/min at 276 kPa)

- Air Supply: 20 PSI to 100 PSI (138 to 690 kPa)

- Controller Signal: All standard spans and split ranges available

- Zero Suppression: 0 to 18 PSI (0 to 124 kPa)

- Control Actions: Direct or reverse, top or bottom loading

- Actuator Travels: 1/4" to 10" (6.35 to 254 mm)

- Connections: 1/4" NPT

- Adjustment: Zero adjust is external and can be made without tools

- Mounting: Mounted integrally to top of cylinder or spring and diaphragm actuator with 2-1/4" dimension between positioner mounting flange and actuator stem in retracted position

- Weight: Approximate Shipping Weight: 2-3/4 lbs. (1.25 Kg)

-

Conoflow’s Pneumatic Lever Actuators are rugged and powerful units used to automatically position dampers, louvers, variable pitch fans and to make various mechanical adjustments to process machinery. Low profile (only 18” high) requires less headroom. A sturdy ductile iron yoke with large mounting base provides rigid mounting. The steel lever arm has eight take-off positions for stroke flexibility.The Lever Actuator is a combination piston actuator and lever mechanism. These actuators are available in piston diameters of 6” and 8” with a maximum lever travel of 12”. Force produced is a function of the supply pressure which may be varied from 20 to 100 PSI (137 to 690 kPa) and the lever take-off position.The actuator assembly is completely enclosed to protect all moving parts from corrosive atmospheres and adverse weather conditions. All exterior parts are coated with a corrosion-resistant paint.

Conoflow’s Pneumatic Lever Actuators are rugged and powerful units used to automatically position dampers, louvers, variable pitch fans and to make various mechanical adjustments to process machinery. Low profile (only 18” high) requires less headroom. A sturdy ductile iron yoke with large mounting base provides rigid mounting. The steel lever arm has eight take-off positions for stroke flexibility.The Lever Actuator is a combination piston actuator and lever mechanism. These actuators are available in piston diameters of 6” and 8” with a maximum lever travel of 12”. Force produced is a function of the supply pressure which may be varied from 20 to 100 PSI (137 to 690 kPa) and the lever take-off position.The actuator assembly is completely enclosed to protect all moving parts from corrosive atmospheres and adverse weather conditions. All exterior parts are coated with a corrosion-resistant paint. -

Conoflow’s Pneumatic Piston Actuators are compact units designed to function in today’s high performance instrument systems. Piston diameters of 3” to 12.5” are available with standard strokes up to 10” (for stroke lengths greater than 10”, consult the factory). Integral positioners are standard for modulating service.Force produced is a function of the supply pressure which can be varied from 20 to 100 PSI (138 to 690 kPa). Fast stroking speeds are made possible through the use of a high capacity positioner coupled with a unique cushion-loading regulator. The GB50 Series Piston Actuators are designed for use in corrosive atmospheres or adverse weather conditions.

Conoflow’s Pneumatic Piston Actuators are compact units designed to function in today’s high performance instrument systems. Piston diameters of 3” to 12.5” are available with standard strokes up to 10” (for stroke lengths greater than 10”, consult the factory). Integral positioners are standard for modulating service.Force produced is a function of the supply pressure which can be varied from 20 to 100 PSI (138 to 690 kPa). Fast stroking speeds are made possible through the use of a high capacity positioner coupled with a unique cushion-loading regulator. The GB50 Series Piston Actuators are designed for use in corrosive atmospheres or adverse weather conditions. -

The E/One Gas Station is a modular approach that combines monitoring and control systems onto a single skid, customized to meet specific power plant requirements and budgets. Gas Station modules include:

• Main gas supply manifold and associated controls

• Gas purity monitoring

• Overheat monitoring

• Dew point monitoring

• Gas drying

• Partial discharge monitoring

• Seal oil system monitoring and control

• Customized annunciator panels

The E/One Gas Station is a modular approach that combines monitoring and control systems onto a single skid, customized to meet specific power plant requirements and budgets. Gas Station modules include:

• Main gas supply manifold and associated controls

• Gas purity monitoring

• Overheat monitoring

• Dew point monitoring

• Gas drying

• Partial discharge monitoring

• Seal oil system monitoring and control

• Customized annunciator panels -

FMS Series electromagnetic flow meter easily connects too many common controllers.

Economical small-diameter flow sensors for reliable full-pipe flow measurement with low-cost and fast installation.

FMS05 / FMS10 / FMS20 FEATURES

• Accuracy to +/-2.0%

• Flows from 0.5 to 951 GPH

• Pressures to 145 PSI

• Fluid temperatures to 140 F

• Compatible with pulsating flows

• Easy to install union end connections

• Outputs: Pulse, Error, Alarm.

FMS Series electromagnetic flow meter easily connects too many common controllers.

Economical small-diameter flow sensors for reliable full-pipe flow measurement with low-cost and fast installation.

FMS05 / FMS10 / FMS20 FEATURES

• Accuracy to +/-2.0%

• Flows from 0.5 to 951 GPH

• Pressures to 145 PSI

• Fluid temperatures to 140 F

• Compatible with pulsating flows

• Easy to install union end connections

• Outputs: Pulse, Error, Alarm. -

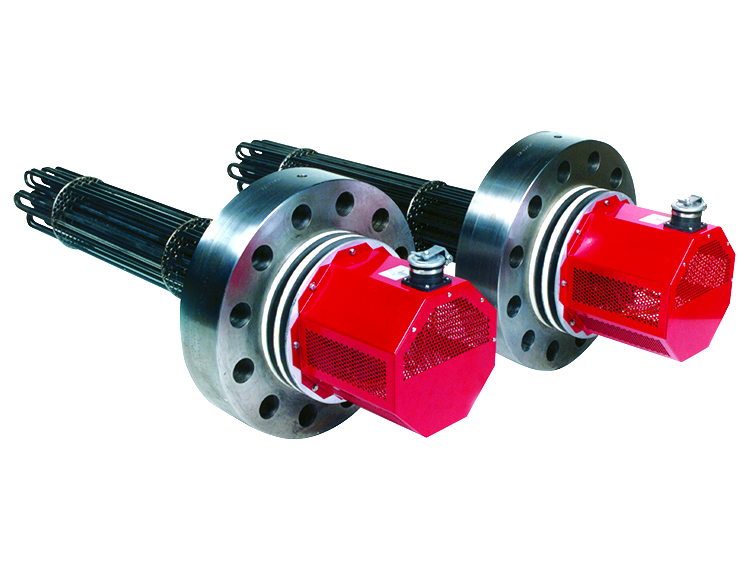

CXC Flange Heaters are used primarily for water heating applications and feature copper sheathed elements silver brazed to a steel flange.

CXI Flange Heaters are well suited for heating water, especially in hot water and steam boilers, as well as heating mildly corrosive solutions in rinse tanks, spray washers, etc. The heater features incoloy® sheathed elements silver brazed to steel flange.

CXF Flange Heaters are used primarily for heating applications involving oils, gases and mildly corrosive liquids. They are constructed of incoloy® sheathed elements silver brazed to a steel flange.

CXC Flange Heaters are used primarily for water heating applications and feature copper sheathed elements silver brazed to a steel flange.

CXI Flange Heaters are well suited for heating water, especially in hot water and steam boilers, as well as heating mildly corrosive solutions in rinse tanks, spray washers, etc. The heater features incoloy® sheathed elements silver brazed to steel flange.

CXF Flange Heaters are used primarily for heating applications involving oils, gases and mildly corrosive liquids. They are constructed of incoloy® sheathed elements silver brazed to a steel flange. -

The F195 has been developed for the valve position indication and monitoring in hydraulic systems. By using a bi-directional flow meter to measure the volume displaced by the actuator, an accurate position of the system is calculated.

The display shows the position as a percentage as well as with the text "open" and "closed" for the minimum and maximum positions. As standard, the analog output mirrors the percentage displayed which can be used to transmit the valve position. The usual difficulties encountered in such applications include: very low flows, vibration, and thermal expansion of the oil and high ambient temperatures.

The F195 has been developed for the valve position indication and monitoring in hydraulic systems. By using a bi-directional flow meter to measure the volume displaced by the actuator, an accurate position of the system is calculated.

The display shows the position as a percentage as well as with the text "open" and "closed" for the minimum and maximum positions. As standard, the analog output mirrors the percentage displayed which can be used to transmit the valve position. The usual difficulties encountered in such applications include: very low flows, vibration, and thermal expansion of the oil and high ambient temperatures. -

The F040 is a straight forward temperature indicator with large 26mm (1") high digits. The measuring unit to be displayed below the temperature is simply selected through an alphanumeric configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user-friendly solution! The configuration of the Span, off-set and number of decimals is done through software functions, without any sensitive DIP-switches or trimmers.

The F040 is a straight forward temperature indicator with large 26mm (1") high digits. The measuring unit to be displayed below the temperature is simply selected through an alphanumeric configuration menu. No adhesive labels have to be put on the outside of the enclosure: a weather proof and user-friendly solution! The configuration of the Span, off-set and number of decimals is done through software functions, without any sensitive DIP-switches or trimmers.