The high-performance IPT 2 Current-to-Pressure (I/P) Transmitter converts a current signal to a pneumatic signal so that an electronic-based system such as a DCS, PLC, or PC can control a pneumatic actuator, valve, or damper drive. Available models accept a wide range of current inputs (4-20mA, 4-12mA, and 12-20mA) and provide a proportional pneumatic signal (3-15psig, 0.2-1 Bar, 20-100kPA, etc.).

The high-performance IPT 2 Current-to-Pressure (I/P) Transmitter converts a current signal to a pneumatic signal so that an electronic-based system such as a DCS, PLC, or PC can control a pneumatic actuator, valve, or damper drive. Available models accept a wide range of current inputs (4-20mA, 4-12mA, and 12-20mA) and provide a proportional pneumatic signal (3-15psig, 0.2-1 Bar, 20-100kPA, etc.). -

The high-performance IPT 2 Current-to-Pressure (I/P) Transmitter converts a current signal to a pneumatic signal so that an electronic-based system such as a DCS, PLC, or PC can control a pneumatic actuator, valve, or damper drive. Available models accept a wide range of current inputs (4-20mA, 4-12mA, and 12-20mA) and provide a proportional pneumatic signal (3-15psig, 0.2-1 Bar, 20-100kPA, etc.).

The high-performance IPT 2 Current-to-Pressure (I/P) Transmitter converts a current signal to a pneumatic signal so that an electronic-based system such as a DCS, PLC, or PC can control a pneumatic actuator, valve, or damper drive. Available models accept a wide range of current inputs (4-20mA, 4-12mA, and 12-20mA) and provide a proportional pneumatic signal (3-15psig, 0.2-1 Bar, 20-100kPA, etc.). -

These 2-wire (loop-powered) I/P transmitters accept a current signal (such as 4-20mA) from a DCS, PLC or PC-based control system. They convert the current signal to a pneumatic signal (3-15psig, 0.2-1bar, 20-100kPa, etc.) to provide precise, proportional control of valves, actuators and other pneumaticallycontrolled devices. The economical IPH2 (Type 4X) is watertight, dust-protected, and resistant to corrosion and chemicals. In addition to meeting Type 3X/4X requirements, the IPX2 can be installed in explosionproof environments. Both units are available with an optional coalescing fi lter/regulator that combines an air fi lter and miniature supply line regulator with a pressure gauge that reads in both psig and bars.

These 2-wire (loop-powered) I/P transmitters accept a current signal (such as 4-20mA) from a DCS, PLC or PC-based control system. They convert the current signal to a pneumatic signal (3-15psig, 0.2-1bar, 20-100kPa, etc.) to provide precise, proportional control of valves, actuators and other pneumaticallycontrolled devices. The economical IPH2 (Type 4X) is watertight, dust-protected, and resistant to corrosion and chemicals. In addition to meeting Type 3X/4X requirements, the IPX2 can be installed in explosionproof environments. Both units are available with an optional coalescing fi lter/regulator that combines an air fi lter and miniature supply line regulator with a pressure gauge that reads in both psig and bars. -

The rugged IPF Field-Mounted Current-to-Pressure Transmitter is designed specifically for installation in harsh environments. The two-wire IPF accepts a 4-20mA or 10-50mA input. It converts the input to a 3-15psig, 0.2-1bar, 15-3psig or 1-0.2bar pneumatic output signal, or to a wide variety of other commonly used pneumatic outputs (see Specifications for details). This versatility allows the IPF to interface with just about any kind of process control instrumentation including chart recorders, data loggers, panel meters, multiplexers, controllers and computers. The IPF can either be surface-mounted or mounted directly on a two-inch (vertical or horizontal) pipe. Two different types of housings are offered. The standard WP housing provides 1/2-inch NPT female wire entry threads while the metric WPM housing provides M20X1.5 female wire entry threads. The IPF transmitter is also available with an optional coalescing filter/regulator that combines both an air filter and a miniature supply line regulator. For more information on

The rugged IPF Field-Mounted Current-to-Pressure Transmitter is designed specifically for installation in harsh environments. The two-wire IPF accepts a 4-20mA or 10-50mA input. It converts the input to a 3-15psig, 0.2-1bar, 15-3psig or 1-0.2bar pneumatic output signal, or to a wide variety of other commonly used pneumatic outputs (see Specifications for details). This versatility allows the IPF to interface with just about any kind of process control instrumentation including chart recorders, data loggers, panel meters, multiplexers, controllers and computers. The IPF can either be surface-mounted or mounted directly on a two-inch (vertical or horizontal) pipe. Two different types of housings are offered. The standard WP housing provides 1/2-inch NPT female wire entry threads while the metric WPM housing provides M20X1.5 female wire entry threads. The IPF transmitter is also available with an optional coalescing filter/regulator that combines both an air filter and a miniature supply line regulator. For more information on -

The Pepperl+Fuchs brand ecom introduces Ex-Handy 10 - the new generation of intrinsically safe 4G/LTE feature phones for a broad variety of applications - from pure communication to Push-to-Talk or lone worker protection.

The Pepperl+Fuchs brand ecom introduces Ex-Handy 10 - the new generation of intrinsically safe 4G/LTE feature phones for a broad variety of applications - from pure communication to Push-to-Talk or lone worker protection.

The Ex-Handy 10 with Android 8.1 operating system, is the ideal companion for innovative Industry 4.0 applications in hazardous areas. With IP68 and Gorilla® Glass you can operate the Ex-Handy 10 in the roughest of environments. With a 5-year product lifecycle and global Ex-certifications to meet all requirements, it provides a low risk investment to the user.

With customer-specific configurations and customizations, it also handles the most demanding of situations.

Features:

- IP68 – dust- and waterproof housing + MIL-STD-810G standard

- Worldwide approvals for Zone 1/21, 2/22 & Class 1 / Div 1 & Div 2

- Protected in all situations: Special buttons for Push-To-Talk (PTT) & Lone Worker Protection (LWP)

- Always and everywhere applicable: Excellent readability of the display even in direct sunlight and a long battery life.

Technical Data:

- Android™ 8.1

- 8 MP rear camera with auto focus

- 4G / LTE -standard (SIM unlocked and free); Nano SIM

-

From simple signal conditioning, to sensor-level I/O, to complex distributed intelligence, the versatile I/O EQUATION STATION ® is your solution. Even though it’s the same size as a typical process instrument, this multifunction I/O module configures to handle both routine, and one-of-a-kind, applications:

From simple signal conditioning, to sensor-level I/O, to complex distributed intelligence, the versatile I/O EQUATION STATION ® is your solution. Even though it’s the same size as a typical process instrument, this multifunction I/O module configures to handle both routine, and one-of-a-kind, applications: -

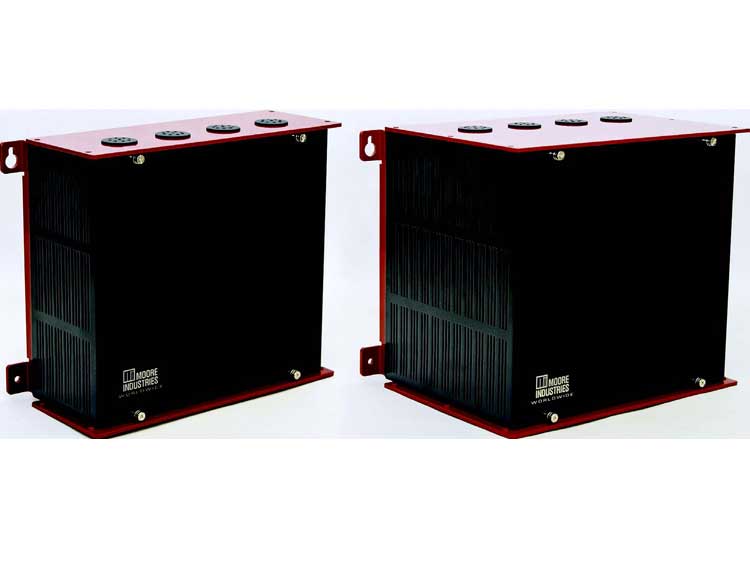

When Hydrogen purity drops, windage losses and operating costs increase, resulting in lost revenue and profitability. Gas purity is also a critical life safety issue, making monitoring for potentially explosive levels essential. E/One's Hydrogen Control Cabinet (HCC) was designed specifically for monitoring and controlling hydrogen purity in GE generators that utilize scavenging seal oil systems. The HCC contains two independent analyzers that monitor hydrogen purity from both the turbine-end seal drain enlargement and the collector-end seal drain enlargement. Designed to be used in a hazardous location, the HCC has the ability to automatically increase the amount of hydrogen gas bled from the generator. It's also an easy replacement for your old hydrogen control cabinet. Featuring digital displays, warnings and alarms, the HCC works with all GE and non-GE control systems.

When Hydrogen purity drops, windage losses and operating costs increase, resulting in lost revenue and profitability. Gas purity is also a critical life safety issue, making monitoring for potentially explosive levels essential. E/One's Hydrogen Control Cabinet (HCC) was designed specifically for monitoring and controlling hydrogen purity in GE generators that utilize scavenging seal oil systems. The HCC contains two independent analyzers that monitor hydrogen purity from both the turbine-end seal drain enlargement and the collector-end seal drain enlargement. Designed to be used in a hazardous location, the HCC has the ability to automatically increase the amount of hydrogen gas bled from the generator. It's also an easy replacement for your old hydrogen control cabinet. Featuring digital displays, warnings and alarms, the HCC works with all GE and non-GE control systems. -

Conoflow’s HP700 Series regulator is a two-stage, high purity unit designed to provide constant outlet pressure regardless of inlet pressure fluctuations. This unit is available in either brass or stainless steel construction. Maximum supply pressure rating for either material is 3500 PSIG (24.2 MPa). To provide optimum performance in specific applications, this unit is offered with relieving, non-relieving, and tied (non-relieving) diaphragm options.Typical applications for the HP700 regulator are gas chromatography, calibration systems, cylinder gases, and precise regulation of corrosive and non-corrosive media. Adjustment within each of five available ranges is made with a standard large handwheel. A wrench style knob with a locking device and a “T” bar handle are available as optional adjustments. This unit is supplied with 1/4” inlet and outlet connections. Inlet and outlet gauge ports (1/4” NPT) are standard. High purity internal connections and VCR, Vacuseal and Ultra Seal welded fittings are optional. Captured bonnets for both stages are standard. This regulator is designed for reliability with an absolute minimum of maintenance.The characteristics are a result of Conoflow’s high standards of manufacturing and years of experience as a leading manufacturer of pneumatic instrumentation.

Conoflow’s HP700 Series regulator is a two-stage, high purity unit designed to provide constant outlet pressure regardless of inlet pressure fluctuations. This unit is available in either brass or stainless steel construction. Maximum supply pressure rating for either material is 3500 PSIG (24.2 MPa). To provide optimum performance in specific applications, this unit is offered with relieving, non-relieving, and tied (non-relieving) diaphragm options.Typical applications for the HP700 regulator are gas chromatography, calibration systems, cylinder gases, and precise regulation of corrosive and non-corrosive media. Adjustment within each of five available ranges is made with a standard large handwheel. A wrench style knob with a locking device and a “T” bar handle are available as optional adjustments. This unit is supplied with 1/4” inlet and outlet connections. Inlet and outlet gauge ports (1/4” NPT) are standard. High purity internal connections and VCR, Vacuseal and Ultra Seal welded fittings are optional. Captured bonnets for both stages are standard. This regulator is designed for reliability with an absolute minimum of maintenance.The characteristics are a result of Conoflow’s high standards of manufacturing and years of experience as a leading manufacturer of pneumatic instrumentation. -

ITT Conoflow’s HP635 Series unit is a high-flow, high-purity regulator that is designed as a purge gas regulator and may be used in high purity gas systems involving corrosive and toxic media. All wetted components are of a 316 Stainless Steel construction having a maximum 35Ra surface finish. An optional brass model (NPT port only) is available for inert gas service.This unit has a large main valve providing a flow capacity of Cv=1.8 at the valve. Connections are 1/2” NPT or 1/2” Tube Stubs with either style having a maximum supply pressure rating of 500 psig. Outlet pressure ranges of 0-25, 0-50, 0-100, 0-150 and 0-200 psig (0-0.173, 0-0.345, 0-0.69, 0-1.04, and 0-138 MPa) are available. The HP635 Regulator is offered with an inboard and across the seat leakage specification of 2 x 10-8 atm. cc/sec Helium. Also, there is an adjustable stop that may be set to limit pressure control settings for specific application requirements.

ITT Conoflow’s HP635 Series unit is a high-flow, high-purity regulator that is designed as a purge gas regulator and may be used in high purity gas systems involving corrosive and toxic media. All wetted components are of a 316 Stainless Steel construction having a maximum 35Ra surface finish. An optional brass model (NPT port only) is available for inert gas service.This unit has a large main valve providing a flow capacity of Cv=1.8 at the valve. Connections are 1/2” NPT or 1/2” Tube Stubs with either style having a maximum supply pressure rating of 500 psig. Outlet pressure ranges of 0-25, 0-50, 0-100, 0-150 and 0-200 psig (0-0.173, 0-0.345, 0-0.69, 0-1.04, and 0-138 MPa) are available. The HP635 Regulator is offered with an inboard and across the seat leakage specification of 2 x 10-8 atm. cc/sec Helium. Also, there is an adjustable stop that may be set to limit pressure control settings for specific application requirements. -

ITT Conoflow’s HP610 is a high purity, self-contained, spring-loaded, pressure reducing regulator. This unit is designed for use in applications requiring high flow rates and the ability to relieve outlet media pressure. Non-relieving models are also available.The 316 Stainless Steel constructed unit has a maximum supply pressure rating to 250 PSIG (1.73 MPa). The convoluted 316 Stainless Steel diaphragm provides accurate and reliable regulation over a control setting range of 0 - 50 PSIG (0 - 0.35 MPa).The HP610 has one ¼” NPT inlet connection and two ¼” NPT outlet connections. Both outlet ports provide the same flow capacity with the central port generally being used as a gauge port.

ITT Conoflow’s HP610 is a high purity, self-contained, spring-loaded, pressure reducing regulator. This unit is designed for use in applications requiring high flow rates and the ability to relieve outlet media pressure. Non-relieving models are also available.The 316 Stainless Steel constructed unit has a maximum supply pressure rating to 250 PSIG (1.73 MPa). The convoluted 316 Stainless Steel diaphragm provides accurate and reliable regulation over a control setting range of 0 - 50 PSIG (0 - 0.35 MPa).The HP610 has one ¼” NPT inlet connection and two ¼” NPT outlet connections. Both outlet ports provide the same flow capacity with the central port generally being used as a gauge port.