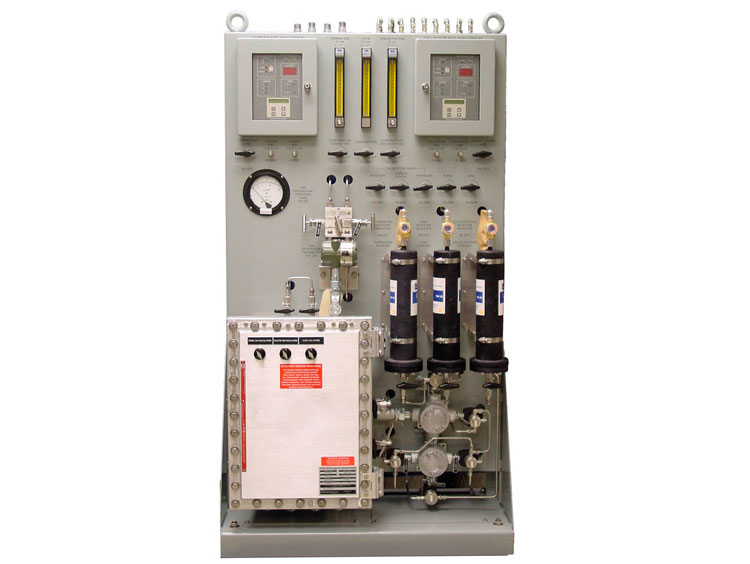

Environment One's Dual Hydrogen Control Panel (DHCP) was designed specifically for monitoring GE's scavenging seal oil generators. The DHCP contains two independent analyzers that monitor the turbine-end seal drain enlargement, collector-end seal oil drain enlargement with both valving for manual or DCS operation for checking casing purity of the generator.

Environment One's Dual Hydrogen Control Panel (DHCP) was designed specifically for monitoring GE's scavenging seal oil generators. The DHCP contains two independent analyzers that monitor the turbine-end seal drain enlargement, collector-end seal oil drain enlargement with both valving for manual or DCS operation for checking casing purity of the generator. E/One’s focus is on generator applications — for both hydrogen-cooled and air-cooled units — and for over 40 years, the company has led the way in the development of condition monitoring and predictive maintenance systems for electric power producers. Today, more than 3500 of our systems stand vigil worldwide. Our mission is helping generator manufacturers and plant owners/operators optimize safety, increase unit efficiency, and avoid costly disruption to operations

-

Environment One's Dual Hydrogen Control Panel (DHCP) was designed specifically for monitoring GE's scavenging seal oil generators. The DHCP contains two independent analyzers that monitor the turbine-end seal drain enlargement, collector-end seal oil drain enlargement with both valving for manual or DCS operation for checking casing purity of the generator.

Environment One's Dual Hydrogen Control Panel (DHCP) was designed specifically for monitoring GE's scavenging seal oil generators. The DHCP contains two independent analyzers that monitor the turbine-end seal drain enlargement, collector-end seal oil drain enlargement with both valving for manual or DCS operation for checking casing purity of the generator. -

The E/One Gas Station is a modular approach that combines monitoring and control systems onto a single skid, customized to meet specific power plant requirements and budgets. Gas Station modules include:

• Main gas supply manifold and associated controls

• Gas purity monitoring

• Overheat monitoring

• Dew point monitoring

• Gas drying

• Partial discharge monitoring

• Seal oil system monitoring and control

• Customized annunciator panels

The E/One Gas Station is a modular approach that combines monitoring and control systems onto a single skid, customized to meet specific power plant requirements and budgets. Gas Station modules include:

• Main gas supply manifold and associated controls

• Gas purity monitoring

• Overheat monitoring

• Dew point monitoring

• Gas drying

• Partial discharge monitoring

• Seal oil system monitoring and control

• Customized annunciator panels -

Corrective action prompted by early warning of generator overheating can mean the difference between a brief shutdown for minor repairs and a major overhaul involving weeks or even months of costly downtime. E/One pioneered the development of the Generator Condition Monitor (GCM) and in more than 1,500 applications worldwide, operators have the opportunity of taking corrective action if and when a critical situation occurs

Corrective action prompted by early warning of generator overheating can mean the difference between a brief shutdown for minor repairs and a major overhaul involving weeks or even months of costly downtime. E/One pioneered the development of the Generator Condition Monitor (GCM) and in more than 1,500 applications worldwide, operators have the opportunity of taking corrective action if and when a critical situation occurs -

When Hydrogen purity drops, windage losses and operating costs increase, resulting in lost revenue and profitability. Gas purity is also a critical life safety issue, making monitoring for potentially explosive levels essential. E/One's Hydrogen Control Cabinet (HCC) was designed specifically for monitoring and controlling hydrogen purity in GE generators that utilize scavenging seal oil systems. The HCC contains two independent analyzers that monitor hydrogen purity from both the turbine-end seal drain enlargement and the collector-end seal drain enlargement. Designed to be used in a hazardous location, the HCC has the ability to automatically increase the amount of hydrogen gas bled from the generator. It's also an easy replacement for your old hydrogen control cabinet. Featuring digital displays, warnings and alarms, the HCC works with all GE and non-GE control systems.

When Hydrogen purity drops, windage losses and operating costs increase, resulting in lost revenue and profitability. Gas purity is also a critical life safety issue, making monitoring for potentially explosive levels essential. E/One's Hydrogen Control Cabinet (HCC) was designed specifically for monitoring and controlling hydrogen purity in GE generators that utilize scavenging seal oil systems. The HCC contains two independent analyzers that monitor hydrogen purity from both the turbine-end seal drain enlargement and the collector-end seal drain enlargement. Designed to be used in a hazardous location, the HCC has the ability to automatically increase the amount of hydrogen gas bled from the generator. It's also an easy replacement for your old hydrogen control cabinet. Featuring digital displays, warnings and alarms, the HCC works with all GE and non-GE control systems. -

Environment One's standard Generator Gas Analyzer (GGA) can also be supplied in a portable configuration. The PGA incorporates the same hydrogen gas sensor/analyzer and system electronics found in our other hydrogen gas purity systems. The PGA is specifically intended for use in non-hazardous environments and/or as an emergency back-up in the event a power plant's primary purity monitoring system is compromised.

Environment One's standard Generator Gas Analyzer (GGA) can also be supplied in a portable configuration. The PGA incorporates the same hydrogen gas sensor/analyzer and system electronics found in our other hydrogen gas purity systems. The PGA is specifically intended for use in non-hazardous environments and/or as an emergency back-up in the event a power plant's primary purity monitoring system is compromised.